Inventory Redistribution Review

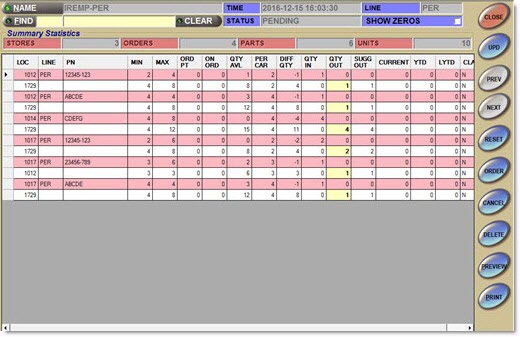

The Inventory Redistribution Review screen is used to review the selected results of the criteria that was run in the Inventory Redistribution Setup screen, allow suggested quantities to be edited before the 'Order' button is clicked to generate the purchase orders.

Once the setup criteria are established in the Inventory Redistribution Setup screen and the system runs the calculations to determine the stock moves, the Inventory Redistribution Review screen displays to allow the ability to review selected results of the criteria that were run and allow suggested quantities to be edited before generating the purchase orders.

In each understocked store, a PO can be created for each overstocked store from which parts are being ordered. The PO has a 'Source' of 'Xfer' and the 'Vendor' is the store from which stock is being ordered. When the PO is transmitted, a sales order is created in the selling store. (The Account controls whether the sales order is a pick or final invoice.) The overstocked store may edit the sales order. The understocked store receives an ASN when the overstocked store prints the transfer invoice.

When a run is kicked-off, the run is saved and can be used to kick off orders presently or a later time.

Menu Path: Inventory, Inventory Distribution, Inventory Redistribution Setup, Inventory Redistribution Setup screen, populate and click 'Run', Inventory Redistribution Review screen

Menu Path: Inventory, Inventory Distribution, Inventory Redistribution Review, Inventory Redistribution Review screen

Menu Path: Purchasing, Inventory Distribution, Inventory Redistribution Review, Inventory Redistribution Review screen

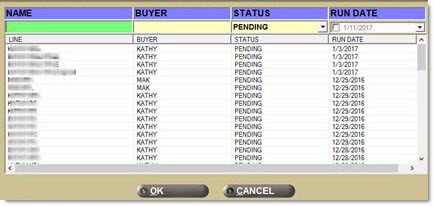

Displays the 'Employee ID' and selected 'Line Code'. Click the button to display the 'Browse Inventory Redistribution' window to access current or previous runs.

All currently available Inventory Redistribution "Runs" display. Click on a run to populate the Inventory Redistribution Review screen with its results.

Find

Displays a part number. Click the button to display the 'Find Part' window to search for a part number, when clicked. Note: All parts in the line display in the window, not just those that are in the Redistribution grid.

Clear

Clears the information in the 'Find' text box.

Time

Indicates the date and time the current run was kicked off.

Displays the 'Status' of the run.

Options are:

-

'Aborted' - Processing was aborted by PartsWatch Admin staff after 'Run' was clicked. This is a manual process and would only be done if there were technical issues, or the process was requested to be canceled.

-

'Canceled' - 'Run' was clicked, data was generated, the redistribution data was reviewed and it was decided to cancel it by using the 'Cancel' button without clicking 'Order'. The data is given a 'Status' of 'Cancel' but can be reviewed later, if desired.

-

'Failed' - Processing failed after either the 'Run' process or 'Order' process.

-

'Finished' - 'Order' was clicked. Orders were generated and queued for transmission.

-

'Init' - Creation of transfer orders was initiated after clicking 'Order' button.

-

'Ordering' - System is in the process of creating transfer orders.

-

'Pending' - Redistribution data has been generated using the 'Run' button. Transfer orders have not yet been generated by clicking 'Order'.

-

'Running' - 'Run' was clicked and the system is in the process of generating the suggested quantities for the Review screen.

Line

Displays the 'Line Code' selected for distribution.

Show Zeros

Determines whether to show parts that are not being moved.

All stores are listed even if stock is not being moved to or from that store, when checked. However, the part must be being moved in at least one store to be included in the display.

Only stores with stock being moved is listed, when unchecked. (Default)

Summary Statistics

Stores

Displays the number of stores with parts being moved in or out.

Orders

Displays the number of orders that will be generated when 'Order' is clicked. Note: Multiple orders can be generated in one store. For example, if Store 2 is understocked and is obtaining parts from three stores, three purchase orders will result.

Parts

Displays the number of unique part numbers being ordered.

Units

Displays the total part quantity being moved in or out.

Grid

Suggested moves for the lowest-numbered understocked store displays first. For that store, each understocked part is listed with its information, followed by the information for that part for any overstocked store(s) in store number order. This sequence repeats for each understocked store.

Understocked ('To') store rows display in pink. Overstocked ('From') store rows display in white.

If a part is bring moved to a location from multiple locations, each move displays on a separate row.

Loc

Displays the location or Store Number the part is being moved into or out of.

Line

Displays the line code of the part.

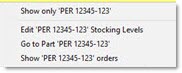

Right-click a part to display a pop-up to access the Main Part Entry screen, Stocking Level Edit screen, and various other screens to view or edit part information, if Security Permissions allow.

Displays the minimum stocking level of the part as set up in the part record.

Max

Displays the maximum stocking level of the part as set up in the part record.

Ord Pt

Displays the Order Point of the part as set up in the part record.

On Ord

Displays the On Order + Back Order quantities from existing orders for the part.

Qty Avl

Displays the current 'Qty Avl' from the part number.

Per Car

Displays the 'Per Car' quantity from the part record.

Diff Qty

Displays the difference between 'Qty Avl' and order point ('Min', 'Max', and 'Order Point'), depending on which was selected for over or under).

A negative quantity indicates an understocked part. A positive quantity indicates an overstocked part.

Qty In

Displays the quantity the system is suggesting moving to a particular understocked store for a particular part.

Qty Out

Displays the quantity the system is suggesting moving out. Defaults to 'Sugg Out'. Edit the suggested amount if a different quantity (including zero), if desired.

Sugg Out

Displays the quantity the system is suggesting pulling from a particular store for a particular part.

Current

Displays the Current part sales history quantities.

YTD

Displays the Year-To-Date part sales history quantities.

LYTD

Displays the Last Year-To-Date part sales history quantities.

Class

Displays the Class Code of the part.

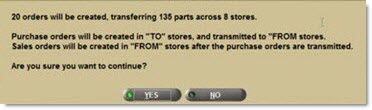

Initiates the creation of purchase orders.

When clicked, the 'Inventory Redistribution' pop-up displays.

Click 'Yes' to begin creating orders. Click 'No' to return to the Inventory Redistribution Review screen without creating orders.

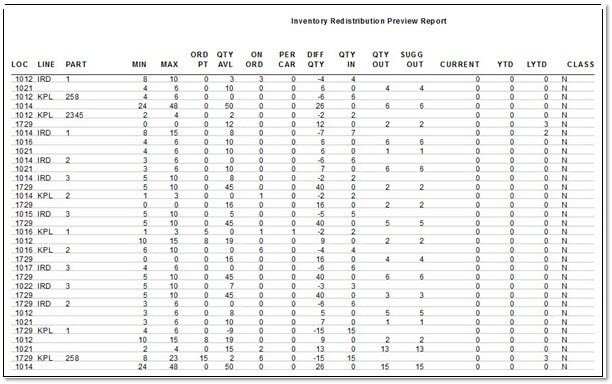

Inventory Redistribution Review Report

Click 'Preview' or 'Print' to output the 'Inventory Redistribution Preview Report'.

Procedure to Generate Inventory Redistriubution Preview Report

To produce an 'Inventory Redistribution Preview Report', which recommends how to redistribute stock among stores, follow the steps below:

-

From the Menu, select Inventory, Inventory Distribution, Inventory Redistribution Setup. The Inventory Redistribution Setup screen displays.

-

Select the desired filters for invoking a redistribution in the 'Parts Criteria' section.

-

Select the desired options in the 'Select Options' section to establish overstock and understock criteria.

-

Select the stores in the 'Select To Stores' and 'Select From Stores' sections to use to process the redistribution.

-

Click 'Run'. The calculations for stock moves is kicked off and the Inventory Redistribution Review screen displays to review the selected results of the criteria that was run before generating the purchase orders.

-

Click 'Preview' to review the 'Inventory Redistribution Preview Report'.

-

Click 'Print' to print the 'Inventory Redistribution Preview Report'.

Procedure to Generate Inventory Redistribution Preview Report for a Saved Run

To produce an 'Inventory Redistribution Preview Report', which recommends how to redistribute stock among stores, from a saved run, follow the steps below:

-

From the Menu, select Inventory, Inventory Distribution, Inventory Redistribution Review. The Inventory Redistribution Review screen displays.

-

Click 'Name'. The 'Browse Inventory Redistribution' window displays.

-

Select the desired saved run and click 'Ok'. The grid in the Inventory Redistribution Review screen populates with the saved run information.

-

Click 'Preview' to review the 'Inventory Redistribution Preview Report'.

-

Click 'Print' to print the 'Inventory Redistribution Preview Report'.