Customer Sourcing Overview

1. Parts can be sourced if there is not sufficient sell quantity.

About Customer Sourcing

“Sourcing” is a feature of Point-Of-Sale that allows stores to see what is available in the warehouse, other stores in the company, or in outside sources, and to order the parts at the same time when the store does not have sufficient sell quantity. Depending on the modifier used, parts with insufficient sell quantity must be sourced in order to complete the sale.

A default modifier used for sourcing can be set up in the 'Available Sourcing Modifiers' field as well as all other modifiers available for sourcing per supplier.

If available, the following modifiers are user for sourcing:

- 'B' = BO BUYOUT - Sufficient sell quantity must be acquired using customer sourcing. Part histories are updated by the sale, however, stock quantities are not affected.

- 'H' = DS DROPSHIP - Parts can be sold with insufficient sell quantity without going through customer sourcing. Neither part histories nor stock quantities are affected by the sale.

- 'XF' = TRANSFER - Used for multi-store company-owned vendors. The modifier behaves just like the BO BUYOUT modifier, but since it is a different code, "transfers" that are not considered regular sourced sales can be reported separately.

Parts with insufficient sell quantity can be sold without sourcing using the following modifiers:

- 'F' = FORWARD - Used instead of the BO BUYOUT modifier with sufficient sell quantity since sourcing is not forced at the time of the sale, and like the BO BUYOUT modifier, part histories are updated, however, stock quantities are not affected.

- 'P' = PURCHASE - Used instead of the DS DROPSHIP modifier with sufficient sell quantity since sourcing is not forced at the time of the sale, and like the DS DROPSHIP modifier, part histories are updated, however, stock quantities are not affected.

There are three ways to source parts with insufficient sell quantity at the time of the sale:

-

"Quick Sourcing" is used to order a single item at a time during the sale.

-

Advanced Sourcing is used to order multiple items on the ticket at the same time.

-

Default Sourcing uses a predefined source for items with insufficient sell quantity without having to go through the sourcing process.

Click here to learn more about Quick Sourcing.

Default Sourcing

If enabled, a default source per supplier will "source" the part for the default source without going through the sourcing process.

If the selected modifier is set up as the default sourcing modifier in the 'Available Sourcing Modifiers' field for the supplier, and if the 'DEFAULT SOURCE FOR BO/DS' field is set up with a supplier, adding a part with insufficient sell quantity to the ticket uses the default source instead of opening the Quick Sourcing or ADVANCED SOURCING screen. The part is added to the invoice grid with the default source and following the sourcing process, a purchase order is created when the 'FINISH' button is clicked or the invoice is finalized.

To select a source other than the default, right-click and select 'QUICK SOURCING' or 'ADVANCE SOURCING' from the menu or click the 'SOURCE-IT' button and follow the sourcing process.

Click here to learn more about Advanced Sourcing

2. Click the 'FINISH' button to create the purchase order.

When an item with insufficient sell has been added to the invoicing grid with the 'BUYOUT' or 'DROPSHIP' modifier, a 'FINISH' button displays in the lower-left row with the process buttons.

Finish Button Process

The Finish process generates a purchase order for sourced items without finalizing the invoice. When sourcing is finished, whether or not additional parts have been added to the sales order, click the 'FINISH' button when done.

The 'FINISH' button is used to create a purchase order and an invoice reference for the sourced ticket until the sourced parts are acquired and the sales order finalized. The ticket and the purchase order are tracked as a "SOURCED" order.

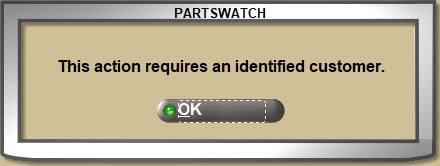

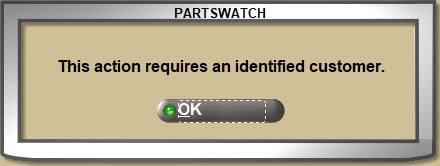

Unidentified Cash Customers: Cash customers must be identified. A prompt opens to identify the customer. Click 'OK' and identify the customer to continue.

On Account / Identified Cash Customers: If one or more parts with insufficient quantity have not been sourced, a pop-up opens stating that the ticket cannot be finished without sourcing.

- Answer 'NO' and focus returns to the sell line to continue with the sales order.

- Answer 'YES' and if a single item must be sourced, the 'INSUFFICIENT QUANTITY – SOURCING' (Quick Sourcing) window opens if enabled. If disabled, the 'INSUFFICIENT QUANTITY' window opens. If more than a single part must be sourced, the ADVANCED SOURCING screen opens.

Source the part or parts to continue.

If all parts have been sourced, click the 'FINISH' button and a prompt opens to continue.

Identified Cash Customers: The prompt asks whether or not to order the items and finalize the invoice.

- Answer 'NO' and focus returns to the sell line.

- Answer 'YES' and the 'Invoice Tender' window opens to take a 'DEPOSIT' or to pay in full. The order is created for the sourced items, the invoice prints and is tracked in the 'CASH DRAWER'.

When the part is available, if a 'DEPOSIT' was taken open the ticket from the 'REF' button and complete tender. If the invoice was finalized, no further action is needed.

On Account Customers: The prompt asks whether or not to create the purchase order.

- Answer 'NO' and focus returns to the sell line to continue with the sales order.

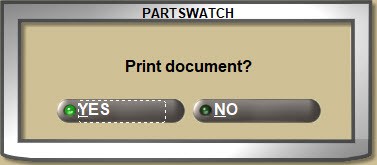

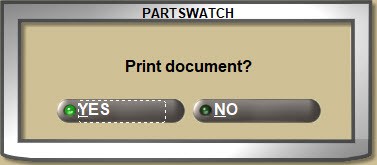

- Answer 'YES' and a prompt asks whether or not to print the ticket.

- Answer 'NO' and the order is created without printing the reference document.

- Answer 'YES' and the document prints as a reference only and the order is created.

Whether using Quick Sourcing or Advanced Sourcing functionality, if the selected source’s quantity is less than the order quantity, a prompt will open to either edit the order quantity or order it anyway.

When the part is available, open the ticket from the 'REF' button and finalize the invoice.

Finalize Process

Tickets with sourced items can either be finalized without waiting for the sourced parts to be received first, or forcing the 'FINISH' button to be clicked and waiting for the purchase order to be received before the ticket can be finalized is controlled by the:

Depending on the setups, if enabled, click the 'INVOICE/SLIP' or 'ON ACCT/PAY NOW' button instead of the 'FINISH' button to 'AUTOSOURCE' the parts.

If the ticket is finalized instead of "finished", the purchase order created for the sourced items is tracked as an 'AUTOSRC' (auto-sourced) order.

Unidentified Cash Customer: The customer does not have to be identified. If one or more parts with insufficient quantity have not been sourced, a pop-up opens asking whether to open the sourcing screen or not.

- Answer 'NO' and focus returns to the sell line to continue with the sales order.

- Answer 'YES' and if a single item must be sourced, the 'INSUFFICIENT QUANTITY – SOURCING' (Quick Sourcing) window opens if enabled. If disabled, the 'INSUFFICIENT QUANTITY' window opens. If more than a single part must be sourced, the ADVANCED SOURCING screen opens.

Source the part or parts to continue.

- Answer 'NO' and focus returns to the sell line to continue with the sales order.

- Answer 'YES' and the invoice will be finalized and printed and depending on the button clicked, the 'INVOICE PAY OPTIONS' window will open to continue or the invoice will be finalized and tracked to the account.

Additional setups are available to determine how sourcing is handled at Point-of-Sale.

Setups per Supplier:

'USE BUY QTY RULE'

If enabled for a supplier, sourced items must be ordered in multiples of the 'BUY QTY RULE' set up on the part.

Sourced purchase orders are created and transmitted with quantities rounded to increments of the 'BUY QTY'.

'SOURCING COST LEVEL'

If a cost level is entered for the supplier, sourced parts are tracked with that cost level. If a cost level is not selected, then the regular pricing is calculated.

'SOURCING + OR - PERCENT'

Used in conjunction with the 'SOURCING COST LEVEL' field. If a cost level is selected, enter a percent to raise the cost (+) or lower the cost (-) tracked for the sourced part.

'USE SUPPLIER COST FOR SRCD ORDERS'

If enabled, when a stock check is made to the supplier during sourcing, the cost returned from the supplier is tracked for the sourced part. Uses the cost from the part record when disabled or when the supplier does not provide a cost.

'DEFAULT SOURCING MODIFIER'

Select the default modifier that will be used when a part with insufficient sell quantity is added to the sell line and tracked with the sale. If set to 'NOT SELECTED', the '(BO) BUYOUT' modifier will be used as the default.

'SOURCING SELL LEVEL'

If a sell level is entered for the supplier, parts sourced using any POS sourcing method recalculates the 'EACH' price based on this level. If the sell level is selected, that level is always applied to sourced items for this supplier regardless of any PRICE PLAN SETUP price levels.

If the sell level is not selected, then sell price is calculated from the regular sell level.

'SOURCING SELL + OR - PERCENT'

Used in conjunction with the 'SOURCING SELL LEVEL' field. If a sell level is selected, enter a percent to raise the sell price (+) or lower the sell price (-) calculated for the sourced part.

Available Sourcing Modifiers / Default

Check each modifier that will be available for customer sourcing at Point-of-Sale. Check the default modifier that will be used each time a source item is added to a sales order. The modifier can be changed as needed during the sale.

Setups per Source:

'ALLOW AUTO PROCESS COMMERCIAL ACCOUNTS'

If enabled, open tickets can be finalized for commercial accounts without waiting for the sourced parts to be received first.

'ALLOW AUTO PROCESS RETAIL ACCOUNTS'

If enabled, open tickets can be finalized for retail cash customers without waiting for the sourced parts to be received first.

'TIME OUT MINUTES'

Depending on the 'TIMEOUT MINUTES' value, should a ticket with sourced items be open beyond the time limit, clicking the 'FINISH' button will prompt that the ticket must be re-sourced.

Click 'OK' and resource the items to continue.

The default is 30 minutes and can be set to '999' minutes or '0' for no timeout.

'DISPLAY ALL PARTS ON SOURCING SCREEN'

If enabled, all parts on the sales order display in the upper grid on the ADVANCED SOURCING screen regardless of the modifier used or whether or not sourcing is needed. If disabled, then only parts sold using the 'BUYOUT' or 'DROPSHIP' modifiers display in the upper grid.

System Setups:

'USE SOURCING COST AS POS COST'

If enabled, the part and core cost from the supplier is used for the part and core cost on the sourced order and on the purchase order for both sourced and auto sourced orders. If not, the regular part and core cost are tracked.

Note: If both 'USE SOURCING COST AS POS COST' and 'UPDATE POS COST WITH AVG COST DURING FINALIZE' settings are enabled, and the part’s average cost is not equal to zero, Average Cost is used as the 'POS COST' once the invoice is finalized.

'REQUIRE FINISH FOR SOURCED ITEMS'

If enabled, the 'FINISH' button must be clicked before exiting a sales order with at least one item that has been sourced. Click 'FINISH' to place the order or click 'ON ACCT' or 'PAY NOW' to finalize the order if the 'ALLOW AUTO PROCESS COMMERCIAL ACCOUNTS' or 'ALLOW AUTO PROCESS RETAIL ACCOUNTS' settings are also enabled.

If disabled, the 'FINISH', 'ON ACCT/PAY NOW', 'INVOICE/SLIP', or 'CANCEL ORDER', 'QUOTE', 'PICK', 'PACK', or 'WIP / HOLD' buttons can be clicked, whether or not items with insufficient sell quantity have been sourced.

'PROMPT FOR FULL PACKS'

If enabled, and the 'USE BUY QTY RULE' setting is enabled for the supplier, the sourced sell quantity must be in full pack increments when ordering from the Primary DC.

If disabled, any quantity can be ordered. The 'AUTOSOURCE' process does not discard any quantity in excess of the customer sell quantity and, instead, depending on an application switch, any excess quantity is added to stock or to a return manifest.

'TRANSFER SOURCED ORDER'

Multi-store setup: Select whether orders received from a transfer account print as an 'INVOICE', 'PICK', or 'PACK'. If set to 'DEFAULT', the value of the customer 'PROCESS RCVD ORDER' setting is used.

SOURCE IT Button

Clicking the 'SOURCE IT' Button:

-

Displays the 'INSUFFICIENT QUANTITY - SOURCING' window when the 'USE QUICK SOURCING' control is enabled, there is only one item to be sourced and it is unreserved.

-

Displays the ADVANCED SOURCING screen when the 'USE QUICK SOURCING' control is disabled, there is only one item to be sourced whether it is reserved or not.

-

Displays the ADVANCED SOURCING screen when there is more than a single item to be sourced.

-

Displays the ADVANCED SOURCING screen if Vision or Worldpac is enabled.

Enter the quantity of the part to be transferred and click the 'XFER' button to complete the transfer.

Multi-Store/TRANSFER Button

Click the 'TRANSFER' button to open a window used to 'TRANSFER PARTS' from one store to another instead of sourcing when quantities are needed for the part being sold.

The window displays each store, any 'OVRSTK' (overstocked quantity), the 'QTY AVL' (quantity available), the 'MIN', 'ON ORD' (on order quantity), 'INB QTY' (inbound quantity), the 'PER CAR', and 'CURRENT', 'YTD' (year-to-date), 'LYTD' (last year-to-date) and the 'CLASS' code and the last 12 months’ part histories to date.

The 'TRANSFER PARTS POPUP' User Security proc determines whether or not the 'TRANSFER' button is available to the logged in employee.

If the 'OVRSTK' (overstock) quantity is calculated based on the stocking level ('MIN', 'MAX', or 'ORDER POINT') set up in 'STOCKING LEVEL' control. If the 'AVL QTY' minus the stocking level is positive, it displays in a red font. If negative, it displays in a black font.

Enter the 'FROM' and 'TO' store locations and the 'XFER QTY' (transfer quantity), and click the 'XFER' button to complete the transfer.

A prompt opens with the transfer order number. Click 'OK' to continue.