Stock ASPM Mix Order

About Mix Orders

There are two types of mix orders: 'Stock Forecast Mix Order' and 'Stock ASPM Mix Order'. These order types combine a stocking-level order with a sales history order so that the quantities ordered for parts are determined by the higher calculated value between the two methods used. When a mix order is run, the system generates a purchase order using the default stocking level order method and then runs the same order using a sales history method (Forecast or ASPM). Depending on the configuration, the higher quantities will be used.

For example: if a part has 0 'QTY AVAILABLE' and an 'ORDER POINT' of '5', when an 'Order to Order Point' method is used, the system will order a quantity of 5 for the part. However, if the part is popular, and sales based on historical data determine that an average of 8 parts were sold within the designated period, 8 parts would be ordered if only a sales-based method is used. With a mix method, both purchase orders are compared and the one with the higher quantity for the part is the one which will be ordered. In this example, 8 parts would be on the mix order.

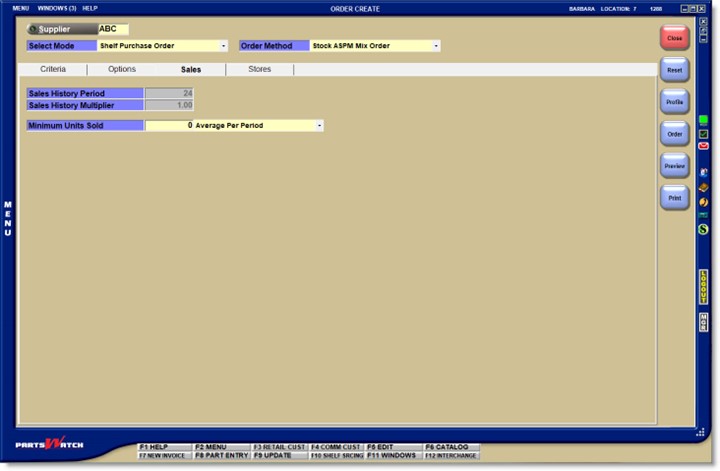

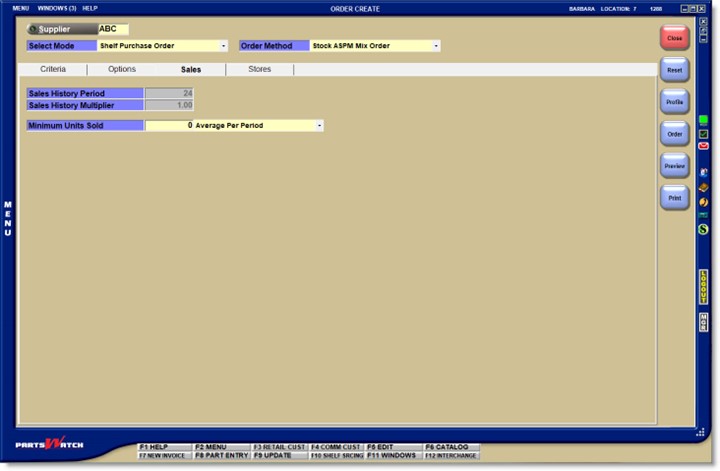

Select Mode: Shelf Purchase Order

Order Method: Stock ASPM Mix Order

"Average Sales Per Month" (ASPM) refers to the average number of units sold (less returns and UNDOs) for a part within a fiscal or calendar monthly period.

Note: The average number of units sold number is typically fractional (e.g. 2.3 or 4.7) and standard rounding rules are used to calculate a part's order or return order quantity (i.e. 2.3 would round to 2 and 4.7 would round to 5).

Order quantities are based on the higher of a stocking level calculation (Min, Max, or Order Point over quantity available), or a sales calculation (weighted average sales per month over quantity available). This 'Order Method' combines an ASPM Order with one of the five stocking level methods (e.g. 'Order to Min', 'Order to Max', 'Order Min to Max', 'Order Average Min Max', 'Order to Order Point').

Note: This type of order allows order quantities to be "boosted" above the stocking level based upon high volume sales.

The 'Sales' tab displays when 'Stock ASPM Mix Order' is selected from the 'Order Method' drop-down.

Optionally click the 'Criteria' tab and select or edit the Line Codes purchased under the Supplier and/or set up the filters used to narrow the parts that will be considered for the order.

Optionally click the 'Options' tab and enable/disable the predefined conditions that further refine and filter the parts that will be considered for the order.

Note: For any "Mix" order method, some options will only apply to one method and some to both. For example, the option 'Ignore On Order Values' would apply to both a Stock order and an ASPM order, but the option 'Increase Order Quantity To Per Car' only applies to an ASPM order.

Available Default/Override (left-side) filters are:

Note: The system-level 'STOCK LEVEL' is used as the stocking level default method. Click the 'Mix Order Stock Level' override to change the stocking level used for the order.

Additional (right-side) filters are:

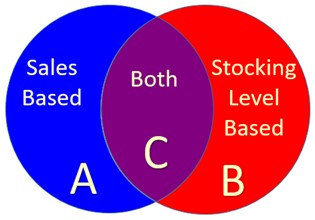

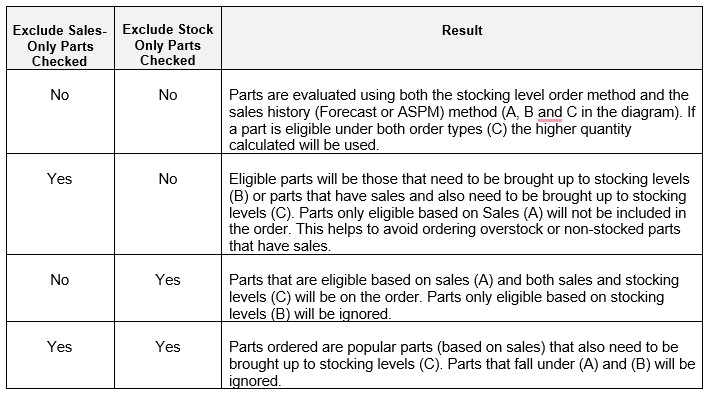

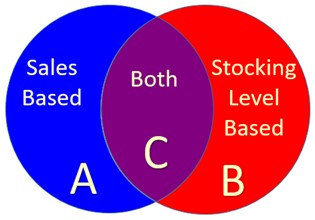

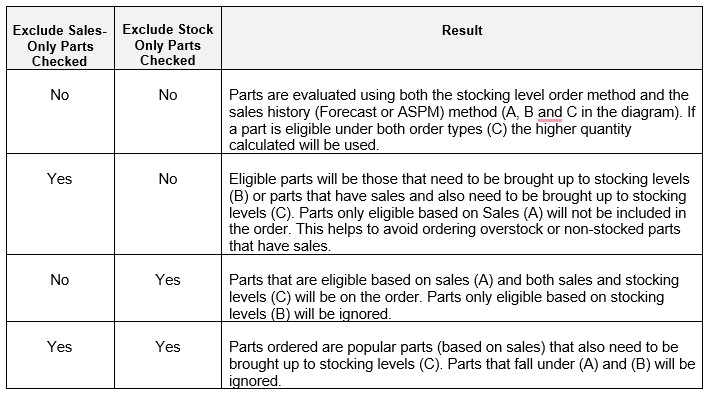

Note: The 'Exclude Sales Only Parts' and 'Exclude Stock Only Parts' options are available for Mix orders only and provide additional control to determine which parts appear on the order. Refer to the About Mix Orders help for additional information.

Two controls on the 'Options' tab are available for "Mix" 'Order Methods' only and both default to disabled:

- 'Exclude Sales Only Parts'

- 'Exclude Stock Only Parts'

The purpose of these two options is to provide additional control to determine which parts appear on the order. This is helpful because a "mix" method prepares two "temporary" orders using two different 'Order Methods' and then compares and combines the results into one order.

- If all parts should be included on the order whether there is a "need to order" based upon a stocking level or based upon sales, then leave the default of unchecked for both options.

- If the "Stocking" method used should be the primary method, check the 'Exclude Sales Only Parts' option, and leave the 'Exclude Stock Only Parts' option unchecked. This setting combination will avoid ordering "overstock" or "non-stocked" parts that have sales.

Optionally click the 'Stores' tab and select the stores for multi-store orders.

From the 'Sales' tab, select the histories the same way as defined for the 'Order Method' of 'ASPM Order'.

When ready, optionally click the 'Preview' or 'Print' button to output a report with all parts that will be on the order, or click the 'Order' button to generate the order.

Click the Order button and:

If the value of 'Mix Order Stock Level' is not a "stocking-level" order method (e.g. 'Order to Min', 'Order to Max', 'Order Min to Max', 'Order Average Min Max', 'Order to Order Point'), display a pop-up with text indicating that selection is required and 'OK' button.

Calculate all part order quantities based on the following formula:

1st: Part order quantities are determined using the stocking level calculation using the 'Mix Order Stock Level' selected (e.g. 'Order to Min', 'Order to Max', 'Order Min to Max', 'Order Average Min Max', 'Order to Order Point').

2nd: Part order quantities are determined using the ASPM 'Order Method'.

3rd: All order quantities from each order method are compared per part and the higher of the two values on the order are used.

- For example, if a part's 'QTY AVAILABLE' is '2', using the 'Mix Order Stock Level' of 'Order to Max':

- The part's 'MAX' is '4', and the calculated order quantity will be 2 (4 - 2).

- If the part has "weighted" average sales of 3 for the sales history period, then the calculated order quantity will be 1 (3 - 2) using the ASPM 'Order Method'.

- Comparing both results, the part's order quantity on the order will be set to 2, the higher of the two values.

- For a second example, if a part's 'QTY AVAILABLE' is '2', using the 'Mix Order Stock Level' of 'Order to Max':

- The part's 'MAX' is '4', then the calculated order quantity would again be 2 (4 - 2).

- If the part has "weighted" average sales of 5 for the sales history period, then the calculated order quantity would be 3 (5 - 2), using the ASPM 'Order Method'.

- Comparing both results, the part’s order quantity will be set to 3, the higher of the two values.

- For a third example, if the part's 'QTY AVAILABLE' is '4', using the 'Mix Order Stock Level' of 'Order to Max':

- The part's MAX is '4', then the calculated order quantity will be 0 (4 - 4). A zero-value order quantity would exclude the part from the order, based upon stocking need, but the order must still evaluate a need based on sales.

- If the part has average sales of 3 for the sales history period, and a 'Sales History Multiplier' of '2' then the weighted average sales would be 6 (3 * 2), and the calculated order quantity would be 2 (6 - 4); using the ASPM 'Order Method'.

- The order quantity will be set to 2, but only if the 'Exclude Sales Only Parts' option is unchecked because this part only has a need-to-order based upon sales.

- If the 'Exclude Sales Only Parts' option is checked, the part will be excluded from the order.

- If the same part had a 'Sales History Multiplier' of '1.00' (instead of '2.00'), then the part's weighted average sales would be 3 (3 * 1), and the calculated order quantity would be -1 (3 - 4), using the ASPM 'Order Method'. A negative order quantity would exclude the part from the order based on the sales need.

- Therefore, the order would exclude the part because there is no need based upon either stocking level or sales; regardless of the setting of both ‘Exclude Sales Only Parts’ option.

4th: Parts are excluded from the order that only have an order quantity needed using the ASPM 'Order Method' if the 'Exclude Sales Only Parts' option is checked. If the option is unchecked (default value) then these parts are included in the order.

Note: Checking the 'Exclude Sales Only Parts' option is a way to "boost" order quantities based upon sales for "understocked" parts without also including "overstocked" or "non-stocked" parts on the order that had sales during the sales history period.

5th: Parts are excluded from the order that only have an order quantity needed using the 'Mix Order Stock Level' if the option 'Exclude Stock Only Parts' option is checked. If the option is unchecked, then these parts are included in the order.

Note: Unchecking the 'Exclude Stock Only Parts' option is a way to always include ordering "understocked" parts regardless of whether they had sales during the sales history period.