Supplier Order

The SUPPLIER ORDER SPECIFICS screen is used to set up and maintain the parameters needed for purchasing and returning products to suppliers.

Menu Path: Vendor, Vendor/Supplier, Supplier Order, SUPPLIER ORDER SPECIFICS screen

Edit a Supplier

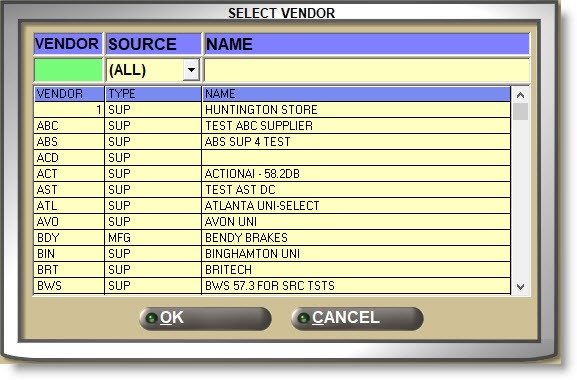

Enter a Supplier Code in the 'SUPPLIER' field or click the 'SUPPLIER' button to open the 'BROWSE SUPPLIERS' window to search for a supplier.

Suppliers cannot be added from this screen and if one is entered that does not exist, the system prompts to add Suppliers from the SUPPLIER ENTRY screen.

Optionally edit the:

- 'TYPE'

- 'NAME'

- 'DESCRIPTION'

Optionally enter whether the Supplier is the "primary" vendor the parts are normally purchased from or a "secondary" vendor.

If the 'Designation' filter on the ORDER CREATE screen is used to filter the parts considered for the order and at the time of order creation, if the ORDER CREATE 'Designation' filter is set to:

- 'PRIMARY' - The system considers all parts with the part 'Vendor Information' settings set to 'PRIMARY'.

- 'SECONDARY' - The system considers all parts with the part 'Vendor Information' settings set to 'SECONDARY'.

- 'ALL PARTS' - The system looks at the Supplier 'VENDOR' setting and if it is set to:

-

'PRIMARY' - The system considers all parts with the 'Vendor Information' settings set to 'PRIMARY'.

-

'SECONDARY' - The system considers all parts with the 'Vendor Information' settings set to 'SECONDARY'

-

'NOT SELECTED' - The system considers all parts for the order.

-

Determines how items not shipped on a stock order should be handled:

- 'CANCEL' - The Supplier does not fill backorders and all items not received should be canceled from the purchase order.

- 'BACKORDER' - The Supplier will ship items not received when possible and all items not received will be added to a backorder purchase order until received.

Determines whether or not all lines are ordered.

- Checked - The 'ALL LINES' flag on the SUPPLIER LINE CODES screen is checked also and all lines are considered in purchase orders.

- Unchecked - The 'ALL LINES' flag on the SUPPLIER LINE CODES screen is unchecked also and only the designated lines are considered in purchase orders.

Determines the record retention for open purchase orders for this supplier for this store.

Determines whether or not the CURRENCY EXCHANGE setup is used to calculate the cost on Purchase Orders to the vendor.

- Checked - Currency exchange is used for PO receipt.

- Unchecked - Currency exchange is not used for PO receipt.

Select the process that will be followed for SORO:

- 'SUPERSEDE INFO ONLY' - A supersede notice sent on an ASN is notification only and updates invoice and catalog view/notification only.

- 'IGNORE' - The supersede notification is ignored. However, ASNs for sourced and shelf orders for the vendor are still received.

Determines the type of multi-store orders created. When one of these sales orders is printed as an invoice (whether automatically when transfer account is set to create orders as 'INVOICE') or manually, an ASN is applied to the corresponding PO in the secondary stores.

- 'USE STORE DEFAULT' - Uses the PO type setting in the 'MULTISTORE PO TYPE' field from the STORE GENERAL SETUP screen, 'PURCHASING' tab unless overridden in the ORDER CREATE screen.

- 'CONSOLIDATED' - Other stores are considered when calculating order quantities. Only the ordering store has a PO with a consolidated order quantity. All stock is received into the ordering store that created the order and that store will send the stock to the other stores.

- 'DISTRIBUTED' - Other stores are considered when calculating order quantities. When 'PLACE ORDER' is clicked, purchase orders are created in each store that had a part on the original PO. When the order in the primary store is received, transfer sales orders are automatically generated in the primary store to transfer stock to other stores (therefore, the stock received for these stores is allocated to the sales orders rather than increasing QOH in the primary store). These sales orders may be edited in the primary store if the transfer account is set to create orders as 'PICK' or 'PACK'.

- 'CONSECUTIVE' - For consecutive multi-store purchase orders.

ORDERS DUE ON

Enter the day of the week that an order for the vendor is due on. For example, purchase orders for this line may be ordered on Tuesdays, therefore they may be due on Wednesdays.

DELIVERY DAYS

Enter a value from '1' – '999' that is used to determine when an order is expected.

Unless a date is included in the communication from the vendor, the system uses the value of this field to determine how many days it takes to receive a shipment once the order is transmitted. The calculated date displays in the 'SHIP/DUE' column on the MAIN PURCHASE ORDER SELECTION screen.

VENDOR ACCT #

Optionally enter up to 12 alphanumeric and special characters for the vendor number assigned to the Supplier.

ASN SUPPLIED BY VENDOR

Determines whether or not the vendor sends and Advance Shipping Notice (ASN) for transmitted orders.

- Checked - ASNs are sent by the vendor.

- Unchecked - ASNs are not sent by the vendor.

ALLOW ASN SET STOCKING DETAILS

Determines whether or not updates are permitted to the stocking levels in the part table by ASN communications from the vendor that brings changes.

- Checked - Stocking level changes are allowed.

- Unchecked - Stocking level changes are not allowed.

ALLOW EDIT NID PO

Determines whether or not New Item Distribution (NID) purchase orders can be edited or deleted before being received. NID orders are normally sent by the supplier warehouse with new items to stock and are not ordered by the store.

- Checked - NID orders can be edited and deleted.

- Unchecked - NID orders cannot be edited or deleted.

Determines whether or not manifests are transmitted when closed.

- Checked - The 'CLOSE / TRANSMIT' button is available at the bottom of the RETURN MANIFEST DETAIL screen and if clicked for a finalized manifest, the application will prompt to transmit the manifest to the vendor.

- Unchecked - The 'CLOSE' button is available is available at the bottom of the RETURN MANIFEST DETAIL screen and if clicked, the system will prompt to close the manifest without transmitting it to the vendor.

Determines whether or not purchase orders can be created for the supplier.

- Checked - If checked, purchase orders cannot be created for the supplier. When the 'Order' button is clicked to create a purchase order for a "blocked" supplier, a pop-up displays informing “This Supplier is blocked from new purchase orders.”

Stock inquiries will not be sent from the 'Quick Sourcing' pop-up, or the ADVANCED SOURCING or SHELF SOURCING screens.

The STORE SOURCE SETUP screen displays the 'SOURCE NAME', 'VENDOR', and 'RULE' in the color red as an alert that the source is "blocked" and must be changed because sourced orders cannot be created for this supplier.

The 'BLOCK ON PO' column on the SUPPLIER LIST REPORT displays 'Y' for blocked suppliers and is blank for active suppliers.

Note: After checking the 'BLOCK FROM PO' setting for this supplier, review current open purchase orders and if any are found with the status of 'NEW', 'WIP', or 'FIN', manually delete them. - Unchecked (default) - The selected supplier is not blocked from order creation.

Enter the amount or the percent that is used to calculate the cost of the freight per part and per core on shelf purchase orders only. This value is not used for sourced orders or for overstock or manifest return orders.

Enter the amount or the percent that is used to calculate the cost of the duty per part and per core on shelf purchase orders only. This value is not used for sourced orders or for overstock or manifest return orders.

Sourcing Setups

Depending on the Supplier in focus, the setup displays as two separate fields or a single field:

If a 'SHIP METHOD' / 'SHIPPER #' is set up on the STORE SOURCE SETUP screen for the vendor, the control will display as a 'SHIP METHOD' drop-down list and a 'SHIPPER #' button.

Click the drop-down field and select the sourcing 'SHIP METHOD' for the Supplier.

Click the 'SHIPPER #' button to open the 'BROWSE SHIPPER #S' window to select the best type of shipping for the selected 'SHIP METHOD'.

If a 'SHIP METHOD / SHIPPER #' setup is saved as a 'VENDOR SOURCE SETUP' for the 'VENDOR', the control will display as a single field with a drop-down list to select from.

Click the drop-down field and select the sourcing 'SHIP METHOD / SHIPPER #' for the Supplier.

Note: The control overrides the 'DEFAULT SHIP METHOD' field in the STORE GENERAL SETUP screen, for SHELF SOURCING orders.

Click the drop-down field and select the price level used for sourcing from this vendor.

- If a price level is selected, the 'EACH' price of parts sourced at Point-of-Sale will be recalculated using this sell level. If the price level has a value of '0.00', regular Point-of-Sale pricing calculations will be followed.

- If set to 'NOT SELECTED', regular Point-of-Sale pricing calculations will be followed.

Note: If a price level is selected, the 'SOURCING SELL + OR – PERCENT' setting will be applied regardless of any other customer PRICE PLAN SETUPs.

Enter a markup as a positive value or a discount with a minus (-) that will be applied to the 'SOURCING SELL LEVEL' if one is set up to calculate pricing for parts sourced from this vendor.

Click the drop-down field and select how Point-of-Sale handles returns of resalable items that were sold with the 'BO (BUYOUT)' and 'DS (DROPSHIP)' modifiers.

Note: If the 'SOURCE TYPE' of the vendor that Buyout and Dropship items were sourced from is either a 'STORE' or a 'SUPPLIER', the value of the 'SOURCED RETURN DESTINATION' is used to determine how resalable sourced returns are handled.

If the 'SOURCE TYPE' is a 'LINE CODE', all Buyout and Dropship returns go to the shelf. If more control of where returns for items sourced from a Line Code are returned to is needed, a supplier code for the specific Line Codes can be set up.

- 'PROMPT' - Buyout And Dropship resalable returns sourced from a supplier (including ^!^) opens a prompt at Point-of-Sale with the choice to put the item on the shelf or on a manifest.

- 'SHELF' (default) - Resalable sourced Buyout and Dropship returns are automatically added back to the shelf and the 'QTY AVAILABLE' is increased.

- 'MANIFEST' - Resalable sourced Buyout and Dropship returns are automatically added to a return Manifest.

Regardless of the setting, additional pop-ups may be displayed.

SOURCED RETURN APPLY RESTOCKING FEE

Determines whether restocking fees are charged when returning sourced parts. For example, restocking fees may be applied to items sourced from outside vendors but not from company-owned warehouses or sister stores.

Note: Restocking fees only apply when set up under the store 'FEES AND MARGINS' tab.

- Checked - Restocking fees, if set up, are applied.

- Unchecked - Restocking fees, whether set up or not, are not applied.

SOURCING COST LEVEL

Click the drop-down field and select the price level that will be used as 'COST' for sourced orders created for this supplier.

If the field is set to 'NOT SELECTED' then 'CURRENT COST' will be used as 'COST' for sourced orders created for this supplier.

SOURCING + OR - PERCENT

Used to change the cost tracked for sourcing. Works in conjunction with the 'SOURCING COST LEVEL' field.

Enter a markup as a positive value or a discount with a minus (-) that will be applied to the 'SOURCING COST LEVEL' if one is set up to calculate the cost for parts sourced from this vendor.

USE SUPPLIER COST FOR SRCD ORDERS

Determines the 'COST' to be used for sourced orders.

- Checked: Uses the cost sent by the supplier for sourced orders. If a cost is not provided, then the 'SOURCING COST LEVEL' is used if available, or the part 'COST' if not.

- Unchecked: Does not use the supplier cost if sent during sourcing and uses the 'SOURCING COST LEVEL' if available, or the part 'COST' if not.

SOURCED NOT SHIPPED POLICY

Click the drop-down field and select the method used for customer and shelf-sourced order transmission via ACONNEX that is sent to tell the vendor whether they should back order or cancel any items not available.

- 'CANCEL' - Items that are not available to fill the sourced ordered quantity are canceled and not sent when available.

- 'BACKORDER' - Items that are not available to fill the sourced order quantity are put on backorder and sent when available.

Available Sourcing Modifiers / Default

Determines the modifiers that are allowed at Point-of-Sale for items that are not available and must be sourced.

Checked - The modifier will be available to sell parts with insufficient quantity.

- (BO) BUYOUT

- (DS) DROPSHIP

- (XF) TRANSFER

Default: Check the single modifier that will normally be used when sourcing parts with insufficient quantity. The default can be edited at the time of the sale.

Unchecked - The modifier will not be available.

PO PART COST LEVEL

Click the drop-down field and select the price level that will be used as 'COST' for purchase orders created for this supplier.

If the field is set to 'NOT SELECTED' then 'CURRENT COST' will be used as 'COST' for purchase orders created for this supplier.

RTN FULL PACKS ONLY

Determines whether or not parts purchased in full packs must be returned to the vendor in full packs.

- Checked: Parts purchased in full pack quantities must be returned in full packs.

- Unchecked: Parts can be returned in full for any partial pack quantities.

USE BUY QTY RULE

Used to determine whether or not parts must be ordered in multiples of the 'BUY QUANTITY RULE' when creating any type of Purchase Order if the 'USE BUY QTY RULE' is enabled for the supplier.

- Checked: The 'BUY QUANTITY RULE' is used when creating purchase orders forcing orders to be created in increments of the rule.

- Unchecked: The 'BUY QUANTITY RULE' is ignored when creating purchase orders, allowing any increment to be ordered.

Used to determine whether or not orders can be edited after transmission.

- Checked: If needed, purchase orders can be opened in the PURCHASE ORDER detail screen and edited after they are transmitted; however, orders are locked and not editable if queued for transmission but not yet sent.

Return orders opened in the RETURN PURCHASE ORDER DETAIL screen can be edited, however, edits will not be reflected for historical manifests. - Unchecked: Once transmitted, editing is not allowed.

The Minimum Thresholds are displayed on the PURCHASE ORDER detail and/or the PO INFO screens and are used as an alert during purchase order edit when the supplier’s minimums are not met.

If the 'TOTAL' is less than the 'MINIMUM', the 'TOTAL' field displays in bright orange so that the order can optionally be edited to meet the minimum.

Purchase Order Detail

Purchase Order Info

Enter a value from '1' to '999999999' as the least dollar amount that the supplier requires for stock purchase orders. The system uses the part 'COST' used to create the order to calculate the "minimum". A decimal place is not needed since the value is not whole dollars only.

MINIMUM UNITS

Enter a value from '1' to '999999' as the least quantity or number of units (as opposed to the number of different parts) that the supplier requires for stock purchase orders.

MINIMUM PACKS

Enter a value from '1' to '999999' as the least number of packs that can be ordered. The Buy Quantity Rules are used if set up and if not, each part is considered a single pack.

MINIMUM WEIGHT

Enter a value from '1' to '999999' as the least weight of the entire order that the supplier requires for stock purchase orders.

The system uses the 'WEIGHT' field on the MAIN PART ENTRY screen to determine the total weight of the order. Even though the 'WEIGHT' is stored in 3 decimal places per part, the system rounds the total weight on the order.

MINIMUM VOLUME

Enter a value from '1' to '999999999' as the least liquid volume for suppliers that sell liquids such as oils, paints, and chemicals.

The system uses the 'VOLUME' field on the ORDER - COST screen to determine the total volume of the order.

COST EXCH RATE

Enter an alternate currency cost used as a 'MINIMUM COST' threshold when buying from a supplier in the same or a different country or who sells merchandise with cost thresholds in another currency other than the store’s local currency. The field defaults to '1.0000' and supports four decimal places.

At the time of ORDER CREATE, the 'DEFAULT' minimums can be edited in the 'OVERRIDE' column if needed.

During ORDER CREATE, if used, the system multiplies the value to the total part cost (include core cost if the setting 'INC CORE IN MIN COST' is enabled, before applying the 'MINIMUM COST' threshold rule to the 'TOTAL EXCH COST' instead of 'TOTAL COST'.

Note: This enables applying a different currency exchange rate for any supplier in any country for any order created. Since currency exchange rates can change on a daily basis, if there is a delay in transmitting the order, the minimum threshold calculated at order creation may no longer be accurate.

INCLUDE CORE IN MIN COST

Determines whether the core cost is included with the part cost to calculate the 'TOTAL COST' used to compare to the 'MINIMUM COST' threshold during PO creation.

- Checked - Core cost plus the part cost is used to calculate the PO’s 'TOTAL COST'.

- Unchecked - Only part cost is used to calculate the PO’s 'TOTAL COST'.

CREATE ORDER BELOW MIN

Determines whether or not purchase orders that fall below the 'MINIMUM' thresholds can be created or not.

- Checked - Orders are created regardless of the 'MINIMUM' thresholds.

- Unchecked- Orders are created only if the total value, e.g., cost, units, packs, weight, or volume are equal to or greater than the corresponding default 'MINIMUM' threshold amount set up for the supplier.

FORECAST % LESS THAN MIN COST

Enter a value between '1' and '20' as the percentage applicable to new purchase orders created using the 'Forecast Order' 'Order Method' when there is also a 'MINIMUM COST' threshold set up for the supplier.

Note: This percentage is ignored during order creation if there is no vendor minimum cost threshold or if the 'Order Method' is not 'Forecast Order'.

This percentage determines how close to the vendor’s minimum cost threshold amount the purchase order’s 'TOTAL COST' must be before the system will automatically start to incrementally increase the order’s 'TOTAL COST' until the vendor’s minimum cost is met.

Used to set up discounts given by the supplier for any reason, such as product sales that are run for a set time.

PO + OR - PERCENT

Enter a value up to '99.999' with a minus (-) as a discount or as a markup, as a positive number that will be applied to a purchase order to calculate the cost.

START / END DATE

The date fields default to no start or end date. Check a field for the current date or select a starting and ending date during which the 'PO + OR – PERCENT' will apply.

Note: The setting applies to ORDER CREATE purchase orders only and does not apply to Shelf or Customer-sourced orders.

Auto Post functionality allows automatic purchase order post when an ASN is applied to a PO, without user intervention, by order type:

- 'AUTO SOURCED PO' - Customer-sourced orders where the invoice is finalized before the order is received.

- 'SOURCED PO' - Customer-sourced orders where the invoice remains open until the PO is received.

- 'SHELF SOURCED PO' - Orders created using SHELF SOURCING.

- 'NON-SOURCED-PO' - Orders created in ORDER CREATE including 'SHELF', 'TRANSFER', 'STOCK ADJUST', 'DEAL', and 'NID' (New Item Distribution).

Note: Auto post functionality is only used when the 'ASN SUPPLIED BY VENDOR' flag is checked.

Click the drop-down field and select how automatic order receipt is handled per order type:

- 'F' (full) - Orders are not automatically received until the total 'ON ORDER' quantities are shipped. An ASN with partial order quantities will not cause the quantities to go on backorder and instead, the order will not be auto-received until subsequent ASN(s) complete the full ordered quantities. At that time, the full order is automatically received into stock.

- 'P' (partial) - The 'INBOUND' quantities from ASNs will be automatically received into stock regardless of the 'ON ORDER' quantities. Any quantities not 'INBOUND' will be put on back order and automatically received as subsequent ASN(s) arrive.

- 'N' (none) - Purchase Orders are not automatically received and must be manually received.

Determines whether or not return orders are automatically closed and the return quantities removed from stock for transmitted return orders. RETURN orders include: 'OVERSTOCK', 'PDC', 'RECALL', and 'STOCK ADJUST RETURN'.

- Checked - Return orders will be automatically removed from stock and the orders closed, regardless of whether return orders are manually transmitted from the RETURN PURCHASE ORDER screen or automatically transmitted from the TIMED ORDERS QUEUE.

Return orders do not automatically print when closed and do not appear in the list of open orders in the MAIN PURCHASE ORDER SELECTION screen. The orders must be printed before transmitting or historically from the PATI REPORTS screen. - Unchecked: Return orders must be manually closed and return quantities removed from stock using the RETURN PURCHASE ORDER detail screen functionality.

Determines how to handle ASNs that arrive for purchase orders that have already been closed.

Click the drop-down field and select:

- 'System Default' - Uses the value of the 'ASN Process for Closed PO' system setting to determine how to handle the ASNs for closed or deleted POs.

- 'Reopen PO' - Closed or deleted purchase orders are reopened or recreated and the ASN is applied.

- 'Reject ASN' - ASNs are ignored and closed or deleted purchase orders are not reopened or recreated.

- 'Create NID PO' - New NID purchase orders are created and the ASNs are applied to them instead of reopening or recreating the original purchase orders.

- 'Reopen PO by ASN'

-

When ASNs arrive for canceled/deleted single or multi-store consolidated purchase orders:

-

The purchase orders are reopened with the list of parts on the ASN that is also on the PO and that also exist in the store’s inventory.

-

The "on order" quantity for the line items on the PO is set to the ship quantity of the ASN.

-

The system applies reverse 'Buy Quantity Rule' logic to the ASN ship quantity.

-

Any parts on the ASN that do not already exist on the PO and/or do not exist in the store’s inventory are not placed on the resurrected PO.

-

-

When ASNs come in for canceled/deleted multi-store distributed purchase orders:

-

The application reverts to the functionality of the option 'Reopen PO' and will not resurrect the PO with a subset of line items of only those parts listed on the ASN. The new "Reopen PO by ASN" feature is not supported with multi-store distributed orders.

-

-

Note: If the control is set to reopen/recreate purchase orders, any purchase order will be opened regardless of whether any or all of its ordered quantities have already been 100% fulfilled previously.

Note: If the supplier sends additional parts on an ASN, (by accident or on purpose) they will be added to the purchase order. The stores will be able to receive the additional parts or resolve any receiving discrepancies with the supplier.

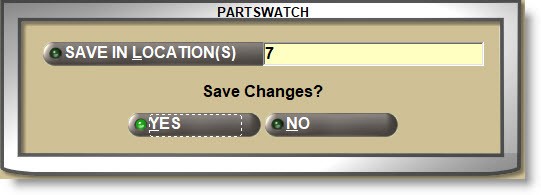

When changes are made to a field and 'UPD' is clicked, or 'CLOSE', 'PREV', or 'NEXT' is clicked without first clicking 'UPD', the 'SAVE CHANGES' pop-up displays.

For multi-stores: Clicking the 'UPD' button opens a pop-up to select the locations to save the changes depending on employee setups:

- The 'ALLOW SAVE LINE INFO IN MULTIPLE LOCATIONS' User Security proc must be enabled for editing.

- The settings on the EMPLOYEE SETUP screen allow access to more than one location.

The pop-up defaults to the current location. Click the 'SAVE IN LOCATIONS' button to open the multi-select 'BROWSE LOCATIONS' window and check, one, multiple, or all locations. Answer 'YES' to save the changes to the selected locations.