Order/Cost

The ORDER - COST screen is used to add and maintain all inventoried part numbers by manufacturer Line Code that are used by the Invoicing, Purchasing, and Reporting modules.

Menu Path: Inventory, Part Entry, Order / Cost, ORDER - COST screen

Like most PartsWatch maintenance screens, the 'EDIT' and 'UPD' (update) buttons must be used when changes are made. 'EDIT' must be "off" when entering a part number and "on" when changing the part settings. 'UPD' must be clicked to save the changes.

Therefore, to edit parts using the ‘F’ hot keys:

- (EDIT off) Enter a part number and press 'F5' (EDIT on)

- Make changes and press 'F9' (changes saved)

- Press 'F5' (EDIT off) and find another part

- Press 'F5' (EDIT on) and make changes

- Press 'F9' (changes saved)

If changes are not saved, pressing the 'F5' key, clicking the 'EDIT' button, or closing the screen, a prompt opens to save the changes.

Enter 1-3 alphanumeric characters that represent a valid Line Code in PartsWatch.

- If the value entered is not a valid Line Code, pressing the 'Enter' key moves the cursor to the 'P/N' field, however, without a part number, the system opens a pop-up stating that the line code is not found.

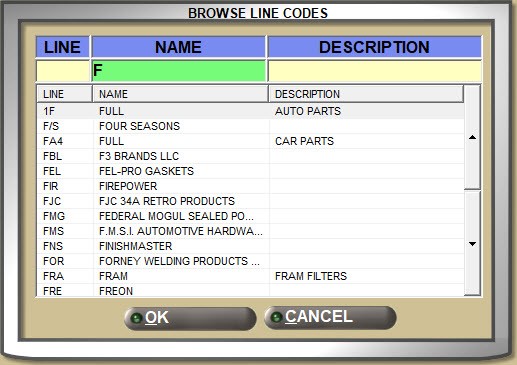

- Click the 'LINE' button to open the 'BROWSE LINE CODES' pop-up to search for a Line Code. Type-ahead functionality can be used to find a Line Code by 'LINE' code, line 'NAME', or 'DESCRIPTION'.

With a 'LINE' displayed:

- Press the 'Enter' key at the 'P/N' field and the first part number from the part table in the Line Code 'SORT CODE' order displays with the part field attributes.

- Enter a valid Part Number in the 'P/N' field and press the 'Enter' key to display the part field attributes for that part.

- The system checks for "stripped" part numbers where letters (A through Z) and numbers (0 through 9) are valid and all other characters are ignored for a part number search.

- If the part number is not found, the system prompts to add it.

Answer 'Yes' and the part is added.

Answer 'No' and the 'P/N' field clears.

Without a 'LINE' displayed:

- Enter a Part Number and if a single match is found, it will display.

- If more than a single match is found, the Available Matches window opens with all Line Codes that contain the entered part number. Select the correct one to display that Line and Part Number.

- If a match is not found, the cursor remains in the 'P/N' field waiting for valid input.

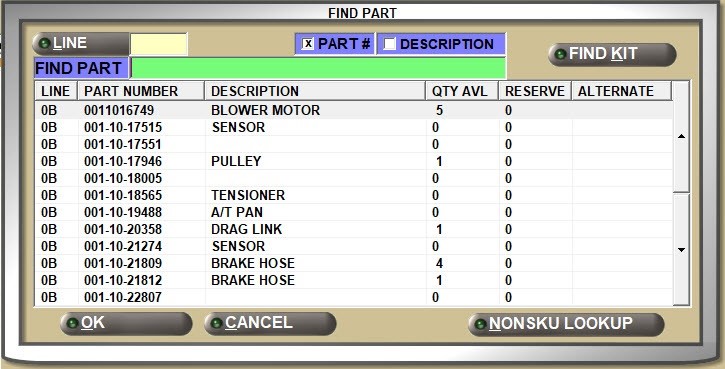

Click the 'P/N' button to open the 'FIND PART' window to search for a Part Number with or without a Line Code entered in the 'LINE' field.

Enter up to 255 alphanumeric and special characters that describe the part in focus.

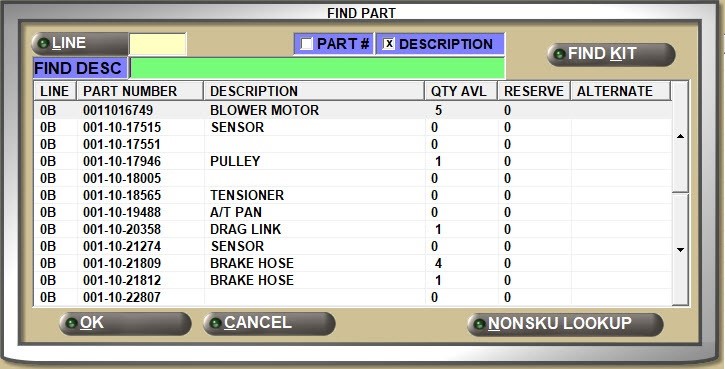

Click the 'DESCRIPTION 1' button to open the 'FIND PART' window to search for parts by description. Focus is on the 'FIND DESC' field in the pop-up.

Enter up to 255 alphanumeric and special characters that describe the part in focus with an additional description that, depending on the process, can be used with or instead of 'DESCRIPTION 1'.

The 'DESCRIPTION 2' button is not enabled for a search, and instead, click the 'DESCRIPTION 1' button to locate a part from the 'FIND PART' window by description.

Stock Quantities

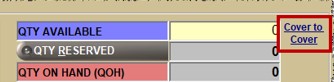

Displays the number of units that are on the shelf and available for sales for the part. The field is updated by Point-of-Sale and Purchasing, as well as manually editable.

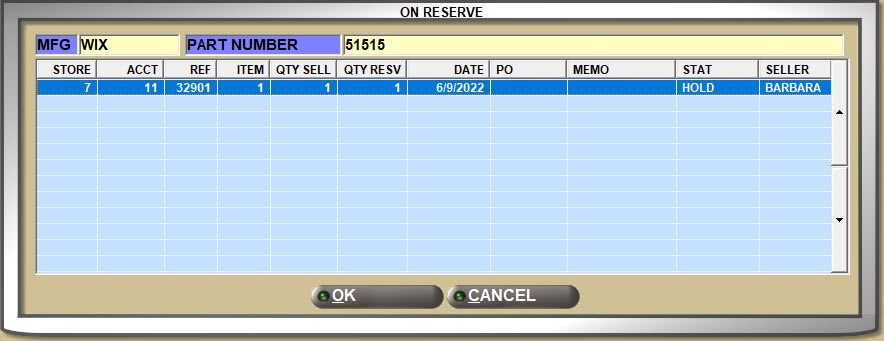

Displays the number of units that are "on reserve" on open sales orders for the part, for information only.

If the quantity is on reserve, click the 'QTY RESERVED' button to open the 'ON RESERVE' window with the accounts and sales order reference numbers that the part in focus is on.

Displays the total number of parts currently in stock whether on the shelf or on an open sales order. ('QTY AVAILABLE' + 'QTY RESERVED')

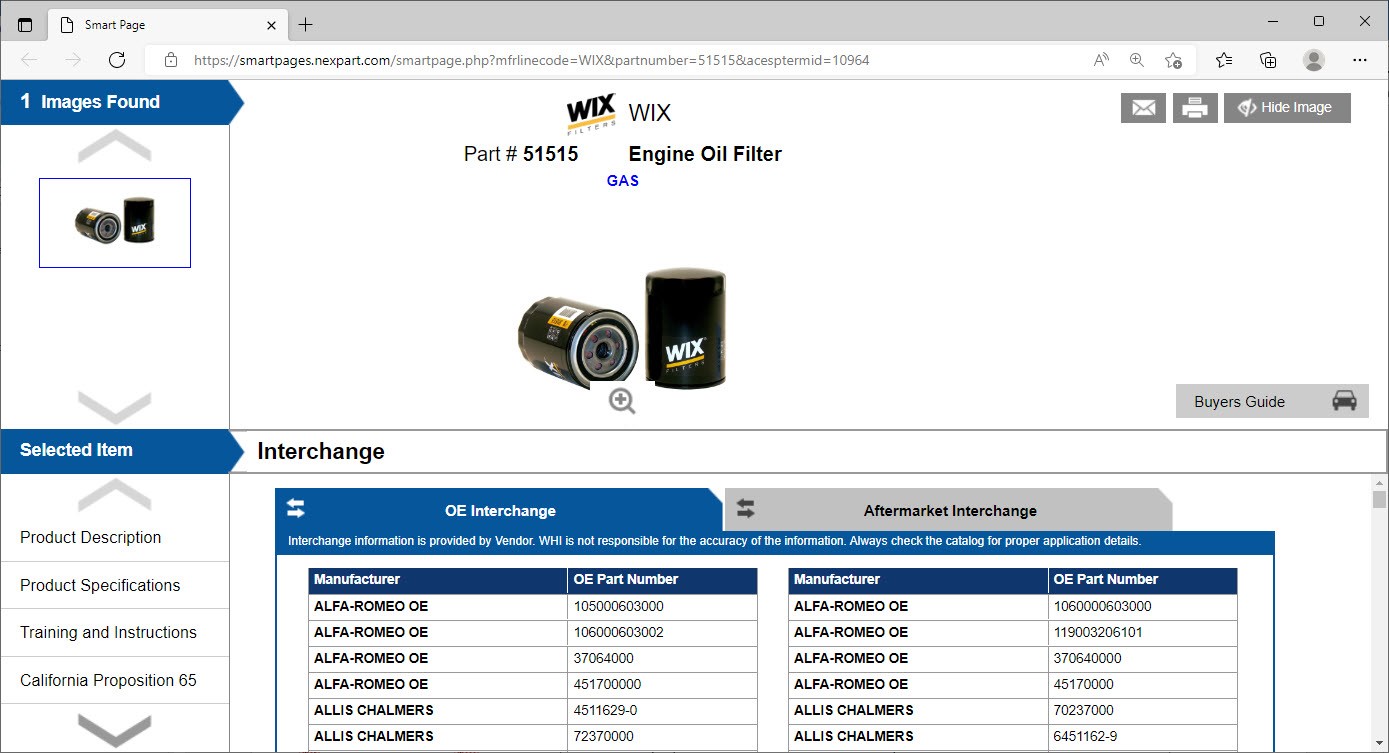

Click the 'Smart Page' link to open a browser with the manufacturer part information.

If a link is not found, a pop-up opens stating the page is not found.

Additionally, if using the Epicor catalog, and Cover to Cover information is available for the entered 'LINE' and 'P/N', the Cover to Cover link displays instead of Smart Page.

Displays the Line Code and Part Number of the (original) part being replaced if the part in focus supersedes a part. The field is blank if a part is not being superseded by the part in focus.

Part Histories

If the part in focus is superseded or supersedes another part and the sales histories are linked, a button displays to "unlink" the part histories. Click the button and the part histories display for the part in focus only. The button changes to 'VIEW LINKED HISTORIES'. Click the button and the part histories again display for both the superseded and supersede parts.

Displays the part histories for the current month.

Displays the part histories for the current year-to-date.

Displays the part histories for the previous calendar or fiscal year.

Displays the part histories for two years before the current calendar or fiscal year.

Displays the part histories for three years before the current calendar or fiscal year.

Displays the part histories for the past 12 months. This value will always display the past 12 months regardless of what the current month is.

Displays the part histories for the past 24 months. This value will always display the past 24 months regardless of what the current month is.

"Stocked parts are inventoried, ordered, and kept on the shelf.

"Real" parts are actual, physical parts as opposed to "parts" used for other things, such as coupons.

"Active" parts can be defined however needed. For example, "active" parts might have a min/max and stock quantity while "inactive" parts do not.

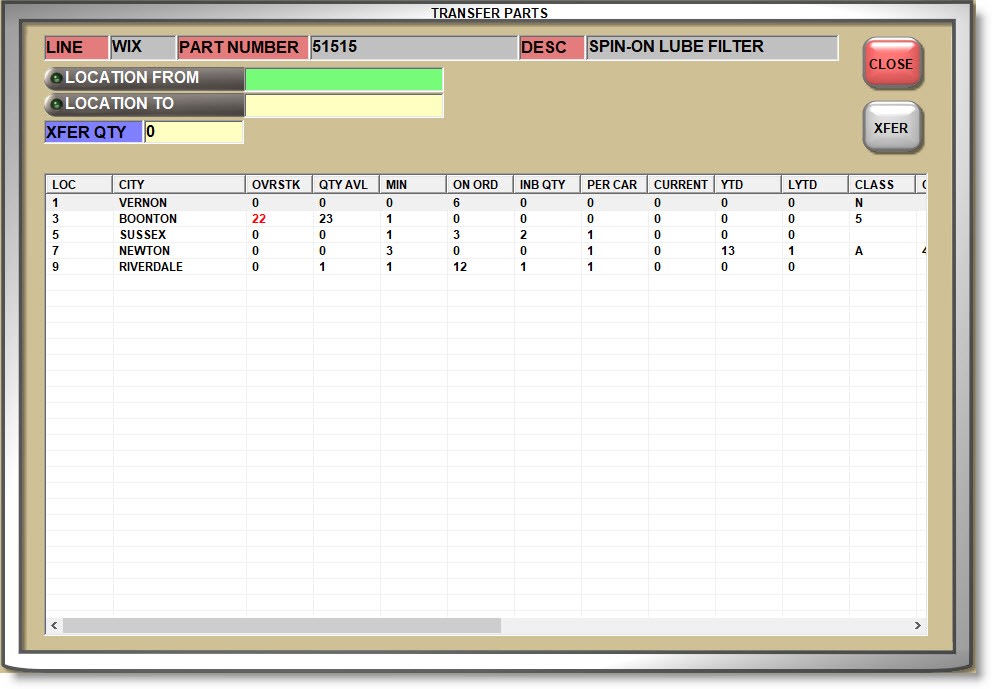

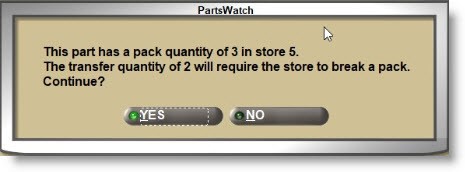

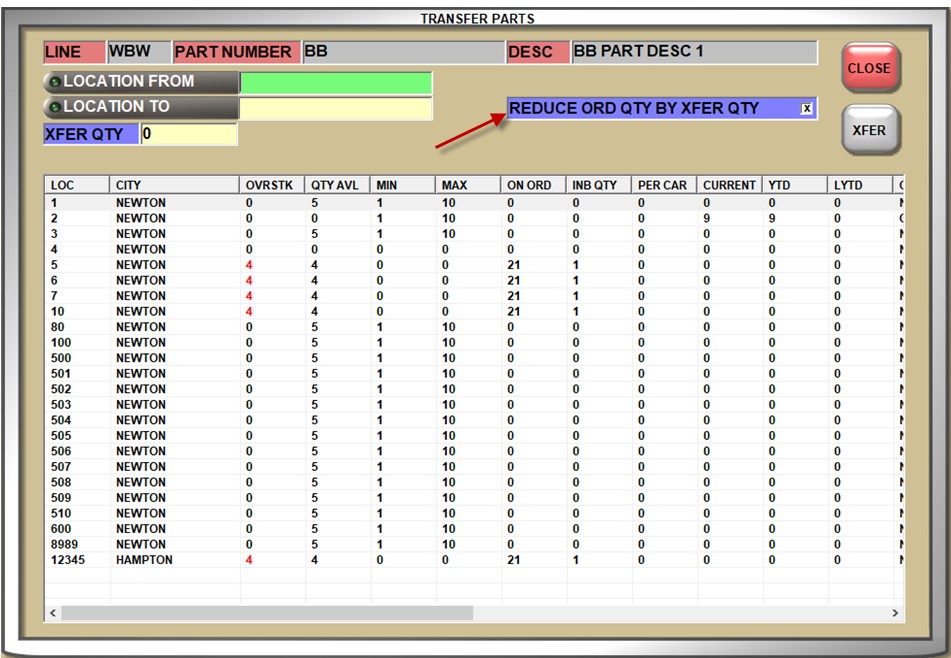

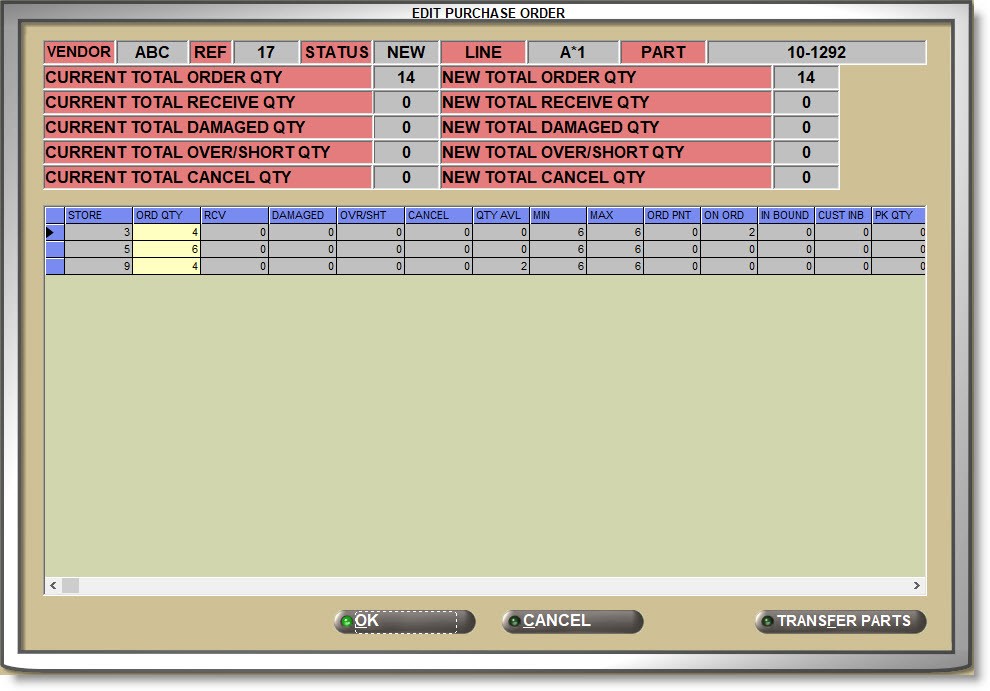

Multi-store only. Click the button to open the 'TRANSFER PARTS' window that is used to "transfer" quantities of the part in focus to/from other locations.

The Line Type field does not have a label. Instead, the field displays 'PARTS', 'FREIGHT', 'LABOR', or 'GIFT CARDS' depending on the Line Code 'TYPE' set up.

Enter the default number of shelf labels that will print for this part. The default can be changed at the time the labels are printed.

A value greater than '0' must be selected in order to use this default when printing labels.

Shelf price labels are normally printed when a price change has occurred.

Purchasing Setups

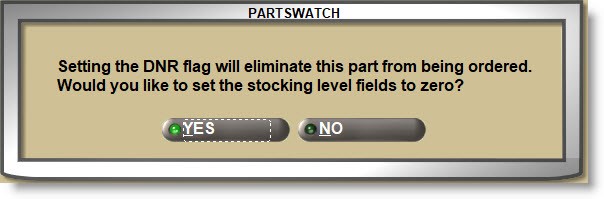

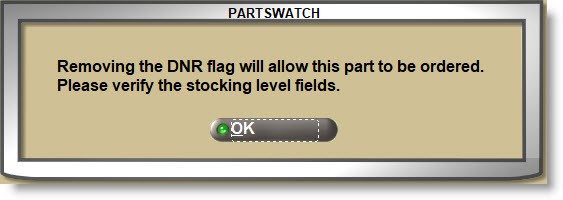

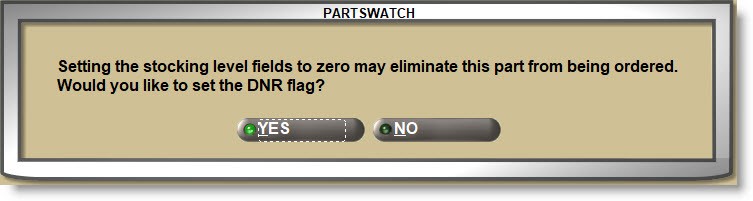

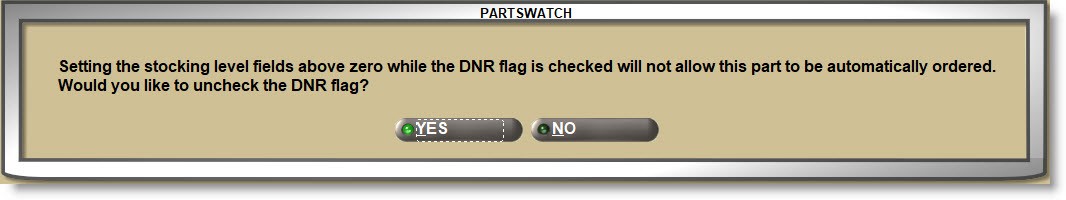

Determines whether or not the part in focus should be considered during purchase order selection.

- Checked: The part will not be considered for reorder during purchase order creation.

- Unchecked: The part is considered for reorder during purchase order creation.

Determines whether or not a part returned at Point-of-Sale is automatically added to a manifest to be returned to the vendor.

- Checked: The part will not be added to a return manifest.

- Unchecked: The part will be added to a return manifest.

Used to "allocate" stock on Return Orders so that, if a subsequent Return Order is created before the first order is transferred out of stock, the parts will not come up again on regular overstock returns.

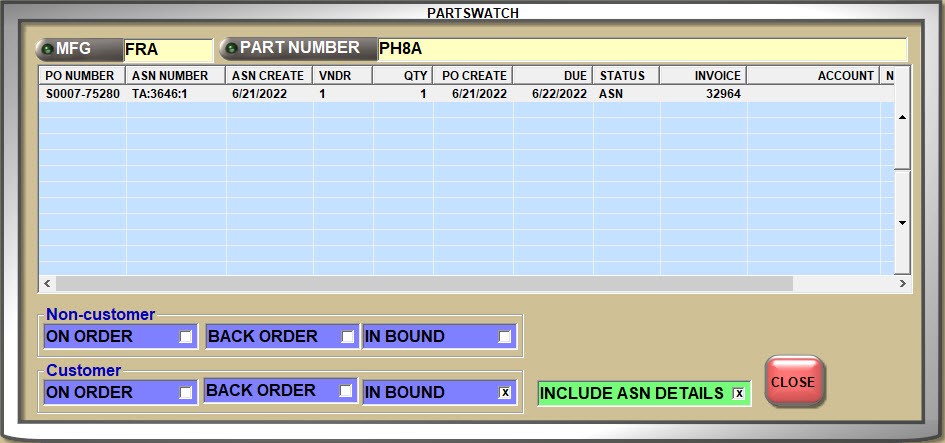

Displays the total quantity of the part in focus on customer sourced orders that is currently inbound on ASNs for information only.

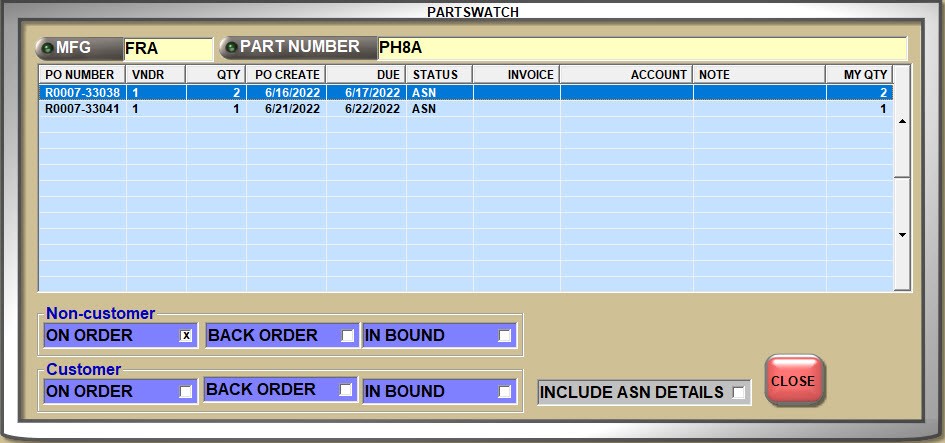

Click the 'CUST INBOUND' button to open the 'ON ORDER / BACKORDER / INBOUND' pop-up displaying customer sourced order information that is inbound on ASNs.

Displays the total quantity of the part in focus that is currently on open customer sourced Purchase Orders for information only.

Click the 'CUST ORDER' button to open the 'ON ORDER / BACKORDER / INBOUND' pop-up displaying customer sourced order information per PO.

Displays the total quantity of the part in focus that is currently on open stocked Purchase Orders for information only.

Click the 'ON ORDER' button to open the 'ON ORDER / BACKORDER / INBOUND' pop-up displaying stocked order information per PO.

Displays the quantity of the part in focus that is currently inbound on an ASN for stocked parts and is for information only.

Click the 'ON ORDER' button to open the 'ON ORDER / BACKORDER / INBOUND' pop-up displaying 'IN BOUND' information.

The 'VENDOR BO' (backorder) field displays the quantity on back order vendor purchase orders for information only.

Click the VENDOR BO button to open the 'ON ORDER / BACKORDER / INBOUND' pop-up displaying stocked order information per PO.

'ON ORDER / BACKORDER / INBOUND' Pop-up

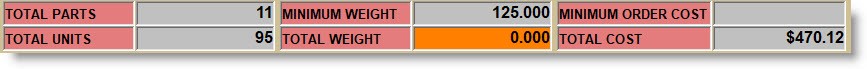

Enter the weight of the part in focus that is used by the Order Create process. If a value is entered in the ‘Min Weight Threshold’ setting under the Options tab in the ORDER CREATE screen, the system will use the value of this field to determine the total weight of the order.

The 'MINIMUM WEIGHT' field on the PURCHASE ORDER DETAIL screen displays the 'Min Weight Threshold' as entered at the time of order creation and if the total order weight is under the threshold, will display the 'MINIMUM WEIGHT' field in a bright orange. This allows the order quantities to be edited up to the threshold if needed.

Allows entry of up to 6 digits with 3 decimal positions ('999999.999').

If the 'TRACK DAY FILL' control is enabled, each time the part is sold at Point-of-Sale, the system tracks the sell quantity to the 'FILL AMOUNT' field. When a Replenishment Order is created, the quantity is cleared and any new sales are then recorded for the next order.

The Replenishment Order method is unique in that the calculated order quantity is not reduced by other orders that are in an 'On Order' status, or by current stock quantities.

Stocking Levels

Enter the minimum number of units for a part to keep stocked on the shelf at any time and used for purchase order creation.

Enter the maximum number of units for a part to keep stocked on the shelf at any time and used for purchase order creation.

Enter the number of units used as the '"order point" for purchase order creation. Can be used with or instead of the 'MIN' and 'MAX' stocking levels.

Enter the quantity that the part is sold in. For example, 4 spark plugs on a 4-cylinder car. If the 'POS DEFAULT SELL QTY' setting is set to 'PER CAR' then the value of this field will display in the 'SELL' field at Point-of-Sale.

A "lead time" is the period between the time parts are ordered and the time it takes a supplier to satisfy the order. Each time a purchase order is received, the system calculates the lead time for the order and saves it in the 'LEAD TIME' field.

When the part's 'LEAD TIME' is zero, then the part is set with the calculated lead time of the current purchase order recieved. Optionally, enter a number from '1' to '999' that represents the number of days between the time a purchase order is finalized and the time the order is received as the starting number used by purchasing when calculating the lead time.

CUR PURCH (current purchased)

Displays the total quantity of the part in focus that was purchased during the current period for information only.

STOCK PROTECT

Determines whether or not 'MIN', 'MAX' and/or 'ORDER POINT' can be updated when running the 'SET MIN MAX ORDER POINT' utility.

Checked: The 'UPDATE' button is available and changes will affect the part table attributes if clicked.

Unchecked: The 'UPDATE' button is not available. The results can be printed or previewed as report only.

Part Filters

Part filters can be optionally used to "group" parts together in a Line or across Lines for purchasing and reporting.

When setting up part filters, first determine how they will be used:

The parts considered for purchase order creation can be filtered by:

- Order Type

- PN Group

- Department

- PN Code

- Category

- Sales Class

Depending on the report, part filters are available to filter report output. For example, all eleven filters are available for the INVENTORY INFO, INVENTORY COUNT, and INVENTORY COST REPORTS.

- Distribution Center (DC) Popularity (POP) Code.

- Up to 5 alphanumeric and special characters.

- Used for inventory reporting.

- Manufacturers Line Class Code.

- 1 alpha or numeric character.

- Only the LINE CLASS Codes set up per line code are available for selection.

- Sales Popularity Code.

- Used to rank and track the popularity of the parts.

- 1 alpha or numeric character in each of the 2 field positions.

- User-defined.

- 1 alphanumeric or special character.

- Part Number Group Code.

- Up to 10 alphanumeric, user-defined characters.

- Part Number Code.

- Up to 3 alphanumeric characters.

- Only the 'P/N CODES' set up per line code are available for selection.

- P/N Codes are used as "sublines" to categorize parts into groups. For example, oil filters can be grouped by conventional, light-duty, heavy-duty, racing, etc.

P/N CODE SETUP

P/N Codes must be set up on the P/N CODE SETUP screen in order to be available to the 'P/N CODE' part filter.

Click here to learn more about setting up P/N CODES.

- Areas or types that parts might be categorized as.

- Can be used in conjunction with 'CATEGORY' to identify specific part types or areas of use. For example, a Department might be ‘HWD’ for hardware.

- Up to 3 alphanumeric and special characters.

- Divisions that parts might be divided into.

- Can be used in conjunction with 'DEPARTMENT' to identify specific types of parts within the areas. For example, ‘NUT’ for nuts or ‘BLT’ for bolts might be categories within the ‘HWD’ hardware department.

- Up to 3 alphanumeric and special characters.

- Product Code.

- Up to 3 alphanumeric and special characters.

- Report Group code.

- Up to 9 alphanumeric and special characters.

Price Levels

Price level 1 and price level 2 as well as all 7 cost levels (price levels 8 – 14) and core cost and core average cost (price levels 15 -16) display with the field names defined in the FIELD NAME SETUP screen.

If the AUDIT PART COST EDITS control is enabled, edits to the price levels are tracked and can be reported from the PART LEDGER COST EDITS REPORT.

LAST XFR IN (last transfer in)

Multi-Store: Since most companies consider transferring of parts between stores "merchandise transfers" as opposed to "merchandise sales", each time a part is transferred in from a transfer account, the date of transfer is updated to the 'LAST XFER IN' field instead of the 'LAST RCVD' (received) date field.

LAST XFR OUT (last transfer out)

Multi-Store: Since most companies consider transferring of parts between stores "merchandise transfers" as opposed to "merchandise sales", each time a part is transferred to a transfer account, the date of transfer is updated to the 'LAST XFER OUT' field instead of the 'LAST SOLD' date field.

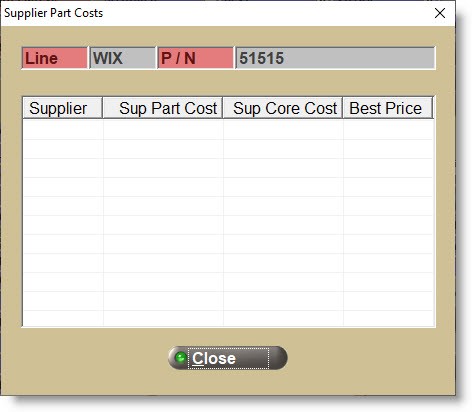

An unlimited number of supplier part costs, per part, can be set up on the SUPPLIER PART COSTS screen and compared for the lowest cost ordering.

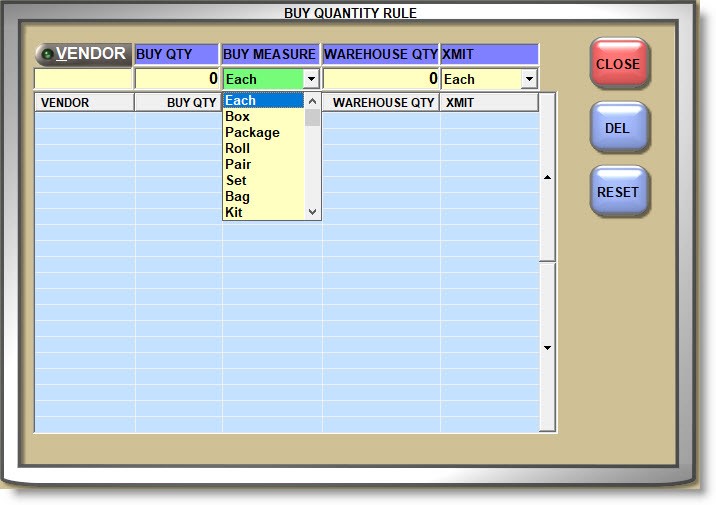

Click the 'BUY QTY RULE' button to open a window used to set up the "rules" needed for vendors that force purchases in pack quantities.

Click the drop-down and select the pack measure the part is normally stored in. This field is no longer used by Point-of-Sale and can be used for information only.

Enter the number of units sold in a "pack". For example, entering ‘1’ in the 'SELL' field may represent ‘1’ unit or ‘1’ box of ‘4’ units. This field is no longer used by Point-of-Sale and can be used for information only.

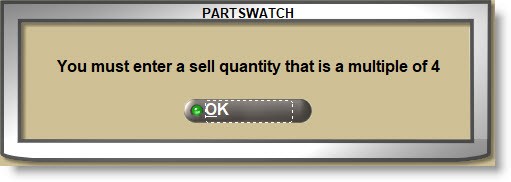

Enter the minimum quantity of the part in focus that must be sold at Point-of-Sale. The system forces the quantity to be sold to the 'MIN SELL' quantity in order to continue with the sale. If a value other than the 'MIN SELL' is entered in the 'SELL' field and the 'Enter' key pressed, the system prompts to enter the correct sell quantity.

Allows entry of 0 – 65535.

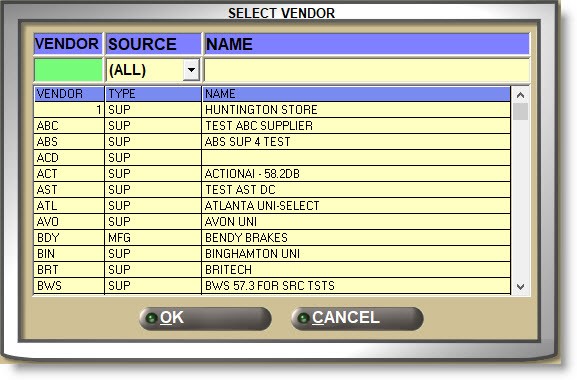

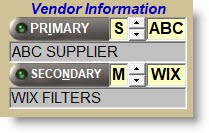

Optionally select a 'PRIMARY' vendor if the part is normally purchased from the same vendor. Select a 'SECONDARY' vendor to order from in the event the part is not available from the primary vendor. Both fields are used as filters during purchase order creation.

The 'DESIGNATION' setting on the ORDER CREATE / PURCHASE ORDER PROFILE field defaults to ‘All Parts’, however, setting the 'DESIGNATION' to 'PRIMARY' filters the parts to only consider those with the setting of 'PRIMARY' for the designated vendor in the order. 'SECONDARY' is used the same way.

The setup consists of four sections:

- Middle: Defaults to ‘M’ (manufacturer). Click the small up/down buttons to change the field to ‘S’ (supplier).

- Left: Click the 'PRIMARY' button and, if an ‘M’ displays in the middle section, the 'BROWSE LINE CODES' pop-up opens to search for/select a Line Code. All Line Codes are available for selection regardless of the 'USE AS VENDOR' setting. If an ‘S’ displays in the middle section, the 'BROWSE SUPPLIERS' pop-up opens to search for/select a Supplier Code.

- Right: Enter a Line Code or Supplier Code. If one is selected from the browser window, the code will display in the field.

- Lower: Displays the selected Line or Supplier name for information only.

Whether the 'EDIT' button is enabled or not, click the 'UTIL' button to open a window with a number of features.

Click the 'NOTES' button to display the 'INVENTORY NOTES' window used to set up a part note for Invoicing and/or Purchasing.