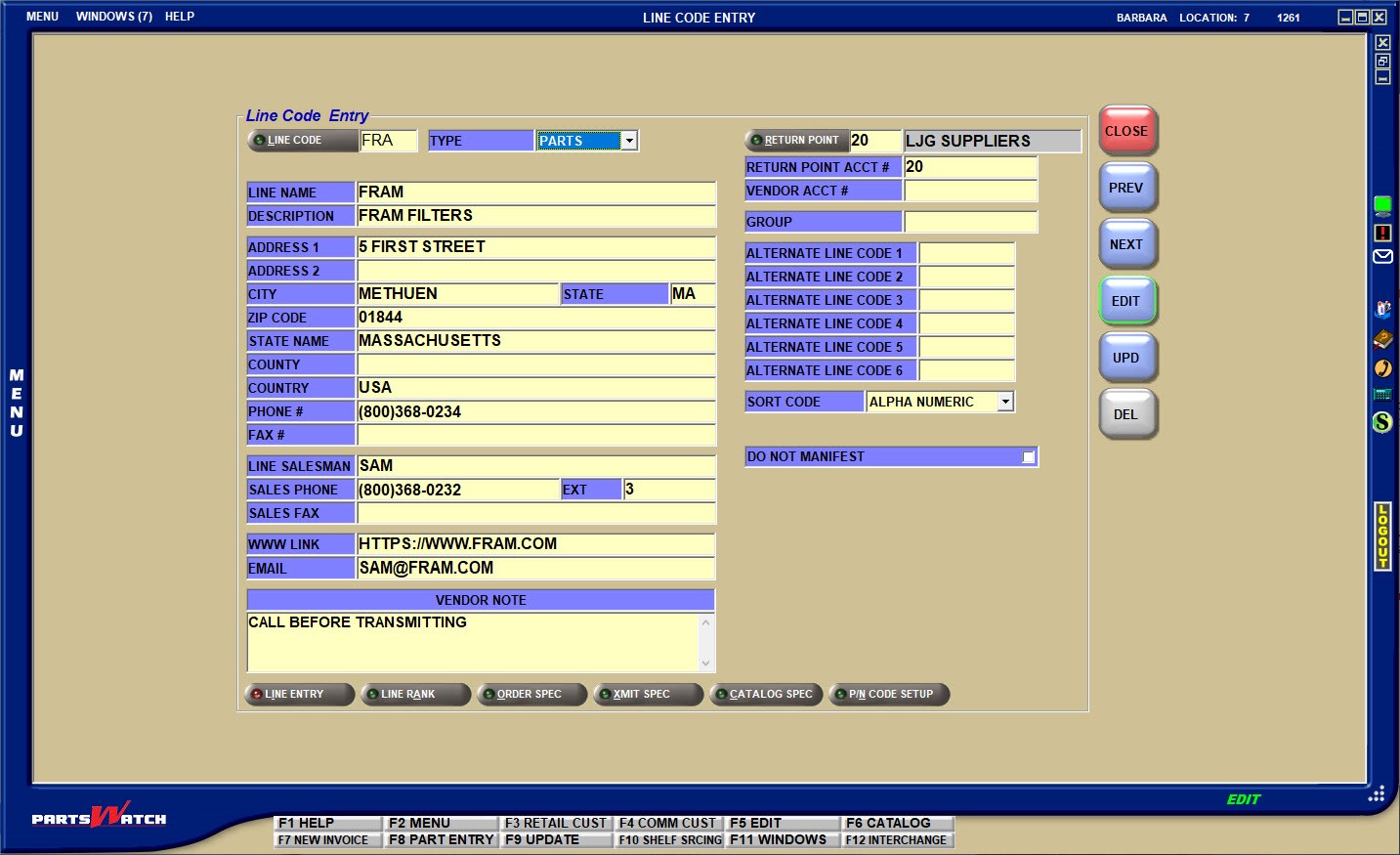

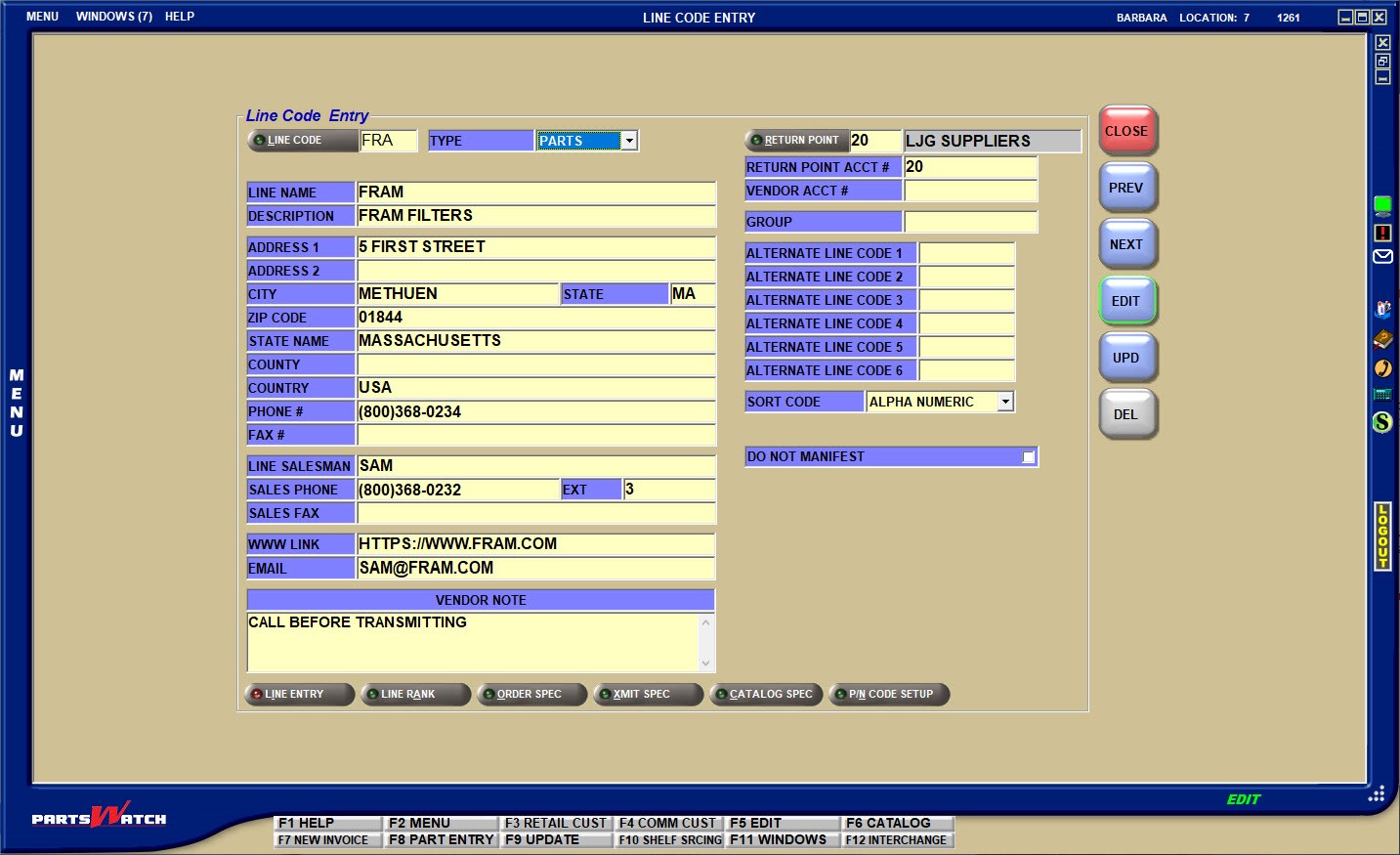

Line Code Entry

The LINE CODE ENTRY is used to set up and maintain the manufacturers whose product lines are inventoried and used by the store for sales, purchasing, and inventory reporting.

Menu Path: Vendor, Line, Line Entry, LINE CODE ENTRY screen

Like most PartsWatch maintenance screens, the 'EDIT' and 'UPD' (update) buttons must be used when changes are made. 'EDIT' must be "off" when entering a line code and "on" when changing the line settings. 'UPD' must be clicked to save the changes.

Adding Lines Codes

Depending on the 'LINE CODE SETUP' system control, up to 3 letters, numbers, and/or special characters; or only letters and numbers, but no special characters can be entered. Each Line Code must be unique.

Press the 'Enter' key and if the 'LINE CODE' does not already exist, a prompt opens to add the Line Code. Answer 'YES' and the Line Code is added.

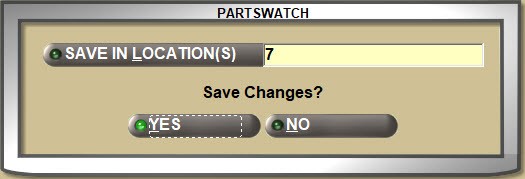

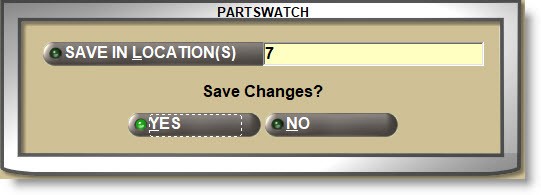

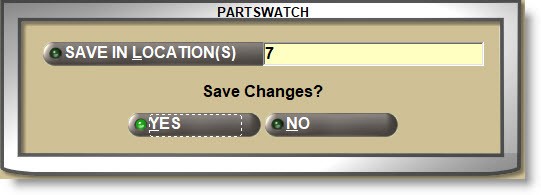

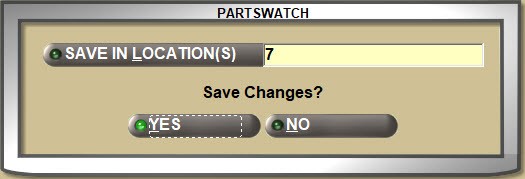

Save in Multi-Stores

Pressing the 'Enter' key opens a pop-up to add the Line Code in depending on:

- 'ALLOW SAVE LINE INFO IN MULTIPLE LOCATIONS' User Security Proc must be enabled for edit.

- The settings on the EMPLOYEE SETUP screen allow access to more than one location.

The pop-up defaults to the current location. Click the 'SAVE IN LOCATIONS' button to open the multi-select 'BROWSE LOCATIONS' window and check one, multiple, or all locations. Answer 'YES' to save the changes to the selected locations, and 'NO' to cancel the process.

TYPE

Select the 'TYPE' of product sold under a Line Code for reporting as:

- 'PARTS' for all inventoried items.

- 'FREIGHT' to track any parts under the line as shipping costs.

- 'LABOR' to track any parts under the line as labor charges.

- 'GIFT CARDS' to track any parts under the line as gift or merchandise cards.

If set to 'GIFT CARDS' a 'Gift / Merchandise Card Setup' section displays for additional setup.

MINIMUM LOAD AMOUNT

Enter the least amount that can be loaded on a gift card or merchandise card. Allows from '0.00', (no minimum amount) to '9999.00'.

MAXIMUM LOAD AMOUNT

Enter the greatest amount that can be loaded on a gift card or merchandise card. Allows from '0.00' (no maximum amount) to '9999.00'.

Note: The 'MINIMUM LOAD AMOUNT' is ignored when a value more than the 'MAXIMUM LOAD AMOUNT' is refunded and less than the minimum amount is being forced onto a merchandise card. For example: If a 'MINIMUM LOAD AMOUNT' is set to $10.00, the 'MAXIMUM LOAD AMOUNT' is set to $200.00 and the amount forced on a merchandise card is $207.00, the system creates two merchandise cards, one for $200.00 and the other for $7.00.

MINIMUM DENOMINATION

Enter the lowest denomination dollar amounts that can be loaded on gift card sales and reloads. Allows from '0.00' to '9999.00'. For example:

- 1.00 – Any value can be loaded (1.00, 51.00, 99.00, 100)

- 5.00 – Amounts can only be loaded in 5.00 increments (5.00, 15.00, 55.00, 100)

- 10.00 – Amounts can only be loaded in 10.00 increments (10.00, 50.00, 100.00)

Note: The 'MINIMUM DENOMINATION' field is ignored for refunds loaded and reloaded on gift and merchandise cards.

Optionally enter the manufacturer information:

- 'LINE NAME'

- 'DESCRIPTION'

- 'ADDRESS 1' through 'COUNTRY'

- 'PHONE #'

- 'FAX #'

Optionally enter the contact information:

- 'LINE SALESMAN'

- 'SALES PHONE'

- 'SALES FAX'

- 'WWW LINK' (website URL)

- 'EMAIL' address

- 'VENDOR NOTE' - Enter up to 12 alphanumeric characters only.

Note: Displays for POs created from the PURCHASE ORDER PROFILE screen, which allows line orders to be created, and does not display for orders created from the ORDER CREATE screen.

Optionally set up manifest information:

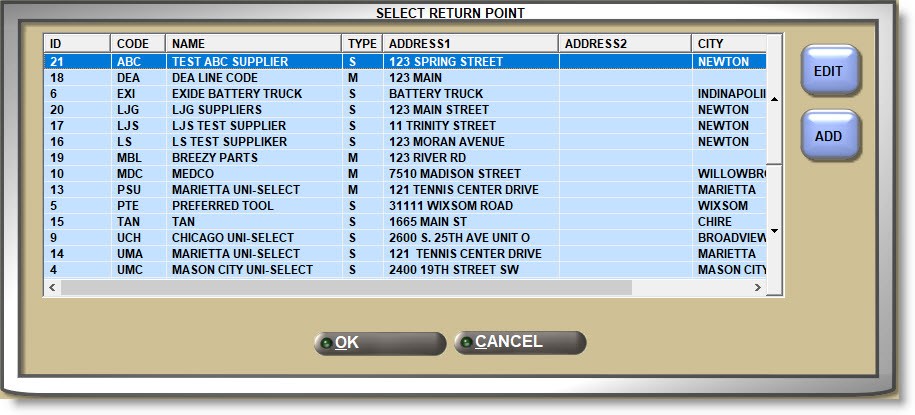

RETURN POINT

Identifies the address where core and warranty parts returned at Point-of-Sale are sent back to the manufacturer.

The system looks at the 'RETURN POINT' in the following hierarchy:

- Supplier

- Line Code

- Store-level

If a 'RETURN POINT' is set up for a Line Code, it is used as an override to the Supplier and the store 'RETURN POINT'.

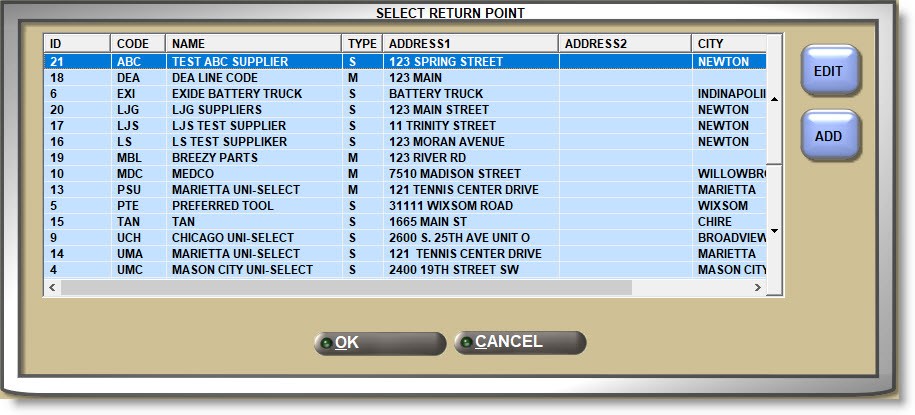

Enter a 'RETURN POINT' and if it does not exist, the 'SELECT RETURN POINT' window opens to select one, or click the 'RETURN POINT' button to open the window. Click the column headers to re-sort the rows to assist in searching for a return point. Highlight a row and click the 'OK' button to select the return point.

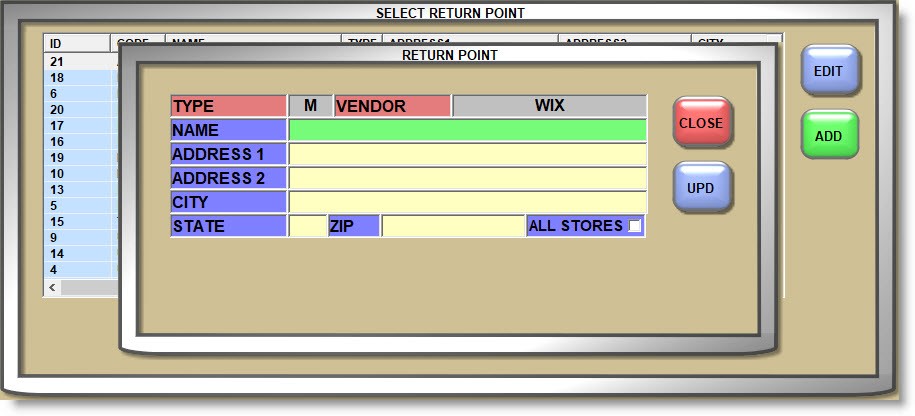

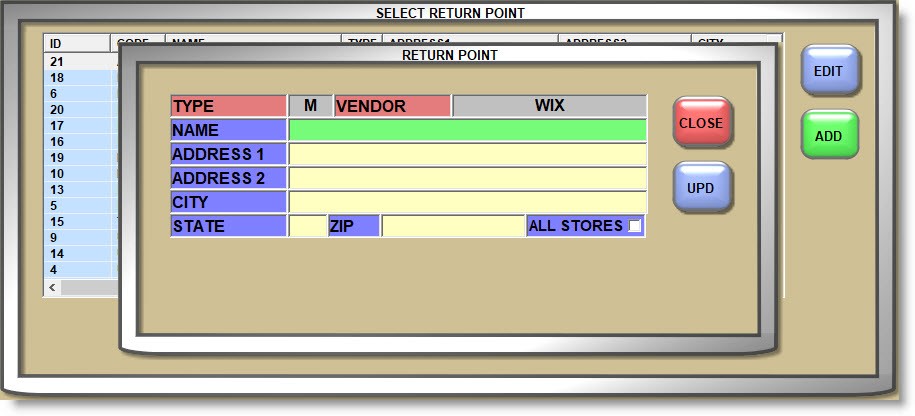

ADD

If the 'RETURN POINT' does not currently exist, with the 'SELECT RETURN POINT' window open, click the 'ADD' button to open the 'RETURN POINT' pop-up to add one. Enter the 'NAME', 'ADDRESS 1', 'ADDRESS 2', 'CITY', 'STATE', and 'ZIP'. Once added, it is available from the 'SELECT RETURN POINT' window as the store default 'RETURN POINT' or for selection for all Line and Supplier setups.

For multi-store setup, check the 'ALL STORES' checkbox if the 'RETURN POINT' is available in all stores.

EDIT

With the 'SELECT RETURN POINT' window open, highlight a row in the grid and click the 'EDIT' button. Edit the 'NAME', 'ADDRESS 1' and/or 'ADDRESS 2', 'CITY', 'STATE', and 'ZIP' as needed. The 'ALL STORES' checkbox cannot be edited.

RETURN POINT ACCT #

Enter up to 12 alphanumeric and special characters for the account number assigned to this line. The number is output on the manifest printed report but is not transmitted to the vendor with the return manifest.

GROUP

If multiple line codes are "linked" together for reporting, enter up to 8 alphanumeric and special characters in the applicable Lines Codes. Select the 'ALL LINES LIST' report output from the VENDOR LINE REPORTS screen and sort by 'Line Groups' to report by 'GROUP'.

ALTERNATE LINE CODE 1 (through) ALTERNATE LINE CODE 6

Since parts can be ordered from multiple sources, each with its own line code, enter the line code used by the sources if different from the line code used in PartsWatch. The 'USE ALT MFG' setting on the LINE CODE XMIT SPECIFICS screen provides the ability to select the 'ALTERNATE LINE CODE (1 through 6)' to transmit to each vendor.

SORT CODE

Select the 'SORT CODE' which is the method used to index part numbers. Sort Codes are used to order the parts and depending on the manufacturer, different sorts will work better for different lines.

- 'ALPHA NUMERIC' – For lines with small part numbers.

- 'ALPHA LONG PAD' – For lines with large part numbers. If selected the 'SORT PAD' field displays to enter the number of characters for the first sort break.

- 'PREFIX-BODY-SUFFIX'

- 'BODY-PREFIX-SUFFIX'

- 'STRIPPED-FULL' - Sorts the same as 'ALPHA NUMERIC' except this selection ignores all dashes/slashes and special characters.

- 'STRIPPED-PARTIAL' - Sorts the same as 'ALPHA NUMERIC' except this selection ignores dashes/slashes between a letter and number/number and letter.

All functions that print or display part numbers use the part 'SORT CODE' method including:

- Inventory reports

- Utility reports (e.g. Inventory Mass Update, LISA, PATI, and Part Ledger)

- Any invoicing sequencing by part number

- Any pop-ups that list part numbers using a start or end part number

- Purchase Orders

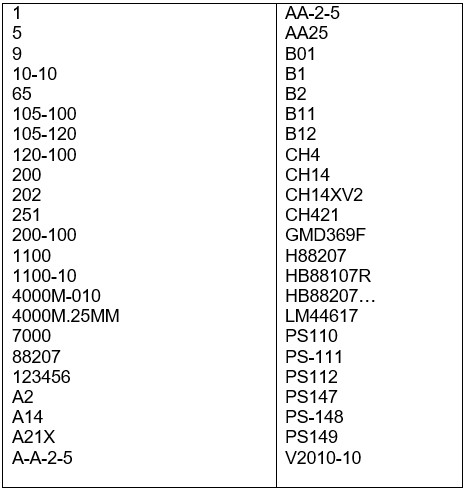

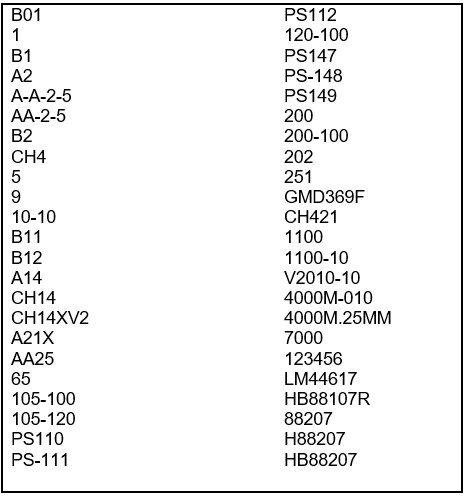

Understanding Sort Codes

Sort Codes are used to order the parts and depending on the manufacturer, different sort methods will work better for different lines.

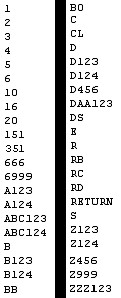

All Sort Code Methods:

The current part sort routines ensure a logical sort output. Each time there is a character change in the number, it is known as a “sort breakpoint”. In the example below, the "–" is the breakpoint.

1-2

1-3

1-200

1-212

1-300

1-345

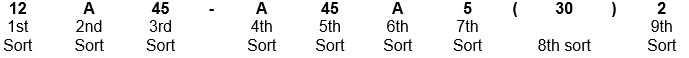

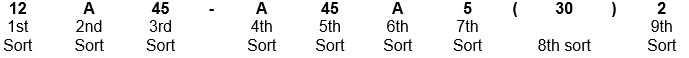

To further illustrate the point, in a number like 12A45-A-45A5(30)2, each time a new character type is encountered, a new break is assumed. So the breakpoints in the example are "A", "-", "A", "-", "A", "(", and ")". Each of these represents a point within the number where a change occurred.

The system uses each of these breakpoints to sort by. In the above example, the part has 9 sort breaks, as follows:

ALPHA NUMERIC - Generally used for lines with smaller part numbers.

- The 'ALPHA NUMERIC' method sorts numbers in counting order, then letters in alphabetical order.

- Using the 'ALPHA NUMERIC' sort, each sort break cannot have more than 8 characters, or the sort routine will take the last 8 rightmost values and truncate all values to the left of 8 in order to sort the number.

- For example:

Part Number: 12466745671369998A828

Part Number: 22001230000100230A828

- In both examples above, the part has 17 characters in the first sort breakpoint ("A" is the breakpoint).

- The system takes the right-most 8 characters and truncates the rest of the number to sort.

…71369998A828

…00100230A828

- The truncation is only used to figure out the sort. The full, actual part number is still displayed for all output, however, the order may not look accurate because of the way it is sorted.

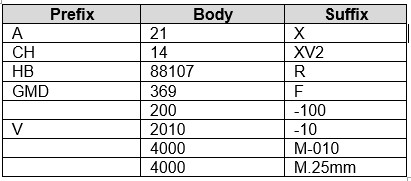

ALPHA LONG PAD - Generally used for lines with longer part numbers.

- The 'ALPHA LONG PAD' method, sorts parts the same as the 'ALPHA NUMERIC' except, if selected, an additional field 'SORT PAD' displays to enter the number of characters the routine will use as the sort breakpoint with the most characters. In the above example, "17" would be the breakpoint, and for additional caution, enter "19" in the 'SORT PAD' and the parts are sorted as expected.

Part Number: 12466745671369998A828

Part Number: 22001230000100230A828

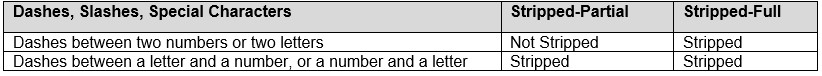

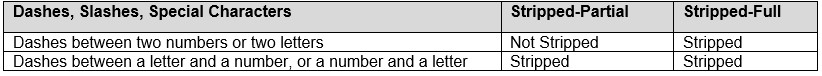

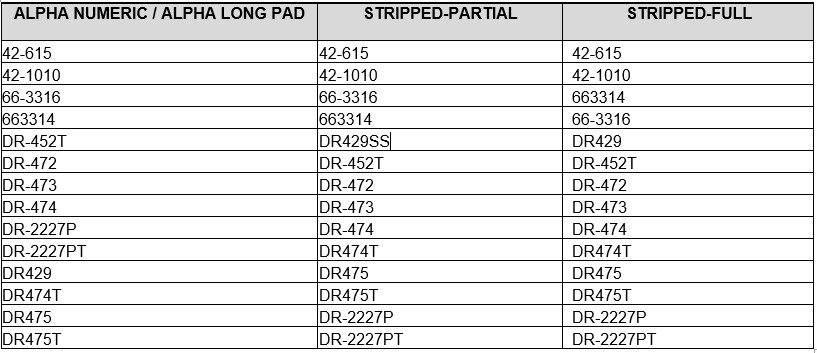

STRIPPED-PARTIAL/STRIPPED-FULL - Generally used for lines with and without dashes between letters and numbers.

- 'STRIPPED-PARTIAL' sorts parts the same as the 'ALPHA NUMERIC' and 'ALPHA LONG PAD' sorts, except dashes, slashes, and other special characters that are between a letter and a number, or a number and a letter are ignored. It does not ignore dashes that are between two numbers or two letters.

- 'STRIPPED-FULL' sorts parts the same as the 'ALPHA NUMERIC' and 'ALPHA LONG PAD' sorts, except all dashes, slashes, and other special characters are ignored.

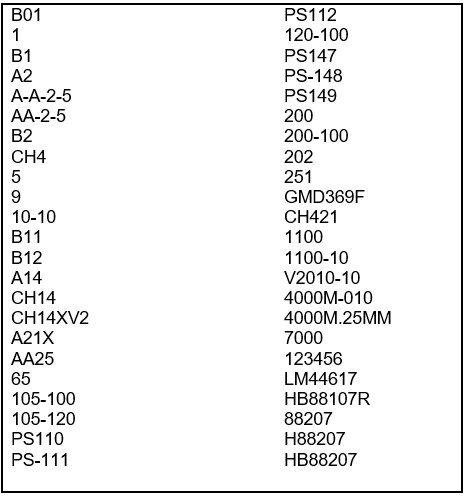

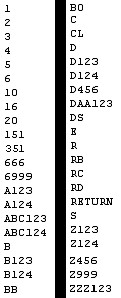

The following is an example of the part order using the different part sorts:

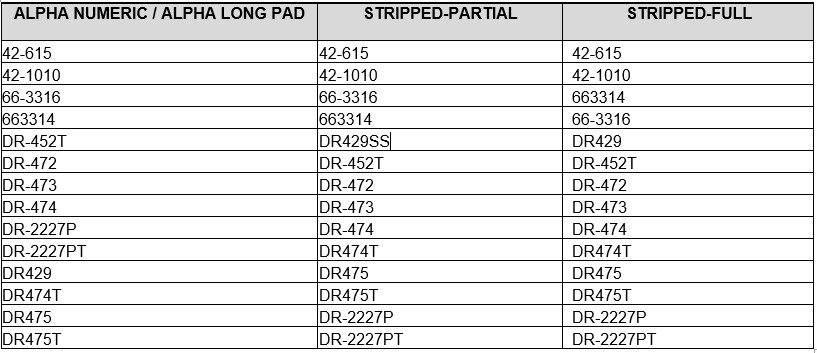

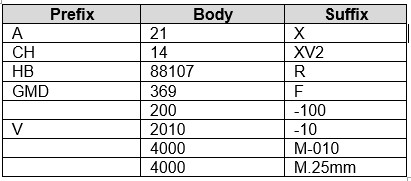

PREFIX-BODY-SORT - Sorts alphanumeric part numbers by prefix first, then by the body, then by the suffix.

- A "prefix" is always made up of the alpha characters at the beginning of a part number. Prefixes may or may not be present, and can be a varying number of characters.

- The "body" of the part number begins with the first numeric character. It includes everything up to a **significant dash (-) and is sorted numerically in counting order.

- The “suffix” is any trailing alpha characters or any trailing data after a **significant dash (-).

Examples:

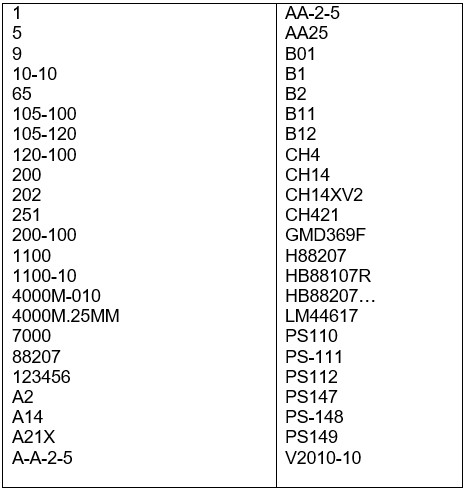

Example of sort:

BODY-PREFIX-SUFFIX - Sorts by the body of the part number, then by the prefix and then by the suffix. For example, AC spark plugs R46TS sorts on the:

- The body (numeric portion) is sorted numerically (counting order).

- Dashes between an alpha and a numeric character are *insignificant. For example, the numbers PS147, PS-148, and PS149 will report in that order, ignoring the dash.

- Dashes between two numbers are **significant.

Example of sort:

*Note: Dashes between an alpha and a numeric character are insignificant. For example, the numbers PS147, PS-148, and PS149 will report in that order, ignoring the dash.

**Note: Dashes between two numbers are significant. Dashes between two numeric characters ARE significant. Numbers with dashes first sort on the numbers before the dash, in counting order, and then by the numbers after the dash, in counting order. For example, numbers with dashes sort as follows:

10-10

105-100

105-120

120-100

1100

1100-10

DO NOT MANIFEST

Determines whether or not defective/warranty and core returns at Point-of-Sale for this line are not returned to the vendor.

- Checked: Defective/warranty and core returns at Point-of-Sale for this line are not returned to the vendor.

- Unchecked: Defective/warranty and core returns at Point-of-Sale are put on a return manifest.

Editing Setups

To edit a Line Code, enter an existing line code in the 'LINE CODE' field and it will display all information already set up on the screen. The 'LINE CODE' button can be used to open a browser to locate an existing Line Code.

- Click the 'EDIT' button ('F5' key) to edit.

- Click the 'UPD' button ('F9' key) to save changes.

For multi-stores: Clicking the 'UPD' button opens a pop-up to select the locations to save the changes in depending on:

- The 'ALLOW SAVE LINE INFO IN MULTIPLE LOCATIONS' User Security proc must be enabled for edit.

- The settings on the EMPLOYEE SETUP screen allow access to more than one location.

- The pop-up defaults to the current location. Click the 'SAVE IN LOCATIONS' button to open the multi-select 'BROWSE LOCATIONS' window and check, one, multiple, or all locations. Answer 'YES' to save the changes to the selected locations.

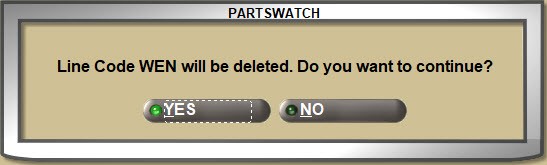

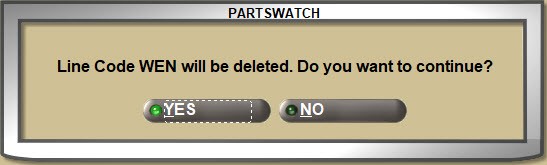

Deleting Line Codes

With a 'LINE CODE' displayed, click the 'DEL' button ('Delete' key) to delete a line code if the 'ALLOW SINGLE LINE DELETE' User Security proc allows, and a prompt opens:

Answer 'YES' and:

- If the line code does not contain any parts, the line is deleted and no longer accessible. The same line code can be entered if needed.

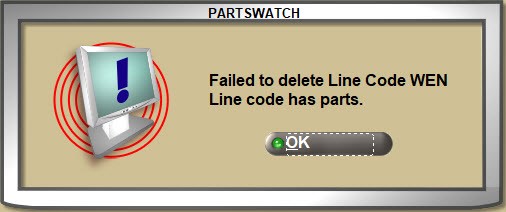

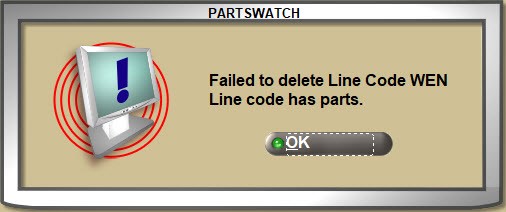

- If the line code contains any parts, the line code will not be deleted and instead a prompt opens:

Multi-Store Delete

If the Line Code exists in more than one store, the Line Code will be deleted in the current store only. Open each store to delete the Line Code in that store.

When a line code is deleted, if any of the following records associated with the deleted line code exist, they will also be deleted:

- All 'PN CODES' for that line codes

- All excluded 'PN CODES' for that line code

- All line 'CLASS CODES'

- All Line Code 'PRICING SERVER' rules

Note: Deleted lines are not deleted from customer price plans or from the Line Purchases Report. The Record Retention Utility deletes these records at the appropriate time.