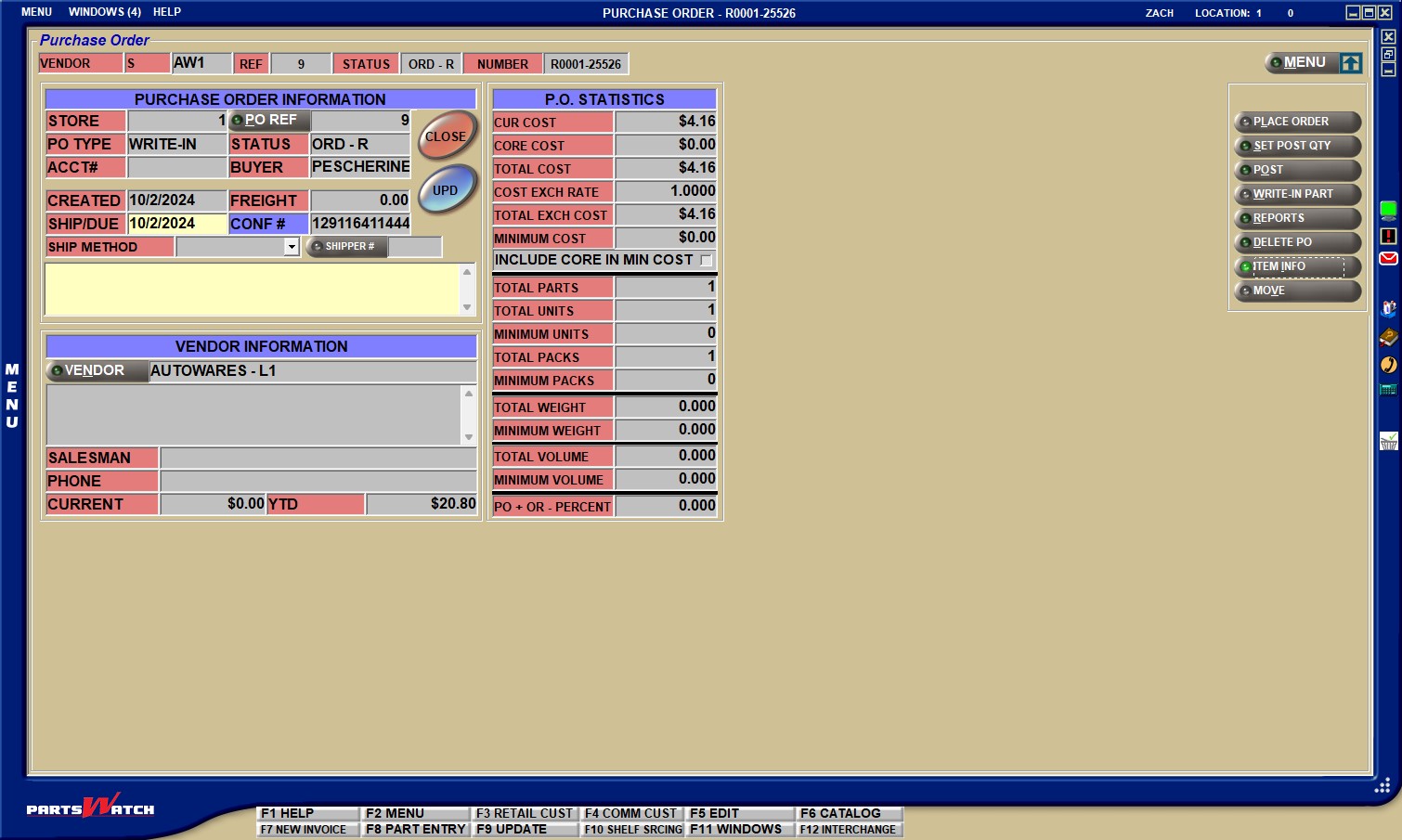

Purchase Order Screen

The PURCHASE ORDER edit/detail screen is used to view a purchase order, and edit purchase order details before sending to the vendor, if needed. The detail/edit screen displays automatically after a purchase order is created.

Editable fields display in off-white and non-editable fields display in gray. To edit, double-click on a field and type in the new value. Once data is entered, the 'Enter' key moves the cursor to the right. Use the arrow keys to move the cursor up, down, left, or right.

Menu Path: Purchasing, Purchasing Dashboard. The PURCHASING DASHBOARD screen displays listing all purchase orders. Double-click on the purchase order, or single-click and press 'Enter', or right-click and select 'EDIT PO' from the right-click menu. The PURCHASE ORDER edit/detail screen displays.

The screen title displays either PURCHASE ORDER or RETURN ORDER based on the type of order selected, and then the order number. For example: PURCHASE ORDER - S0001-175231.

Purchase Order Setups

Displays the vendor code. Click the button to display the 'SELECT VENDOR' window to search for a vendor.

Displays the system-generated reference number assigned to the purchase order when the PO was created and the 'STATUS' of the purchase order.

Displays the purchase order number.

Displays a value, typically four (4) alphanumeric characters, sent with a communication file from the vendor and used to identify the PO as a Deal PO. Available when Deal Order functionality is enabled.

Displays the following options for creating/editing a purchase order:

- 'FINALIZE' - Changes the PO from a preview to an actual PO by updating the 'ON ORDER' quantities in the part table. Assigns the PO a status of 'FINAL' and removes any items that were edited to a zero order quantity.

- 'PLACE ORDER' - Transmits the PO to the vendor if transmission setups have been established for the vendor in the SUPPLIER XMIT screen. 'PLACE ORDER' can only be used once the PO has been finalized and changes the status to 'ORD'. If an XMIT record has not been set up, the 'SETUP eTRANS' window displays for the user input before clicking the 'PROCESS' button to transmit the PO.

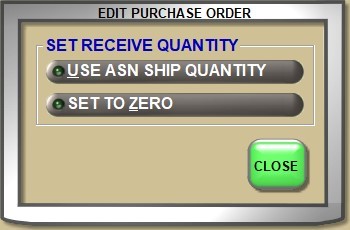

- 'SET RECV QTY' - Displays the 'EDIT PURCHASE ORDER' window to determine whether to edit the PO by setting the received quantity for all parts on the order to either the full order quantity or to zero. 'SET RECV QTY' can only be used once the PO has been finalized.

- 'RECEIVE' - Receives the order into stock and optionally prints the 'RECEIVING REPORT' and/or 'EXCEPTIONS REPORTS'.

- 'WRITE-IN PART' - Allows a part to be manually added to the purchase order as long as the PO has not yet been transmitted. In-File or Not-In-File parts may be added.

- 'REPORTS' - Displays the 'PO REPORTS' window to generate the 'HISTORY REPORT', 'PURCHASE ORDER REPORT', 'RECEIVING REPORT', and 'SUPPLIER DISCOUNT REPORT'. The 'RECEIVING REPORT' is used once received quantities are entered but before the purchase order is transferred to stock. The 'PURCHASE ORDER REPORT' is generally printed immediately after the order is created to assist with the editing procedure.

- 'DELETE PO' - Deletes the purchase order. If the order has already been finalized, on order quantities are removed from the part file. Note: The 'ALLOW EDIT NID PO' flag in the SUPPLIER ORDER SPECIFICS screen and LINE CODE ORDER SPECIFICS screen must be checked in order to delete/edit the order quantity of a part on a NID PO. If not, an error message displays. The 'ALLOW EDIT NID PO' flag controls adding or deleting parts, or increasing or decreasing order quantities on the orders, or deleting the entire order. It does not include editing the receipt quantities when receiving the parts into stock. Regardless of the 'ALLOW EDIT NID PO' flag value, once a PO is in 'ORD', 'XMIT', or 'ASN' status, the 'ON ORDER' quantities can no longer be edited.

- 'PO INFO' - Displays 'PURCHASE ORDER INFORMATION' and 'VENDOR INFORMATION' for the current PO. When clicked, the button name changes to 'ITEM INFO'. Click the 'ITEM INFO' button to re-display the PURCHASE ORDER EDIT/DETAIL screen.

- 'SPLIT' - Enables the splitting up and moving of multiple parts from one return order to another return order (for the same vendor only) in order to meet that vendor's requirements. The 'SPLIT' button will be disabled if the return order cannot be edited. Opens the 'Split Parts From Order' pop-up.

- 'MOVE' - Moves some or all parts from an existing purchase order to a new or existing purchase order for the same or different supplier. Enabled for any purchase order that is editable. POs that have already been transmitted are not editable and this button is disabled. Only visible when a PO displays, 'SPLIT' displays for Return Orders.

Displays a line code in the first box and a part number in the second box to search for a part number. Or, enter a part number without a line code. Or, click the 'FIND' button to display the 'FIND PART' window to search for a part.

If the part number exists on the PO, then the page containing the part number displays with an arrow in the first column pointing to the item.

Displays the layout format name. Click to display the PO EDIT LAYOUT SETUP screen used to create a new layout or edit an existing layout.

The system allows the creation of your own layout for the PO edit screen. The pre-set default layout, called 'EDIT LAYOUT 1' displays the line code (if a supplier order), current cost, core, and order quantity. If no other layouts have been created, this layout is used by default.

If other layouts have been created, the last layout that was accessed by this user is used by default. Even if the 'EDIT LAYOUT 1' is selected last, the last custom setup displays when the screen is reopened. These custom layouts allow for many other part fields to be selected and displayed in any order. Certain fields allow you to specify whether the parts can also be edited while in purchasing. The PO EDIT LAYOUT SETUP screen is used to select the part fields that display in the layout and specify if the fields can be edited. If parts are edited from the PURCHASE ORDER screen, the values are updated to the part table at the time of edit.

Displays a value of 'Yes' or 'No' when the order has either been authorized for return, or has not yet been authorized for a return.

Indicates that any parts not available for sale at the requested time are placed on back order, when checked. When a part is available, the customer should be notified. When unchecked, parts that are not available are not placed on back order for this customer.

The 'EDIT SAVE BACKORDER FLAG' User Security proc, located in the USER SECURITY SETUP screen under 'PURCHASING', 'PURCHASING MAIN MENU', determines whether or not the flag can be edited.

- When set to 'NOT VISIBLE', the 'SAVE BACKORDER' flag is hidden in the PURCHASE ORDER detail screen.

- When set to 'VIEW ONLY', the 'SAVE BACKORDER' flag displays but is unavailable to edit in the PURCHASE ORDER detail screen.

- When set to 'ALLOW EDIT', the 'SAVE BACKORDER' flag in the PURCHASE ORDER detail screen is available for edit.

Note: Regardless of the value of the 'SAVE BACKORDER' flag, the 'PUT THE DIFFERENCE ON BACKORDER' flag in the 'RECEIVE PO' window is unavailable and not editable.

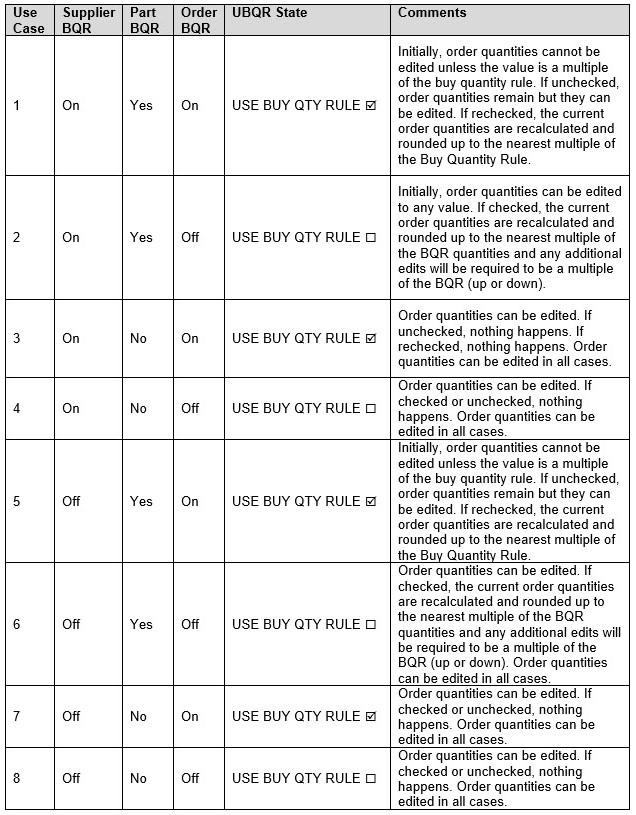

USE BUY QTY RULE (Purchase Orders) / RTN FULL PACKS ONLY (Return Orders)

These checkboxes only display if the 'Show Use Buy Qty Rule Checkbox' setting is checked on the STORE PURCHASING SETUP screen, 'PURCHASING' tab, and if the user has appropriate user security access to view it via the 'SHOW USE BUY QTY RULE FLAG' proc on the USER SECURITY SETUP screen.

The table below identifies the behavior of these checkboxes, both for purchases and returns.

- The "Supplier BQR" column refers to the setting 'USE BUY QTY RULE' set on the SUPPLIER ORDER SPECIFICS screen. This setting identifies whether a supplier enforces buy quantity rules or not. (For returns, the setting is 'RTN FULL PACKS ONLY' on the same screen.)

- The "Part BQR" is set on the part record by Vendor on the MAIN PART ENTRY screen.

- The 'USE BUY QTY RULE' is set on the 'Options' tab of the ORDER CREATE screen for the purchase order. This setting can be modified on an order by order basis.

- The "UBQR State" refers to the state of the 'USE BUY QTY RULE' checkbox on the PURCHASE ORDER screen when it is initially created.

Checking or unchecking the 'RTN FULL PACKS ONLY' on return orders will follow the same rules as described above.

Note: In order for 'RTN FULL PACKS ONLY' functionality to be honored, the 'USE BUY QTY RULE' must also be enabled on the return order.

If the return order quantity is not an increment of the buy quantity, the return order quantity will be rounded down to the vendor buy quantity when the 'RTN FULL PACKS ONLY' checkbox is checked.

If the field 'BUY MSR' is used in the display layout of the purchase order on the PURCHASE ORDER screen, and the 'USE BUY QTY RULE' checkbox is unchecked, 'ORD QTYs' are updated and converted to "eaches", however, the text in the 'BUY MSR' column will not be updated. The 'BUY MSR' column displays the Buy Measure from each part's Buy Quantity Rule setup.

Purchase Order Grid

The Purchase Order grid displays the Purchase Order details. Fields that display are based on the pre-set layout format or the selected fields in the custom layout created/edited in the PO EDIT LAYOUT SETUP screen. The first nine fields always display regardless of the Edit Layout.

Displays the line code.

Displays the part number.

Displays the part cost from Price Level in the part table or the part cost from the ASN. Displays with custom field name if a custom field name is set up in the FIELD NAME SETUP screen.

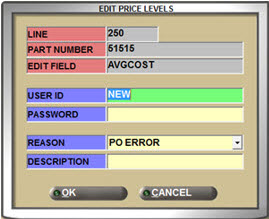

When any of the cost fields are edited, the 'EDIT PRICE LEVELS' pop-up displays and the edits are tracked to the Part Ledger Cost Edits Report.

Displays the core cost from the part table.

Displays the quantity ordered.

Displays the total in bound quantity from the ASN if an ASN has arrived.

Displays '0' (zero) unless the field is set to 'FULL ORDER QUANTITY' from the Set Recv Qty functionality or if the received quantity or 0 (zero) are manually entered. If the field is manually edited during PO receipt, ASN quantities are lost.

Displays the quantity that was posted as damaged during the receipt process.

Displays the quantity of the differences between what was ordered and what was received. A 'OVER' will display positive, and a 'SHORT' will display negative.

Displays the quantity that has been indicated as a 'CANCEL' on an ASN. Canceled quantities will not be shipped and will be canceled instead.

Displays '0' (zero) or the quantity for each part identified as a back order.

Automatically populates from the ASN and is not editable. A BACK ORDER is typically only sent with the ASN for parts where the quantity shipped is not equal to the quantity ordered; however, the vendor will be sending the balance on the ordered quantity on another ASN. When the PO is received, the quantity is put on a back order PO.

The 'BKO CANCEL' field on the ASN identifies back orders when set to a value other than 'C' (Cancel).

Totals Section

Indicates the total number of different parts included in the order.

TOTAL UNITS

Indicates the total quantity of parts ordered.

MINIMUM WEIGHT

Indicates the minimum weight identified when the PO was created. Some vendors want the order to be over a specific weight, so that value is entered in the 'MINIMUM WEIGHT' field at the time of PO creation.

If this threshold is used in PO creation, the total weight across all parts in the order must be equal to or greater than the default or overridden threshold amount to create the order.

TOTAL WEIGHT

Indicates the total weight of the items on the purchase order (On Ord * part Weight), if a 'MINIMUM WEIGHT' was entered at the time of PO creation.

If a 'MINIMUM WEIGHT' was entered, the system compares the 'TOTAL WEIGHT' to the 'MINIMUM WEIGHT' and, if less, then the 'TOTAL WEIGHT' displays in orange to alert the user.

TOTAL VOLUME

Indicates the total volume of the items on the purchase order, if a 'MINIMUM VOLUME' was entered at the time of PO creation.

If a 'MINIMUM VOLUME' was entered, the system compares the 'TOTAL VOLUME' to the 'MINIMUM VOLUME' and, if less, then the 'TOTAL VOLUME' displays in orange to alert the user.

MINIMUM VOLUME

Indicates the minimum volume identified when the PO was created. Some vendors want the order to be over a specific volume, so that value is entered in the 'MINIMUM VOLUME' field at the time of PO creation.

If this threshold is used in PO creation, the total volume across all parts in the order must be equal to or greater than the default or overridden threshold amount to create the order.

TOTAL COST

Indicates the total amount of the purchase order. If a 'MINIMUM ORDER COST' was entered at the time of PO creation, the system compares the 'TOTAL COST' to the 'MINIMUM ORDER COST' and, if less, then the 'TOTAL COST' displays in orange to alert the user.

MINIMUM COST

Indicates the minimum allowed total dollar value (cost) of the parts ordered using the ordered quantity and cost level specified in the Purchase Order Profile.

COST EXCH RATE

Indicates the cost exchange rate for the purchase order.

TOTAL EXCH COST

Indicates the total cost exchange rate for the purchase order.

On Order Quantities

The on order quantity is not reflected in the part file until the purchase order is finalized. However, other fields that are edited, such as cost, min, and max, affect the part file immediately regardless of PO status.

Battery Serial Number

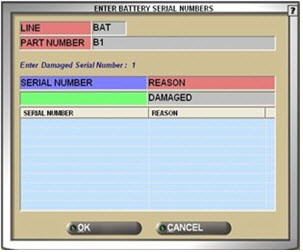

For batteries, a battery serial number must be tracked for the value designated as Overage, even though the quantity designated as an overage is received into stock with the ordered quantities. A battery serial number does not have to be entered for the originally ordered quantities.

For example, if three (3) batteries are ordered and five (5) are sent, the serial numbers from two (2) batteries must be entered.

Note: The Battery Serial Number is not tracked when the PO is auto-received.

If the 'TRACK BATTERY SERIAL NUMBERS' flag is checked in the SYSTEM PURCHASING SETUP screen, then when a part with the 'SUBTYPE' of 'BATT' is received with the reason code of 'DAMAGED' or 'OVERAGE', a window displays to enter each serial number of the parts designated as 'DAMAGED' or 'OVERAGE' as soon as the 'TRANSFER TO STOCK' button is clicked. The serial number must be entered for each damaged battery and when the last one is entered and the window is closed, a second window opens to enter the serial number for any overage batteries. If either window is closed before the correct serial numbers are entered, the system prompts that additional serial numbers must be entered.

Double-click a row to edit the row. Right-click to select 'DELETE' to delete a serial number.

The serial number is reported with the 'PO RECEIVING REPORT' under the 'OVER/SHORT/DAMAGED REPORT' section and historically from the PATI REPORT.

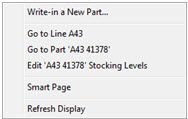

Right-Click Menu

Right-click on a highlighted part on the PURCHASE ORDER screen to display the following menu.

Smart Page

Click the Smart Page command to display a window with diagram and other details about the part, when available.

Menu Button

Click the 'MENU' button, or the arrow to the right of the menu, to expand the menu to display eight purchase order options. Click the 'MENU' button or arrow again to hide the menu options.

Place Order Button

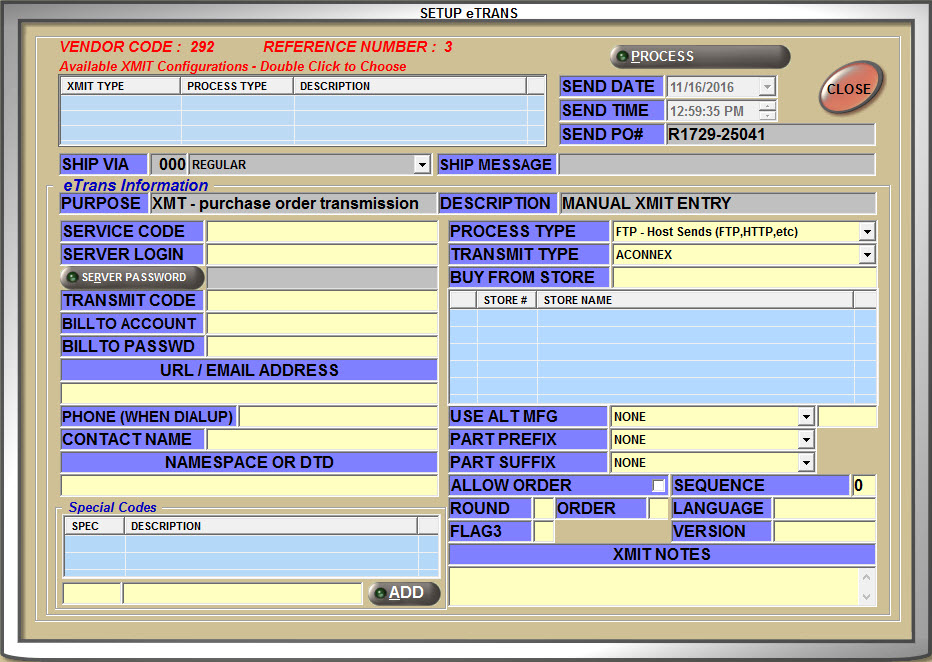

Click the 'PLACE ORDER' button from the menu list to transmit the PO to the vendor if transmission setups have been established for the vendor in the SUPPLIER XMIT SETUP screen. 'PLACE ORDER' can only be used once the PO has been finalized. If an XMIT record does not exist for the Vendor, the 'SETUP eTRANS' window displays to enter transmission information.

Displays the system-generated vendor code.

Displays the system-generated reference number.

Available XMIT Configurations Grid

Double-click to choose a configuration.

Indicates the shipping method.

SHIP METHOD

Displays a drop-down list of shipping methods to allow editing of the existing shipping method for the 'SERVING DC'. Ship methods are user-defined. Examples are 'DELIVERY', 'EXPEDITE', 'HOT SHOT', 'PICK UP', 'REGULAR', 'TRUCK', 'UPS/FED EX', and 'WILL CALL'. These are set up in the SYSTEM SOURCE SETUP screen. Defaults to 'SELECT'.

Overrides the value in the 'DEFAULT SHIP METHOD' field in the STORE GENERAL SETUP screen, 'SHELF SOURCING' tab.

SHIPPER #

Displays the shipper #. Field is enabled when a 'SHIP METHOD' is selected. Defaults to 'SELECT'. Click the button to display the 'BROWSE SHIPPER #S' window to assign a shipper # to a source.

Shipper #s are set up in the SYSTEM SOURCE SETUP screen, 'SHIP METHODS SETUP' tab.

SHIP MESSAGE

Indicates a ship message, if applicable. User-editable when a 'SHIP METHOD' or 'SHIPPER #' is selected.

SEND DATE

Indicates the send date.

SEND TIME

Indicates the send time.

SEND PO#

Indicates the purchase order number being sent.

eTrans Information

PURPOSE

Indicates the purpose of the transmission.

DESCRIPTION

Indicates a description for the supplier. Required to display the supplier on the sourcing grid.

SERVICE CODE

Indicates the Account # of the selling location.

SERVER LOGIN

Indicates the user's FTP User ID.

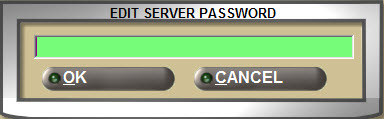

Indicates the user's FTP password.

Displays the 'EDIT SERVER PASSWORD' pop-up, when clicked, to enter the user's password.

Indicates the Location ID of the buyer that correlates to the 'BUY FROM STORE'.

BILL TO ACCOUNT

Indicates the account that is billed to the buyer.

BILL TO PASSWD

Indicates the Internet password of the account that is billed to the buyer.

URL / EMAIL ADDRESS

Indicates the Server IP address. Provided by PWS Customer Support.

PHONE (WHEN DIALUP)

Indicates the telephone number used to connect for dialup transmissions.

CONTACT NAME

Indicates the person to contact regarding the transmission.

NAMESPACE OR DTD

Specifies the correct formatting of all XML transmissions through AConneX. DTD (Document Type Definition)

PROCESS TYPE

Indicates the process types supported by PartsWatch and is dependent upon the specific type of transmission. All subsequent setups depend upon this selection.

TRANSMIT TYPE

Indicates the method of transmission. eTrans Information is dependent upon the 'TRANSMIT TYPE' and changes according to which 'TRANSMIT TYPE' is selected.

BUY FROM STATE

Indicates the store from which the user is buying from.

Indicates the alternate manufacturer, if applicable.

Options are:

- 'NONE'

- 'ALT 1 - 6' - Mfg Alt 1 code

- 'PRDT' - Part Product code

- 'GRP' - Part Group code

- 'MAST' - Mfg Master code

- 'USER' - manually enter

Indicates if a part prefix and/or part suffix is used.

Options are:

- 'NONE'

- 'PRDT' - Part Product Code

- 'GRP' - Part Group

- 'PNC' - Part Number Code

SEQUENCE

Indicates the specific sequence order that the program checks the source.

VERSION

Auto-populates with the AConneX version number when this is an AConneX setup.

XMIT NOTES

Displays user-entered comments about the supplier's transmit setup.

SPEC

Identifies the special code. These are also know an XMIT codes.

DESCRIPTION

Identifies the description of the special code.

ADD

Adds a special code, when clicked.

PROCESS

Processes the purchase order based on the setup.

When clicked and required setup values are blank for the vendor, a pop-up displays stating, "The <field name> cannot be blank. Enter the field value and click the PROCESS button to transmit the PO; or contact Support for assistance." The pop-up displays for each missing field until the order can be successfully transmitted.

Set Post Qty Button

Click the 'SET POST QTY' button from the menu list to display the 'EDIT PURCHASE ORDER' window.

Click 'FULL ORDER QUANTITY' when more parts from the PO are received than not received to set the received quantity for the entire order to the full order quantity. The amount in the 'POST' field automatically changes to the full amount of the order. Manually edit the received amount.

Click 'SET TO ZERO' when more parts from the PO are not received than are received to set the 'RCV' field to zero for all parts and manually enter the received quantity on the received items. The amount in the 'POST' field changes to zero and the field becomes editable. Manually enter the received amount.

Note: When selecting a Purchase Order in ASN status, and clicking the 'SET POST QTY' button in the PURCHASE ORDER screen, the first button on the pop-up is changed to allow the user to set the posted quantity based on the ASN quantity.

Click 'USE ASN SHIP QUANTITY' to set the receive quantity to the ship quantity indicated by the ASNs that were selected for this Purchase Order. The ASN quantity may be different from the 'INBOUND' quantity which is the ship quantity from all ASNs that were electronically applied to the Purchase Order, regardless of whether they were selected for this Purchase Order receipt session.

After the 'SET POST QTY' function is initiated and the 'FULL ORDER QUANTITY' is accepted, the quantities required for each store are applied and any extra part quantity ordered as a result of a buy quantity rule is assigned to the ordering (central buying) store.

When the 'EDIT PURCHASE ORDER' pop-up is launched, the extra quantity will be displayed in the 'POST' quantity for the ordering store.

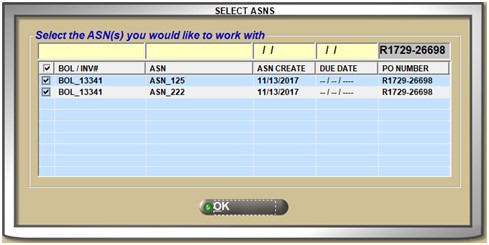

Selects ASNs

If the 'USE ASNS TO SET POST QUANTITY' option in the STORE PURCHASING SETUP, 'PURCHASING' tab screen is set to PROMPT, the SELECT ASNS pop-up is presented to the user when loading a Purchase Order in ASN status.

The fields at the top of the pop-up allow the user to optionally filter the list by 'BOL / INV #', 'ASN', 'ASN CREATE' date, 'DUE DATE', or 'PO NUMBER'.

To select no ASNs, uncheck all checkboxes and click 'OK'. The PURCHASE ORDER screen will display without any ASN detail being passed to that screen.

Post

Click the 'POST' button from the menu list to display the 'POST PO' window to post the order into stock and optionally print a 'POSTING REPORT'.

Posting Report

Reports posted purchase orders.

EXCLUDE AVG COST

Excludes reporting the average cost, when checked.

EXCLUDE PRICES

Excludes reporting the prices, when checked.

PRINT PO NOTE

Includes the PO Note, when checked.

POSTING REPORT

Prints the PO RECEIVING REPORT, when checked. Flag default is controlled by the value of the 'RECEIVING REPORT' flag in the SYSTEM PURCHASING SETUP screen, but can be edited at the time of printing.

NEGATIVE STOCK

Prints the 'NEGATIVE STOCK' section of the 'EXCEPTIONS REPORT', when checked. Flag default is controlled by the value of the 'NEGATIVE STOCK' flag in the SYSTEM PURCHASING SETUP screen, but can be edited at the time of printing.

SUPERSEDE/NIF

Prints the 'SUPERSEDE/NIF REPORT' section of the 'EXCEPTIONS REPORT', when checked. Flag default is controlled by the value of the 'SUPERSEDE/NIF' flag in the SYSTEM PURCHASING SETUP screen, but can be edited at the time of printing.

OVER/SHORT/DAMAGED

Prints the 'OVER/SHORT/DAMAGED REPORT' section of the 'EXCEPTIONS REPORT', when checked. Flag default is controlled by the value of the 'OVER/SHORT/DAMAGED' flag in the SYSTEM PURCHASING SETUP screen, but can be edited at the time of printing.

ADJUST/BACK ORDER

Prints the 'ADJUST/BACK ORDER REPORT' section of the 'EXCEPTIONS REPORT', when checked. Flag default is controlled by the value of the 'ADJUST/BACK ORDER' flag in the SYSTEM PURCHASING SETUP screen, but can be edited at the time of printing. Displays and is available only for purchase order lines received from Corporate. Only the parts on the PO that have Vendor Order Adjustments or Back Orders are reported.

PREVIEW

Generates a preview of the PO Receiving Report, when checked.

PRINTER

Sends the report to the printer, when checked.

NONE

Neither generates a report to preview nor sends to the printer, when checked.

Post PO

PUT THE DIFFERENCE ON BACKORDER

Puts the difference between the ordered quantity and received quantity on back order, when checked. If the 'SAVE BACKORDER' flag in the PURCHASE ORDER screen is checked, this flag is always checked and unavailable. If the 'SAVE BACKORDER' flag is unchecked, this flag is unchecked and unavailable.

TRANSFER TO STOCK

Transfers the received items to stock, optionally prints or previews available reports, puts any back ordered quantities on an 'OBK' PO, closes and removes the PO from the active list of POs in the 'PURCHASE ORDER MENU' and tracks the received quantities to PATI, when checked.

CLOSE

Closes the window.

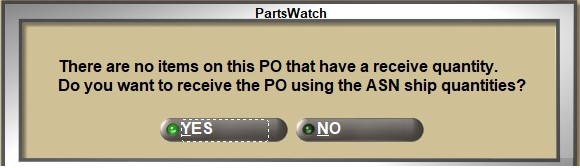

Post - ASNs Selected

When receiving a Purchase Order, regardless of how the received quantities had been set (whether by manually or automatically selecting an ASN, or setting the quantities manually) the Purchase Order will be received based on those quantities.

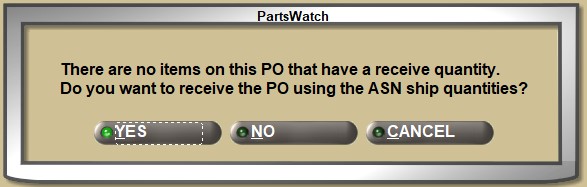

If ASNs were manually or automatically selected for a PO, but the user posts a PO in ASN status without first using 'SET RECV QTY', then upon clicking 'POST' one of the following pop-ups will display:

If 'SAVE BACKORDERS' is checked in the PURCHASE ORDER screen and there is a backorder quantity, the pop-up above displays.

- 'YES' - Will set the received quantity to the ASN ship quantity and receive the PO.

- 'NO' - Will receive the PO with zero quantity.

- 'CANCEL' - Will cancel the receive process and return to PURCHASE ORDER.

If 'SAVE BACKORDERS' is unchecked in the PURCHASE ORDER screen and there is no backorder quantity, the pop-up above displays.

- 'YES' - Will set the received quantity to the ASN ship quantity and receive the PO.

- 'NO' - Will cancel the receive process and return to the PURCHASE ORDER screen.

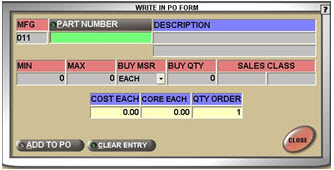

Write-In Part

Click the 'WRITE-IN PART' button from the menu list to display the 'WRITE IN PO FORM' window to add a write in part to the purchase order.

MFG

Displays the line code.

PART NUMBER

Indicates the part number. Click the button to display the 'FIND PART' window to select a part number.

DESCRIPTION

Displays the part number description.

MIN

Displays the minimum stocking level ('MIN') from the part table.

MAX

Displays the maximum stocking level ('MAX') from the part table.

BUY MSR

Displays how an item is packaged and sold: 'EACH', 'BARREL', 'CASE', 'DRUM', 'PACK', 'BOX', 'SKID', or 'ROLL'. Uses the 'BUY MEASURE' when a part has a buy quantity from the Buy Qty Rule.

BUY QTY

Indicates the 'BUY QTY' from the Buy Qty Rule.

SALES CLASS

Displays the Sales Class code from the part table (from both 1st and 2nd positions).

COST EACH

Displays the cost for each part.

CORE EACH

Displays the cost for each part core.

QTY ORDER

Displays the quantity being purchased. Defaults to '1'.

ADD TO PO

Adds the write-in part to the purchase order and clears the screen.

CLEAR ENTRY

Clears the entered information from the window. A message displays asking "Are you sure?"

CLOSE

Closes the window.

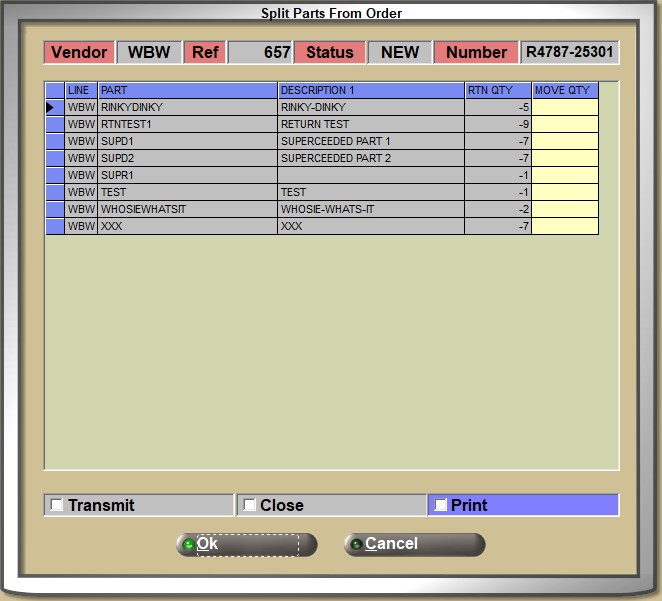

Split Parts From Order

Clicking the 'SPLIT' button opens the 'Split Parts From Order' pop-up, see example below:

Vendor

Displays the vendor that the selected parts are being returned to.

Ref

Displays the reference number for the order that the parts were a part of.

Status

Displays the status of the order that the parts were included in.

Number

Displays the order number for the selected parts that are being split.

LINE

Displays the Line Code for the selected parts to be split.

PART

Displays the Part Number for the selected parts to be split.

DESCRIPTION 1

Displays the value from the 'DESCRIPTION 1' field from the MAIN PART ENTRY screen for the selected parts to be split.

RTN QTY

Displays the quantity to be returned for the selected parts being split.

MOVE QTY

The 'MOVE QTY' textbox auto-populates with the value of the 'RTN QTY' to enable the moving the entire 'RTN QTY' amount, or edit that amount to a lesser amount.

Any value above 0 in this textbox indicates that the part will be split and will participate in the move.

Transmit

When checked, electronically transmits the new return order to the selected vendor.

When unchecked, does not transmit the new return order.

This checkbox is disabled if there is no XMIT record for this vendor.

Close

When checked, closes the return order.

When unchecked, does not automatically close the return order.

Print

When checked, prints a return order report for the new return order.

When unchecked, does not print a return order report for the new return order.

Ok

When the 'Ok' button, a new return order is created, the chosen parts are split from the original return order to the new return order, the return order is finalized, the "post-splitting" actions are performed based on the user's choices for 'Transmit', 'Close', or 'Print', a pop-up displays indicating the success of the split, and the system returns to the PURCHASING DASHBOARD screen.

Cancel

When the 'Cancel' button, a new return order is not created, no parts are split from the original return order, no "post-splitting" actions such as 'Transmit', 'Close', or 'Print' are performed, and the system returns to the PURCHASING DASHBOARD screen.

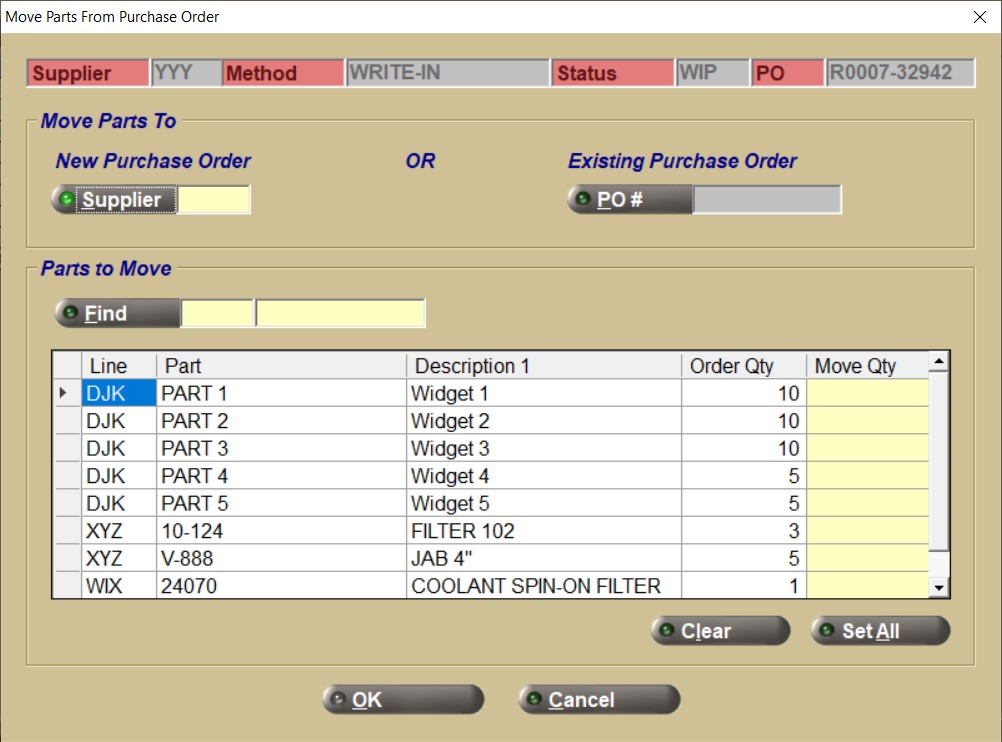

Move Parts from Purchase Order

This pop-up allows for the Move function, so that some or all parts from an existing purchase order can be moved to a new or existing purchase order.

-

The 'SOURCE' of the original purchase order can only be 'SHELF'.

-

The original purchase order can be in any status prior to moving any parts. However, the PO must be in an editable state in order to move parts.

-

The destination PO, if existing, can be in any status. However, the destination PO must be in an editable state in order to accept moved parts.

-

If parts are moved to a new PO, that PO should be in 'WIP' status.

-

The destination PO can be for the same or different supplier.

-

If 100% of the Order Qty of a part is moved from one PO to another, the part is removed from the original PO (since its Order Qty is now zero).

-

-

Parts with remaining Order Qty > 0 remain on the original PO.

-

If 100% of the Order Qty of all parts are moved from one PO to another, the entire original PO is deleted.

-

There is no validation that the destination PO supplier actually supports the parts that are moved to their PO.

-

If the supplier's minimum thresholds on the destination PO are not met, the purchase order will not be created.

-

Moving parts from one PO to another could result in the originating PO no longer meeting supplier thresholds. If so, these will be highlighted in orange on the original PO as per existing functionality.

-

If the supplier has a Buy Quantity Rule, the move quantity on the destination PO will be adjusted accordingly to meet that BQR.

-

If a part attempting to be moved has any on order quantity for a customer backorder, no quantity of that part can be moved. The move is denied and a message prompt displayed with the text: "You may not move a part ordered for automatic back order filling. Part <Line> <PN> has been ordered for a customer back order." with an 'OK' button to clear the message.

Multi-Store Purchase Orders are handled differently:

-

When the source PO is a multi-store purchase order and a new purchase order is selected as the destination PO, the destination purchase order should be a single store purchase order. It should use the central buying store for the new order.

-

When moving parts to an existing destination PO that is a multi-store distributed order, all order quantity is placed in the central buying store for all parts moved. Users can redistribute quantities across stores after the move is complete using existing functionality.

-

When the source PO is a multi-store distributed order:

-

If 100% of the order quantity of a part is moved, the order quantity of the part on the source PO is set to zero and it is removed from all stores on the original order.

-

If <100% of the order quantity of a part is moved, the application reduces the order quantity by 1 unit from each child store order quantity of the part in a ‘round-robin’ manner until the move quantity is satisfied.

-

If <100% of the order quantity of a part is moved, and the part is ordered using a buy quantity rule, and the move quantity is greater than or equal to the sum of all of the child store order quantities but is less than the total order quantity of a part (due to rounding up for BQR) the requested move quantity is moved to the destination purchase order and the order quantity for the part on the source purchase order is set to zero.

-

-

If the PO is created and then part quantities are moved to another PO for the same vendor and the move quantity is, for example 6 or less, the destination PO will have an order quantity of 8, to meet the BQR, and the order quantities on the original PO will be set to zero, since it no longer supports the part’s BQR.

Supplier

Displays the supplier code for the PO that was selected.

Method

Displays the method for the current PO (for example, Write-In)

Status

Displays the status of the current PO.

PO

Displays the existing PO #.

Move Parts To

Identifies the destination PO for the move.

New Purchase Order

Supplier

Used when a new purchase order is desired to move the parts to. Click the 'Supplier' button to open the 'Browse Suppliers' pop-up to make a selection. Otherwise the Supplier code must be typed into the text box directly and the 'Enter' key must be pressed to accept the entry.

Existing Purchase Order

PO #

Used when an existing purchase order is desired to move the parts to.

Click the 'PO #' button to open the 'Browse Purchase Orders' pop-up to make a selection.

Parts to Move

Identifies the parts to be moved and their quantities.

Find

Searches the list of parts on the order. When clicked, the 'Find Part' pop-up displays allowing for selection from all parts.

If the selected part is found, the row is made visible (if it wasn't already) and the system highlights the 'Move Qty' cell. Enter a quantity in this field.

If the selected part is not on the purchase order, the system issues a message prompt with the text: "<part number> was not found on the purchase order." and an 'OK' button to clear the pop-up.

Grid

If a cell in the grid is clicked, the row is considered selected. A triangle icon appears in the first column of that row to indicate the selection.

If a column heading in the grid is clicked, sort the grid alphanumerically by that column in ascending order. If the same column heading is clicked again, reverse the sort. In both cases, display an up or down triangle in the column heading adjacent to the heading text to indicate by which column the grid is sorted and in what order.

Line

Displays the line of the part.

Part

Displays the part number of the part.

Description 1

Displays the description of the part.

Order Qty

Displays the amount of units on the current purchase order.

Move Qty

Displays the amount of units to be moved to the destination purchase order. The ‘Move Qty’ column is yellow to indicate it is editable.

Cells in the 'Move Qty' column:

- Accept numeric values only. If a non-numeric character is entered, issue a message prompt with the text: "Invalid entry. Numeric required!" and an 'OK' button to clear the pop-up.

- Accept quantities from 1 to the amount in the adjacent 'Order Qty' field. For instance, if the 'Order Qty' is 10 and 11 is entered, issue a message prompt with the text: "The value must be between 1 and 10." and an 'OK' button to clear the pop-up.

- If 0 is entered it is cleared by the application.

Clear

Removes all entries from the 'Move Qty' column.

Set All

Copies all values in the 'Order Qty' column to the 'Move Qty' column. Users may continue to edit quantities in the 'Move Qty' column.

OK

Processes the move request.

If the request is processed successfully, the system issues a message prompt with the text: "N parts moved to order <PO_number>." and an 'OK' button to clears the pop–up.

Cancel

Closes the pop-up and does not move any parts.

Move Parts from Another PO

To move parts from another purchase order, follow the steps below:

-

When the purchase order to be moved is displayed in the PURCHASE ORDER screen and the 'MOVE' button is clicked, the application opens a new pop-up, 'Move Parts From Purchase Order'.

-

Decide whether you would like to:

-

Move parts to a new purchase order for the same or different supplier,

-

Or, move parts to an existing purchase order for the same or different supplier.

-

-

To move parts to a new purchase order, type in the supplier code next to the 'Supplier' lookup button, or click the 'Supplier' lookup button to select the supplier from the supplier list.

-

Note: If the new purchase order is for the same supplier, it must be still selected/entered in this field.

-

The resulting new purchase order will be in 'WIP' status and have a method of 'Write-In'.

-

-

To move parts to an existing purchase order, the user should click the ‘PO#’ lookup button to display the ‘Browse Purchase Orders’ pop-up.

-

The list may be filtered using any of the yellow fields adjacent to the column headings.

-

All open purchase orders should be displayed.

-

The destination purchase order must be in an editable state. If it is not and has already been transmitted and is selected, issue a message prompt with the text: "This PO has been transmitted to the vendor." and an 'OK' button to clear the pop-up.

-

The destination purchase order will retain its status (e.g. 'FIN') and its method (e.g. 'MAX').

-

-

Next, specify the part(s) to be moved to the destination purchase order by entering a value in the 'Move Qty' field. One, multiple or all parts may be moved.

-

Parts displayed in the grid include all parts from the selected purchase order where the 'Ord Qty' is greater than zero and the 'INBOUND QTY' equals zero.

-

Optionally edit the 'Move Qty' amount to any amount between one and less than or equal to the value in the 'Order Qty' field.

-

If the 'Move Qty' amount is set to a value between 1 and the value equal to the 'Ord Qty', move the part and 'Ord Qty' to the destination purchase order and decrease the 'Ord Qty' for the part on this purchase order by the 'Move Qty' amount.

-

For example, if the 'Ord Qty' is 28 and the 'Move Qty' is 8, the destination 'Ord Qty' will be 8 for the part and the 'Ord Qty' on the source PO will be updated to 20.

-

-

If the 'Move Qty' amount is set equal to the value in the 'Ord Qty' field, the part will be moved to the destination purchase order and removed entirely from this (the source) purchase order.

-

If the 'Move Qty' amount is set to a value greater than the current 'Ord Qty', a message prompt will be displayed.

-

-

Once parts and quantities are selected, click 'OK'.

-

If successful, a confirmation message prompt appears with the text: "<x> parts moved to order <purchase_order_number>." Click 'OK' to clear the message.

-

The screen should refresh and display destination PO in the PURCHASE ORDER screen.

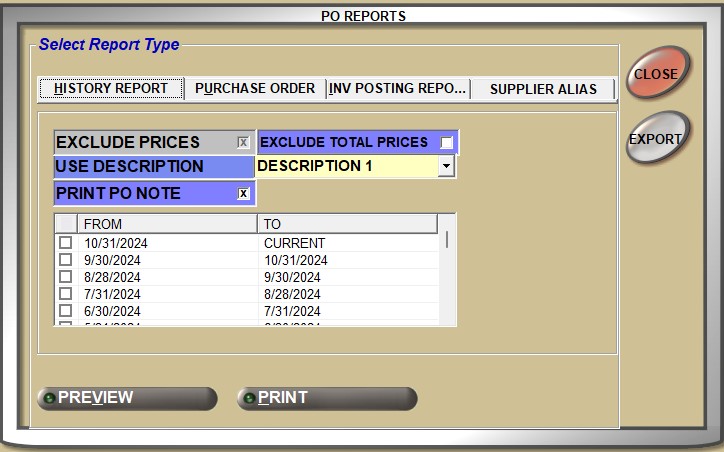

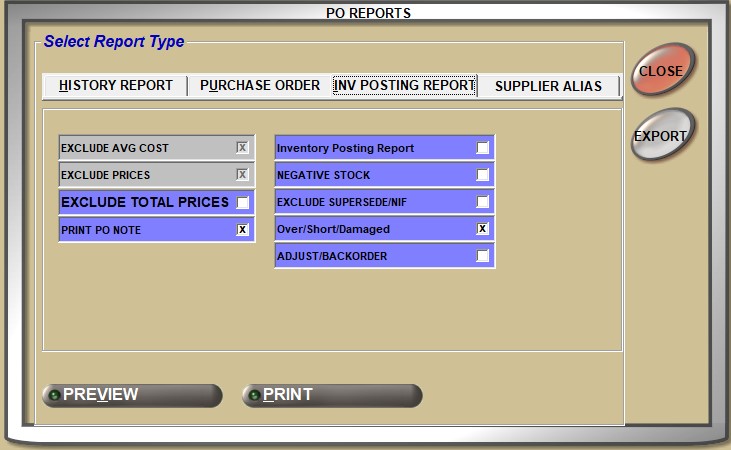

Reports

Click the 'REPORTS' button from the menu list to display the 'PO REPORTS' window. Click 'HISTORY REPORT', 'PURCHASE ORDER', 'INV POSTING REPORT', or 'SUPPLIER ALIAS'.

History Report

Reports historical purchase orders based on the selected criteria.

EXCLUDE PRICES

Excludes reporting the prices on the report, when checked.

EXCLUDE TOTAL PRICES

Determines whether or not the pricing totals are displayed on the report.

- Checked - The 'PO COST TOTAL $' label and amount are hidden from the 'PO TOTALS' box at the bottom of the report.

- Unchecked (default) - Does not hide any totals on the report.

Note: If the 'EXCLUDE PRICES' checkbox is checked, the entire 'EXT COST $' column is hidden, including the grand total of that column. If the 'EXCLUDE PRICES' checkbox is unchecked, and the 'EXCLUDE TOTAL PRICES' checkbox is checked, only the grand totals are hidden.

Note: If the security proc 'PO COST TOTALS' is set to 'NOT VISIBLE', the setting for the 'EXCLUDE TOTAL PRICES' checkbox is ignored.

PRINT PO NOTE

Includes the PO Note, when checked.

USE DESCRIPTION

Includes the selected description, 'Description 1' or 'Description 2'.

Grid

[Checkbox]

Identifies the date(s) to include in the report, when checked.

FROM

Indicates the invoice date to start with when printing the report.

TO

Indicates the invoice date to end with when printing the report.

PREVIEW

Displays a preview of the system-generated report.

PRINT

Prints a hard copy of the report.

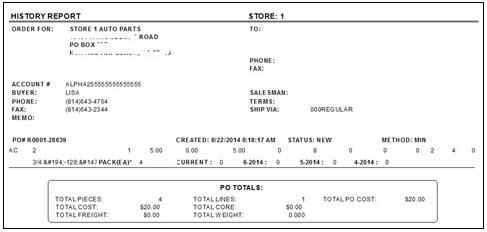

The following is an example of the 'HISTORY REPORT':

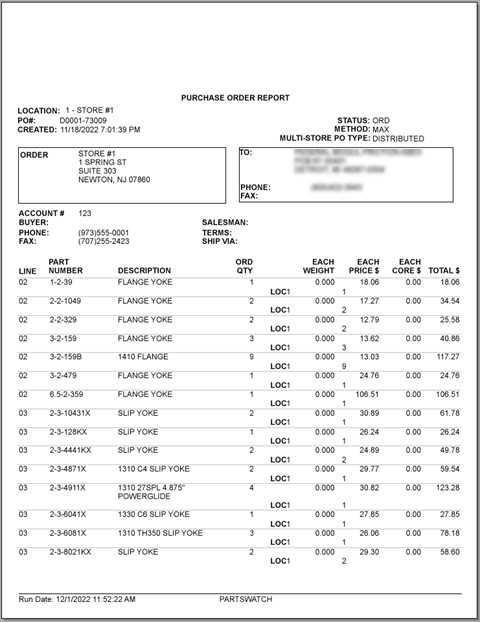

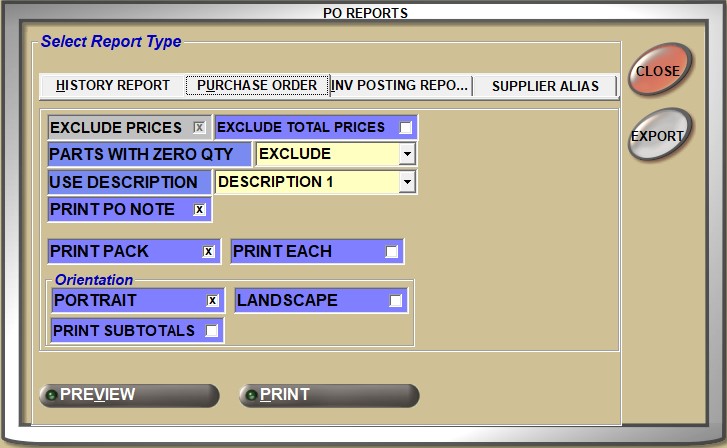

Purchase Order Report

Reports purchase orders.

EXCLUDE PRICES

Excludes reporting the prices, when checked.

EXCLUDE TOTAL PRICES

Determines whether or not the pricing totals are displayed on the report.

- Checked - The 'GRAND TOTAL' amount for the 'TOTAL $' column is hidden and the 'PO COST TOTAL $' label and amount are hidden in the totals box at the bottom of the report.

- Unchecked (default) – Does not hide any totals on the report.

Note: If the 'EXCLUDE PRICES' checkbox is checked, the entire 'EXT COST $' column is hidden, including the grand total of that column. If the 'EXCLUDE PRICES' checkbox is unchecked, and the 'EXCLUDE TOTAL PRICES' checkbox is checked, only the grand totals are hidden.

Note: If the security proc 'PO COST TOTALS' is set to 'NOT VISIBLE', the setting for the 'EXCLUDE TOTAL PRICES' checkbox is ignored.

PARTS WITH ZERO QTY

Determines whether parts with zero quantities ordered on a non-finalized purchase order display on the Purchase Order Report.

Options are:

- 'EXCLUDE' (Default) - Excludes parts where the quantity ordered has been zeroed out on the Purchase Order Report.

- 'INCLUDE' - Includes parts where the quantity ordered was zeroed out on the Purchase Order Report.

- 'ONLY' - Only reports parts where the quantity ordered has been zeroed out on the Purchase Order Report.

Displays for a purchase order that has not yet been finalized only. Does not display when purchase order has been finalized. Finalized purchase orders always exclude parts with zero quantities.

USE DESCRIPTION

Includes the selected description, 'Description 1' or 'Description 2'.

PRINT PO NOTE

Includes the PO Note, when checked.

PRINT SOURCED PO VENDOR NOTE

Includes the Sourced Purchase Order Vendor note, when checked. (Default is unchecked).

PRINT PACK

Reports the 'BUY MEASURE' and 'BUY QTY' (for parts with a Buy Quantity Rule) in the 'MEAS' field, when checked. For example: *EA (2) for parts with a 'BUY QTY' of 2 and a 'BUY MEASURE' of 'EA'. Either the 'PRINT PACK' or 'PRINT EACH' flag can be checked. Defaults to 'PRINT PACK'.

PRINT EACH

Does not report the 'MEAS' field and reports the Each quantity but shows an asterisk (*) that a BQR exists.

Orientation

PORTRAIT

Outputs the Purchase Order Report in portrait orientation. (Default)

LANDSCAPE

Outputs the Purchase Order Report in landscape orientation.

PRINT SUBTOTALS

Outputs the Purchase Order Report with Subtotals and is totaled at the end in the 'GRAND TOTAL', when checked.

Outputs the Purchase Order Report without Subtotals and is totaled at the end in the 'GRAND TOTAL' only, when unchecked. (Default)

Available only when the 'PORTRAIT' field is checked.

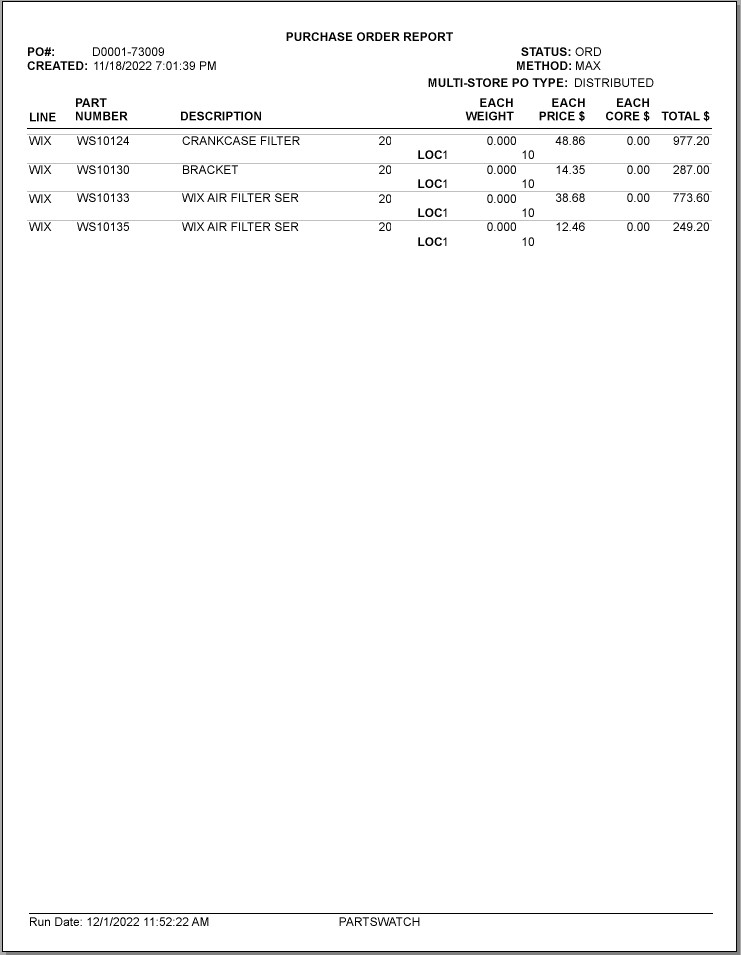

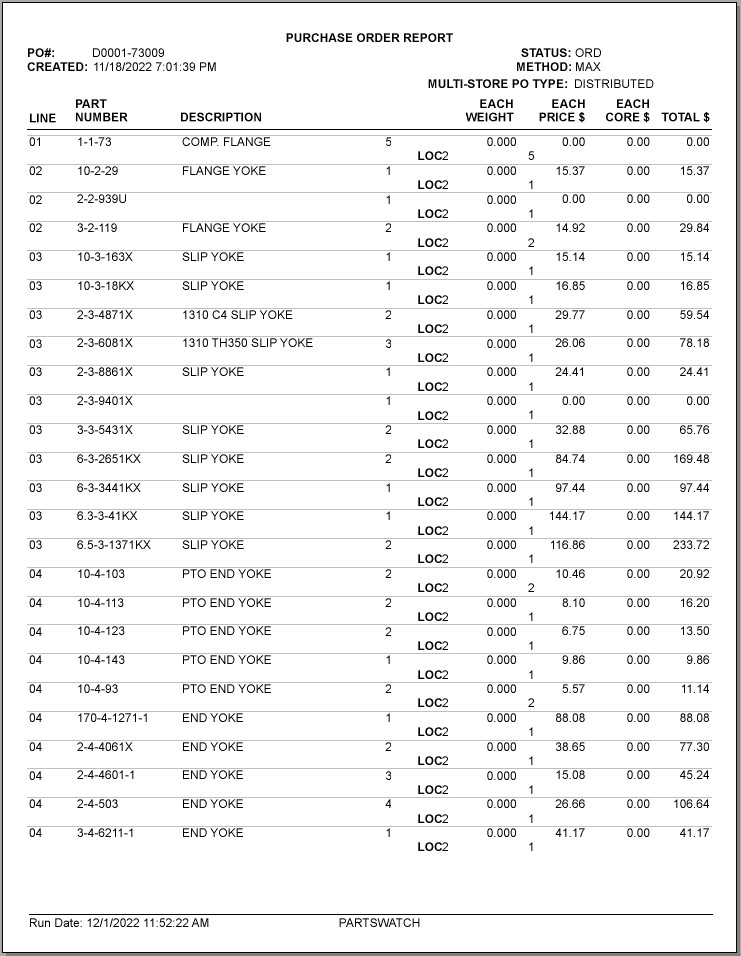

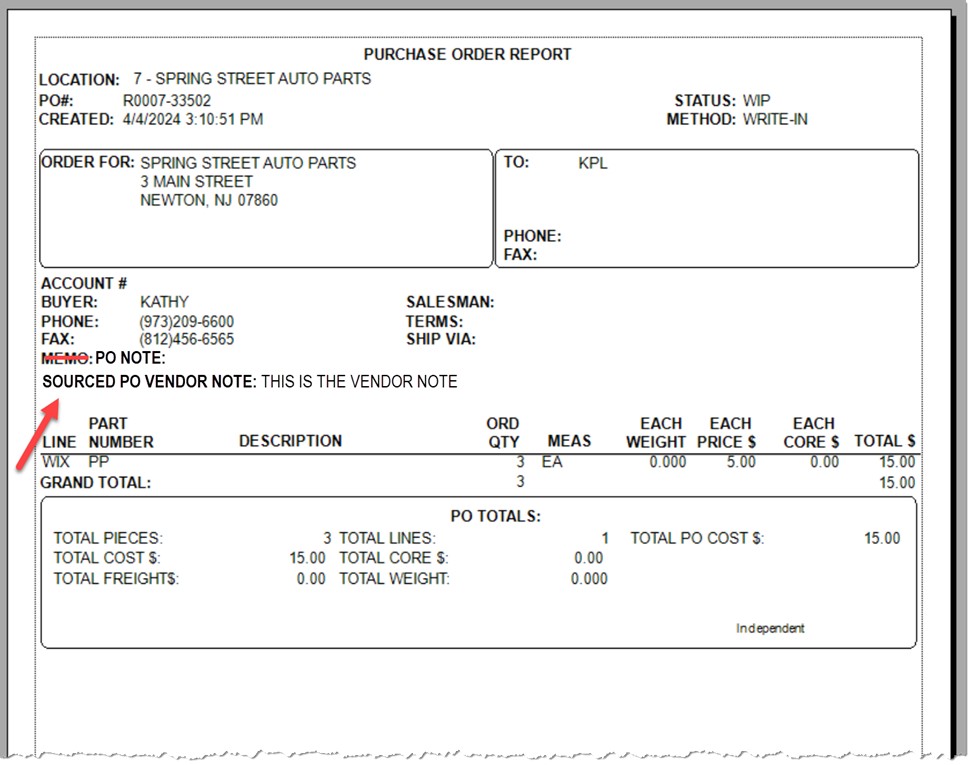

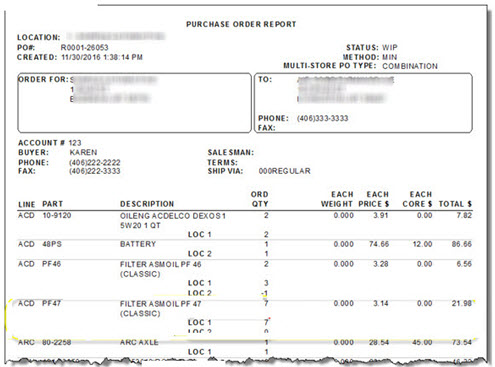

The following is an example of the 'PURCHASE ORDER REPORT' with 'PRINT SUBTOTALS' checked, and with the 'PRINT PO NOTE' and 'PRINT SOURCED PO VENDOR NOTE' checkboxes checked:

Inventory Posting Report

Reports posted purchase orders.

EXCLUDE AVG COST

Excludes reporting the average cost, when checked.

EXCLUDE PRICES

Excludes reporting the prices, when checked.

EXCLUDE TOTAL PRICES

Determines whether or not the pricing totals are displayed on the report.

- Checked - the 'EXT COST $' grand totals are hidden and the 'TOTAL PO COST $' is hidden from the summary box at the bottom of the report.

- Unchecked (default) - Does not hide any totals on the report.

Note: If the 'EXCLUDE PRICES' checkbox is checked, the entire 'EXT COST $' column is hidden, including the grand total of that column. If the 'EXCLUDE PRICES' checkbox is unchecked, and the 'EXCLUDE TOTAL PRICES' checkbox is checked, only the grand totals are hidden.

Note: If the security proc 'PO COST TOTALS' is set to 'NOT VISIBLE', the setting for the 'EXCLUDE TOTAL PRICES' checkbox is ignored.

PRINT PO NOTE

Includes the PO Note, when checked.

RECEIVING REPORT

Prints the 'PO POSTING REPORT', when checked. Flag default is controlled by the value of the 'POSTING REPORT' flag in the SYSTEM PURCHASING SETUP screen, but can be edited at the time of printing.

NEGATIVE STOCK

Prints the 'NEGATIVE STOCK' section of the 'EXCEPTIONS REPORT', when checked. Flag default is controlled by the value of the 'NEGATIVE STOCK' flag in the SYSTEM PURCHASING SETUP screen, but can be edited at the time of printing.

SUPERSEDE/NIF

Prints the 'SUPERSEDE/NIF REPORT' section of the 'EXCEPTIONS REPORT', when checked. Flag default is controlled by the value of the 'SUPERSEDE/NIF' flag in the SYSTEM PURCHASING SETUP screen, but can be edited at the time of printing.

OVER/SHORT/DAMAGED

Prints the 'OVER/SHORT/DAMAGED REPORT' section of the 'EXCEPTIONS REPORT', when checked. Flag default is controlled by the value of the 'OVER/SHORT/DAMAGED' flag in the SYSTEM PURCHASING SETUP screen, but can be edited at the time of printing.

ADJUST/BACK ORDER

Prints the 'ADJUST / BACK ORDER REPORT' section of the 'EXCEPTIONS REPORT', when checked. Flag default is controlled by the value of the 'ADJUST/BACK ORDER' flag in the SYSTEM PURCHASING SETUP screen, but can be edited at the time of printing.

Note: A Vendor Order Adjustment is a communication sent by Corporate that adjusts order quantities either up or down without impacting inbound. There are several types of vendor order adjustments. A negative adjustment would be sent for a part that has been ordered by the store, but cannot be delivered for some reason. A positive adjustment could be sent for a corporate-created order on behalf of the store to increase order quantities due to minimum or pack quantities, or other reasons.

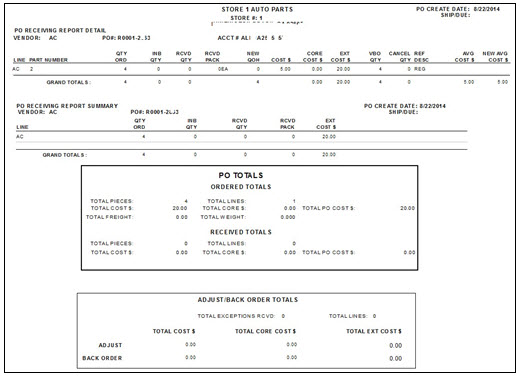

The following is an example of the 'INVENTORY POSTING REPORT'.

The example includes the 'ADJUST/BACK ORDER REPORT' section. When more than one Vendor Order Adjustment is sent on the ASN for the same part on the same PO, the 'ADJUST/BACK ORDER REPORT' displays each 'ADJ Qty' / 'ADJ Code' on a separate row. Only the 'LINE' and 'PART NUMBER' print for all rows.

Note: The application determines if a part is from a Ghost Order based on the expected arrival date sent on the ASN. When a part is not received within a predetermined number of days after the expected date of arrival, the part is flagged as Ghost Order ('Y' for 'YES'). The default number of days is 30. When the part has been received, the field is blank (for 'NO'). If the 'EXP ARRIVE DATE' field is blank, the 'GHOST ORDER' field is blank.

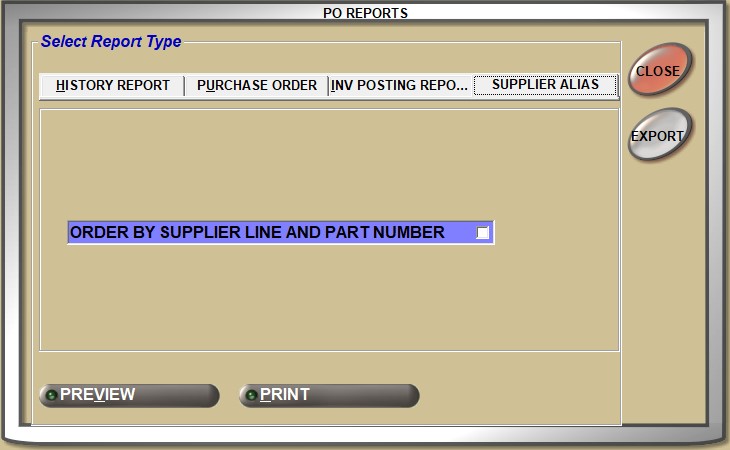

Supplier Alias Report

Reports purchase order for buy or return with changes for supplier alias.

EXCLUDE PRICES

Excludes reporting the prices, when checked.

PARTS WITH ZERO QTY

Determines whether parts with zero quantities ordered on a non-finalized purchase order display on the Purchase Order Report.

Options are:

- 'EXCLUDE' (Default) - Excludes parts where the quantity ordered has been zeroed out on the Purchase Order Report.

- 'INCLUDE' - Includes parts where the quantity ordered was zeroed out on the Purchase Order Report.

- 'ONLY' - Only reports parts where the quantity ordered has been zeroed out on the Purchase Order Report.

Displays for a purchase order that has not yet been finalized only. Does not display when purchase order has been finalized. Finalized purchase orders always exclude parts with zero quantities.

USE DESCRIPTION

Includes the selected description, 'Description 1' or 'Description 2'.

PRINT PO NOTE

Includes the PO Note, when checked.

PRINT PACK

Reports the 'BUY MEASURE' and 'BUY QTY' (for parts with a Buy Quantity Rule) in the 'MEAS' field, when checked. For example: *EA (2) for parts with a 'BUY QTY' of 2 and a 'BUY MEASURE' of 'EA'. Either the 'PRINT PACK' or 'PRINT EACH' flag can be checked. Defaults to 'PRINT PACK'.

PRINT EACH

Does not report the 'MEAS' field and reports the 'Each' quantity but shows an asterisk (*) that a BQR exists.

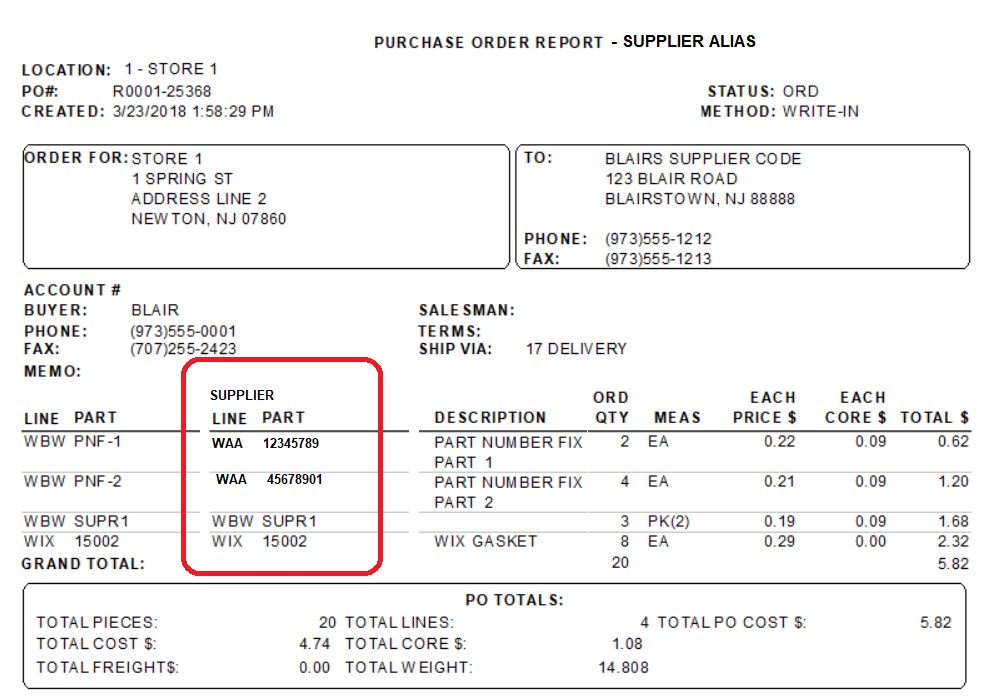

The following is an example of the 'PURCHASE ORDER REPORT - SUPPLIER ALIAS'.

Multi-Store Report

Reports Purchase Order details for multi-store "combination" POs.

SORT BY

Reports PO details by specified sort.

Options are:

- 'LINE / PART' - Sorts items by Line and Part, and within each part shows a total 'ORD QTY' and quantities for each store.

- 'STORE' - First sorts all parts by Store/Location number, then by Line, and then by Part Number.

SHOW 0 ORDERED STORES

Determines if parts are reported for a store even if user zeroed order quantity.

Options are:

- 'EXCLUDE' - Excludes part for a store if user zeroed order quantity for that store.

- 'INCLUDE' - Includes parts for a store even if user zeroed order quantity for that store, along with parts/stores that had a quantity.

- 'ONLY' - Only reports parts for which user zeroed order quantity.

The following is an example of the Multi Store 'PURCHASE ORDER REPORT – MULTI-STORE PO TYPE: COMBINATION'.

Note: 'COMBINATION' indicates that the 'AUTOMATICALLY DISTRIBUTE MULTISTORE ORDERS' flag is checked in the STORE PURCHASING SETUP screen, 'PURCHASING' tab.

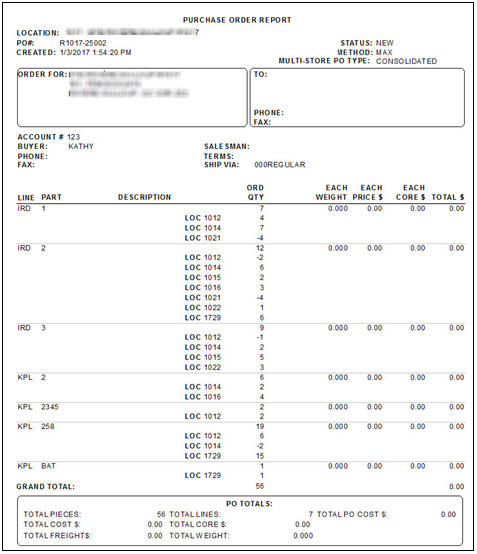

The following is an example of the Multi Store 'PURCHASE ORDER REPORT – MULTI-STORE PO TYPE: CONSOLIDATED'.

Note: 'CONSOLIDATED' indicates that the 'AUTOMATICALLY DISTRIBUTE MULTISTORE ORDERS' flag is unchecked in the STORE PURCHASING SETUP screen, 'PURCHASING' tab.

The 'GRAND TOTAL' includes the 'ORD QTY' for all items, whether reported or not due to filtering.

The 'PO TOTALS' section includes totals for items/stores included on the report.

PO Info

Click the 'PO INFO' button from the menu list to display the 'PURCHASE ORDER INFORMATION' and 'VENDOR INFORMATION' for the current PO.

Only the 'FREIGHT', 'SHIP/DUE', 'SHIP METHOD', and 'SHIPPER #' fields are editable, as long as the order has not yet been transmitted. The 'SHIPPER #' field is enabled when a Ship Method is selected in the 'SHIP METHOD' field. By default, Line Code orders display a 'SHIP CODE' of 'REGULAR' and a 'SHIPPER #' of '000'. By default, Supplier orders display the Ship Method and Shipper # set up in 'SHIP METHOD' and 'SHIPPER #' fields in the SUPPLIER ORDER SPECIFICS screen. If no 'SHIP METHOD' or 'SHIPPER #' is set up, the 'SHIP METHOD' defaults to 'REGULAR' and the 'SHIPPER #' defaults to '000'. Note: WRITE-IN POs default to blank for both Line and Suppliers.

When the supplier has a record set up in the SYSTEM SOURCE SETUP screen, 'VENDOR SOURCE SETUP' tab, the 'SHIP METHOD' and 'SHIPPER #' displays as a combined 'SHIP METHOD/SHIPPER #' drop-down. The drop-down displays each 'SHIPPER #' followed by a dash and then the 'SHIP METHOD'. This 'SHIPPER #' is used for order transmission by default. Defaults to blank.

If a combined 'SHIP METHOD / SHIPPER #' is specified for a supplier, and later that combination is deleted from the SYSTEM SOURCE SETUP screen, 'VENDOR SOURCE SETUP' tab, the same Ship Method and Shipper # is retained in the supplier record, but as separate fields, and shows in PO Info as separate fields.

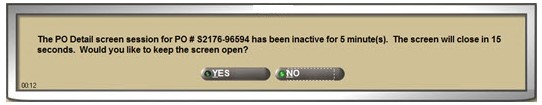

Locked PO

When PO detail screen is open on a user's screen, the PO is considered "locked" and cannot be accessed by another user until closed.

The 'PO DETAIL SCREEN INACTIVITY MINUTES' field in the SYSTEM PURCHASING SETUP screen enables the you to set the number of minutes that a PO can remain open on a user's screen and inactive before being automatically closed. When a PO is left open beyond the pre-set time, a pop-up displays to inform when the PO will close. Close the PO or keep the PO open. Once closed, the PO is available for another user to open.

If an ASN attempts to apply to a PO and the PO is locked, the ASN is not able to apply to the PO. By default, it attempts to re-apply for 24 hours. This default can be changed by PWS Support. If the number of retries exceeds the time limit, a message is recorded to the SYSTEM MESSAGES screen, and application of the ASN is canceled.