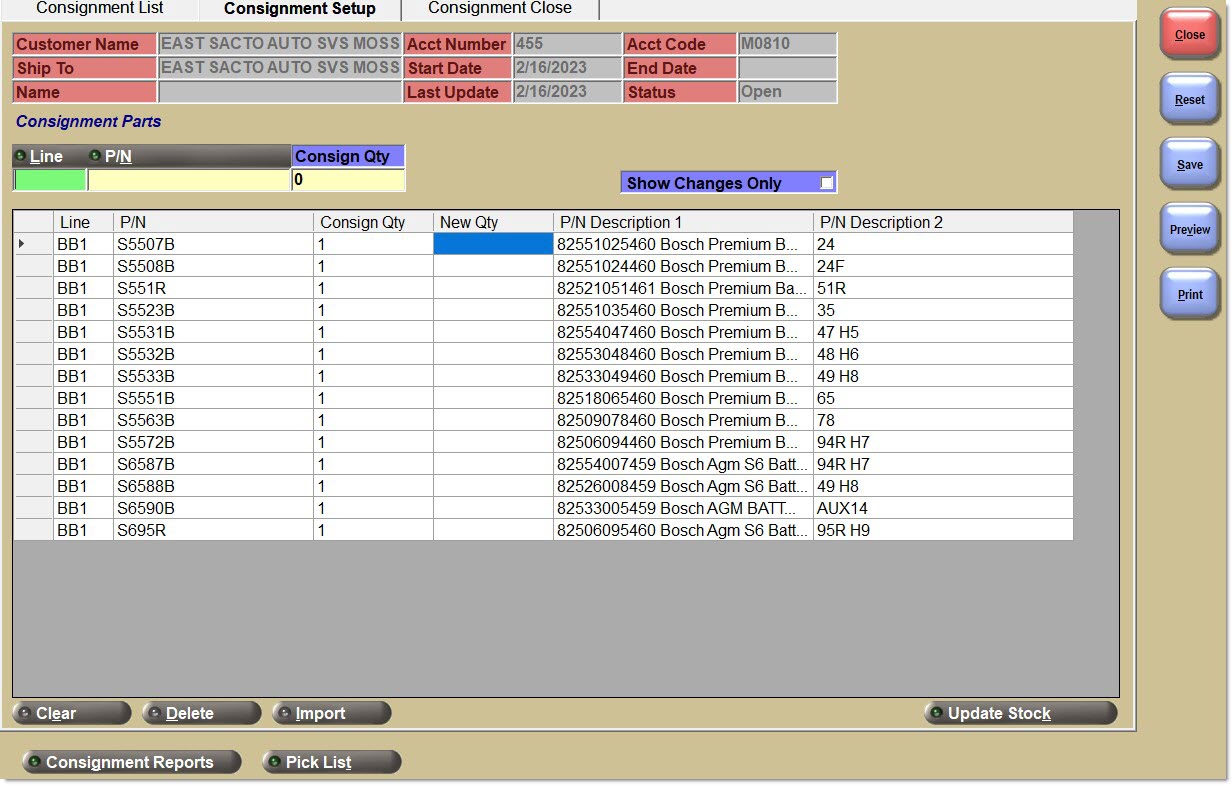

Consignment Setup Tab

The Consignments Setup screen is used to add, edit and close consignments. The Consignments Setup screen has three tabs:

Menu Path: Customer, Consignments Setup, Consignment Setup screen

The 'Consignment Setup' tab is used to set up the parts that will be on consignment per customer.

Highlighting a consignment on the 'Consignment List' tab and clicking the 'Consignment Close' tab will open the tab with that consignment in focus.

Customer Name

Displays the name of the customer for which the consignment is being set up. For information only.

Ship To

Displays the ship to address of the customer for which the consignment is being set up. For information only.

Acct Number

Displays the account number of the customer for which the consignment is being set up. For information only.

Acct Code

Displays the account code of the customer for which the consignment is being set up. For information only. Only displays if there is an account code set up for the customer.

Start Date

Remains blank until the 'Update Stock' button is clicked and the open consignment process is complete. Displays the start date for the consignment. For information only.

End Date

Remains blank until the 'Update Stock' button is clicked and the close consignment process is complete. Displays the end date for the consignment. For information only.

Last Update

Displays the date the consignment was added. This field is updated every time the consignment is edited.

Displays the status of the consignment.

Options are:

-

'Draft' - The new consignments have been saved, but stock quantity has not yet been adjusted.

-

'Open' - Stock quantity has been adjusted by parts on the consignment.

-

'Closed' - The consignment has been closed and stock quantity has been adjusted.

Search and select a line code from the 'Browse Line Codes'.

Search and select a part number from the 'Find Part' window.

Consign Qty

Field used to set up the consignment quantity that will be included in the consignment per part.

Show Changes Only

When checked, the grid will refresh and display only those parts that have a value in the 'New' column.

When unchecked, all parts will display (default).

Note: The field is not used to determine the parts reported when the 'Print' or 'Preview' button is clicked.

Clicking any of the column headers will sort the items by that field.

Line

Displays the Line Code that was set up in the data entry field above the grid.

P/N

Displays the Part Number that was set up in the data entry field above the grid.

Consign Qty

Displays the value from the 'New Qty' field when the 'Update Stock' button is clicked so that the stock quantity is adjusted for the consignment.

New Qty

Displays the value from the 'Consign Qty' field when new parts are added to the grid.

Also used to edit the consignment quantity.

Note: The system does not validate that the entered quantity exists in stock when added to the consignment.

P/N Description 1

Displays the 'Description 1' from the part table when the set up was moved from the data entry row to the grid. For information only.

P/N Description 2

Displays the 'Description 2' from the part table when the set up was moved from the data entry row to the grid. For information only.

Clear

When clicked, the system will open a prompt asking to clear the grid.

'Yes' clears all parts in the grid.

'No' aborts clearing the parts.

Note: This button is available in draft mode only.

Delete

When clicked, deletes a single selected row. The system will open a prompt asking if the row should be deleted.

'Yes' deletes the row.

'No' aborts deleting the row.

Import

Used to import parts from a spreadsheet.

If rows exist in the grid, the system will prompt to clear the grid before importing parts.

'Yes' opens a window to select the file to import.

'No' aborts the import.

When clicked, the consigned parts' 'Qty Available' is adjusted by the consignment quantities, based on the Account Consignment Option 'Insufficient Quantity' setting in the System General Setup screen.

If the 'Prompt to Update QOH for Consigned Parts' is unchecked (on the 'Consignments' tab on the Store General Setup screen):

Save the consignment updating the 'Start Date' and/or 'Update Date'.

Update the consigned quantity for all consigned parts; using the 'Insufficient Quantity' drop-down value (on the System General Setup screen) to determine the consigned quantity for each part.

Decrement the quantity available for all consigned parts.

Update the Part Ledger.

If the 'Prompt to Update QOH for Consigned Parts' is checked (on the 'Consignments' tab on the Store General Setup screen), the application displays a prompt with the text "Decrease QOH for consigned parts? WARNING: Selecting NO should only be used when entering consignments into the system that already existed in another system and QOH already reflects the current quantity for consigned parts."

Click the 'Cancel' button to return to the 'Consignment Setup' tab and there is no update for consigned parts.

Click the 'Yes' button and the system:

-

Saves the consignment updating the 'Start Date' and/or 'Update Date'.

-

Updates the consigned quantity for all consigned parts; using the 'Insufficient Quantity' drop-down value (on the System General Setup screen) to determine the consigned quantity for each part.

-

Decrements the quantity available for all consigned parts.

-

Updates the Part Ledger.

Click the 'No' button and the system:

-

Saves the consignment updating the 'Start Date' and/or 'Update Date'.

-

Updates the consigned quantity for all consigned parts; ignoring the 'Insufficient Quantity' drop-down value (on the System General Setup screen) to determine the consigned quantity for each part. Instead, only use the values of 'New Qty' to calculate the value of 'Consign Qty'.

-

Does not decrement the quantity available for all consigned parts.

-

Does not update the Part Ledger.

-

Updates the Audit Report indicating that an 'Update Stock' action occurred. Note: This audit tracking is especially important because the system does not update the Part Ledger for these consignment part updates.

Consignment Reports

Opens the Consignment Reports screen when clicked. See the Consignment Setup Report section for more.

Pick List / Return list

Prints the list of parts with a 'Consign Qty' on an open consignment. For edited consignments, the 'New Qty' values are not printed and only the edited parts will print.

The button is named 'Return List' when a closed consignment is displayed. See the Consignment Pick List / Consignment Return List section for more.

Procedure to Add a Consignment

To add a consignment, follow the steps below:

-

Import parts or enter parts in the 'Consignment Parts' data entry fields to add to a new consignment. All consign quantities will display in the 'New Qty' column in the 'Consignment Parts' grid.

-

NIF parts are not able to be added.

-

When finishing adding parts, if the physical parts have not yet been optionally removed from stock, clicking the 'Save' button will save the consignment, and will not update stock quantities. The consignment quantities will remain in the 'New Qty' column.

-

Click the 'Update Stock' button. The system will prompt "Are you sure?"

-

Click 'Yes' to close the prompt and:

-

Save the consignment.

-

Decrease the 'Qty Available' in the part table for all parts on the consignment.

-

Enter the current date in the 'Start Date' field.

-

Enter the current date in the 'Last Update' field.

-

Move the consigned quantity from 'New Qty' to the 'Consign Qty' for each part in the consignment.

-

Not affect part histories.

-

-

Or click 'No' to close the prompt and to abort updating the 'Qty Available'.

Procedure to Edit a Consignment

To edit a consignment, follow the steps below:

-

Once a consignment has been created and saved, it is possible to reload the consignment to edit it in several ways:

-

Increasing the 'Consign Qty' for a consigned part.

-

Decreasing the 'Consign Qty' for a consigned part.

-

Adding new items to the consignment.

-

Clearing all items from the 'Consignment Parts' grid for consignments in draft status.

-

Deleting existing items from the consignment for consignments in draft status.

-

-

To edit an existing part, double-click the row in the 'New Qty' field and enter a new quantity. The value entered in the 'New Qty' field overwrites the existing value in the 'Consign Qty' field when the 'Update Stock' process is complete.

-

To add a new part, enter the 'Line', 'P/N', and 'Consign Qty' in the data entry fields and press the 'Enter' key. The new part is added to the grid with the 'Consign Qty' in the 'New Qty' field.

-

To delete a part, enter a zero in the 'New Qty' field. When the 'Reset' button is clicked, or the consignment is re-displayed, the row no longer displays.

-

Click the 'Save' button to save changes without updating the stock, or

-

Click the 'Update Stock' button to save the changes and:

-

Save the consignment.

-

Increase / decrease the 'Qty Available' in the part table for added, edited or deleted parts only.

-

Enter the current date in the 'Last Update' field.

-

Move the consigned quantity from the 'New Qty' to the 'Consign Qty' for each part in the consignment.

-

Not affect part histories.

-