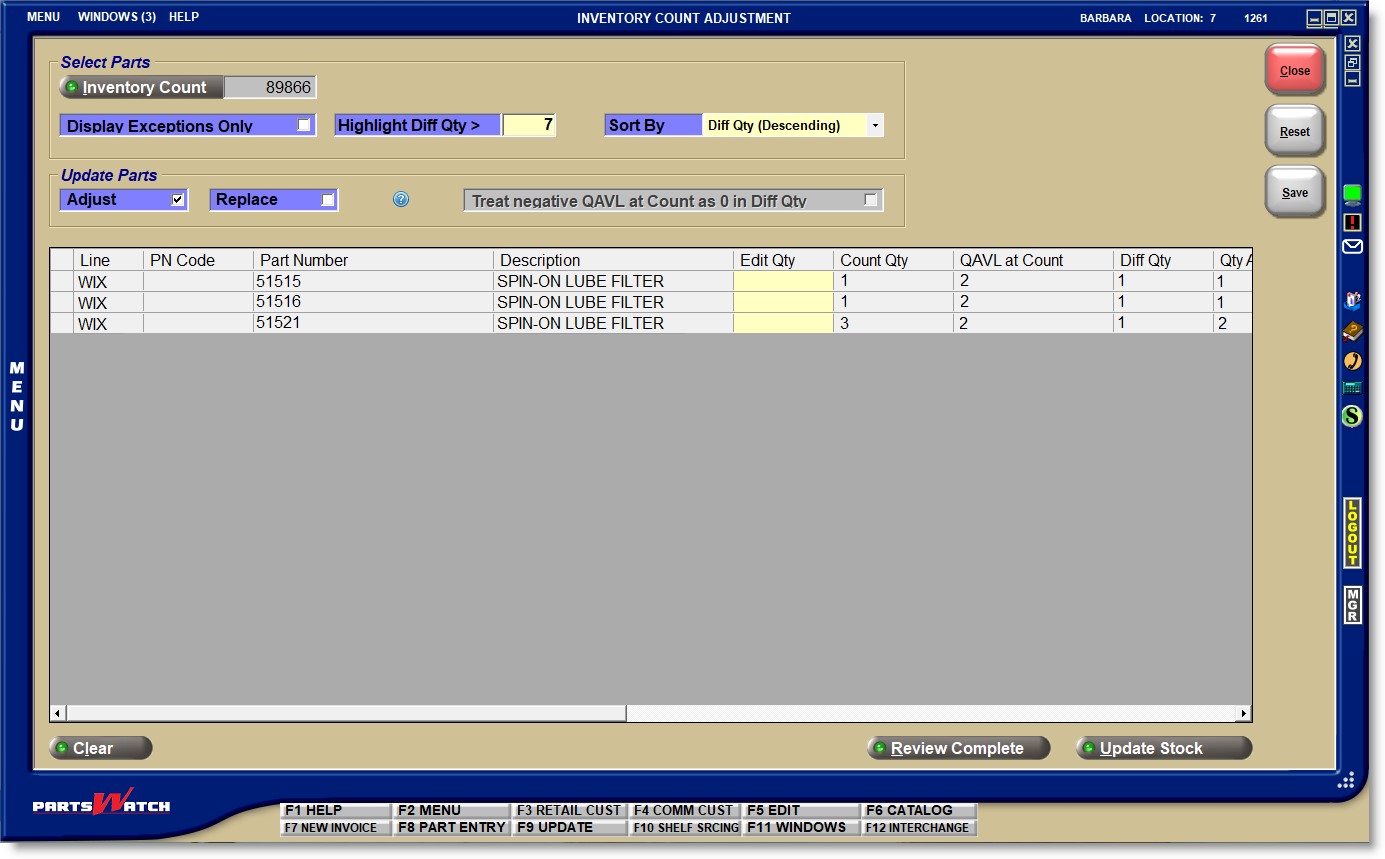

Inventory Count Adjustment

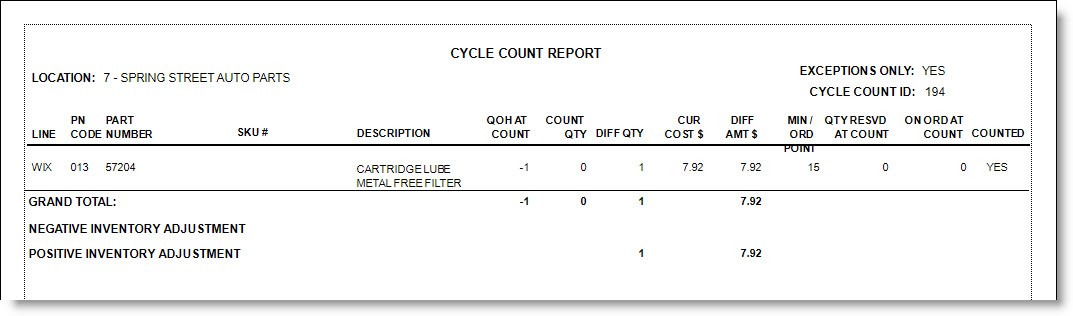

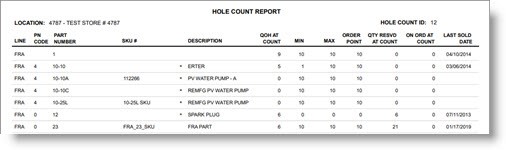

The wireless RF Gun application provides the ability to scan parts for a cycle count; including generating a cycle count report that compares scanned quantities to QOH in the store's inventory file for all parts scanned.

The 'Save Worksheet' button on the Inventory Count Report screen allows a worksheet to be saved using the selected criteria in order to count stock quantities.

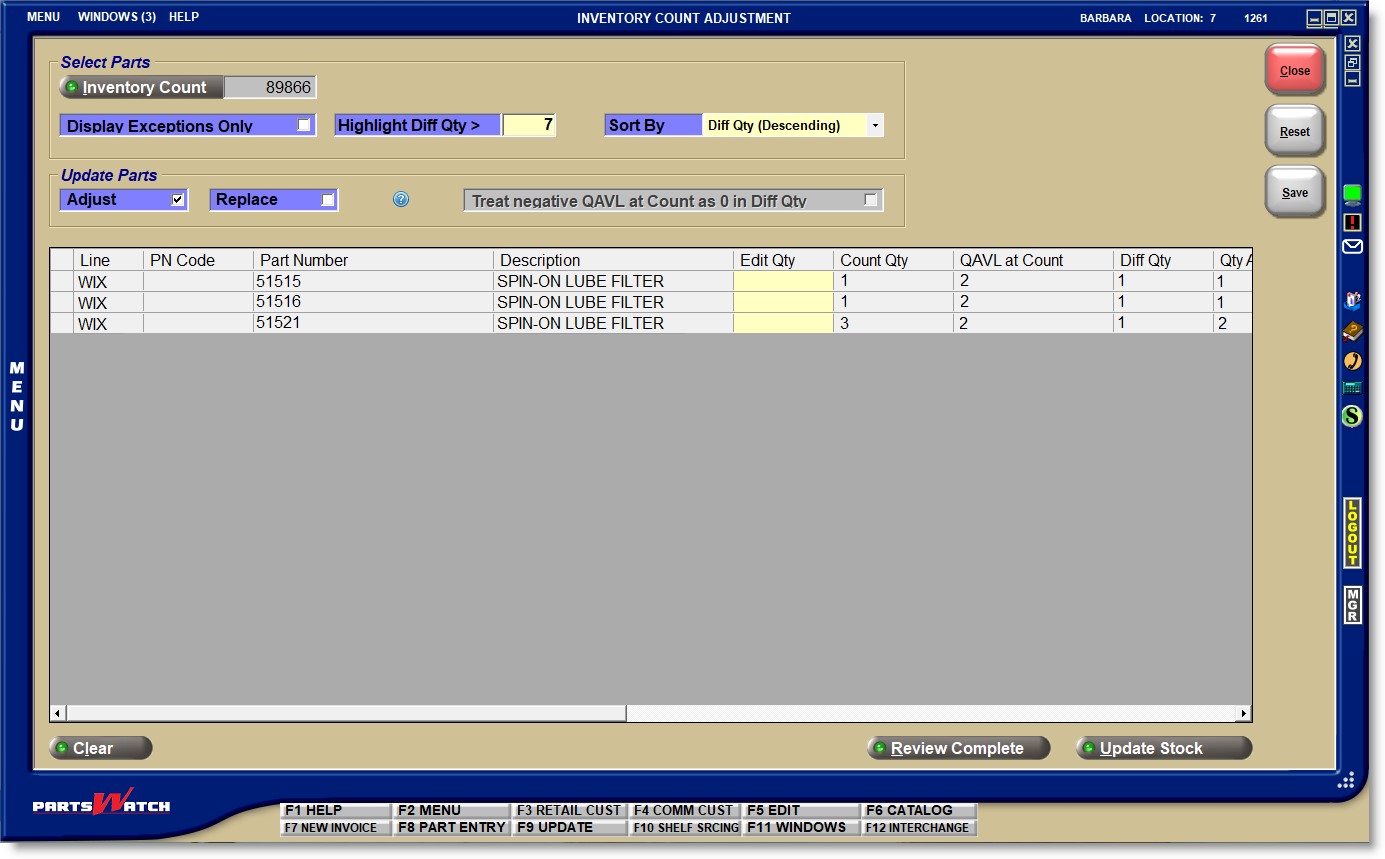

The Inevntory Count Adjustment (ICA) screen is used to review both the RF gun cycle count and the Inventory Count worksheet results, make corrections, and update all corrected stock quantities to the store's inventory file in order to complete the inventory counts.

Menu Path: Inventory, Part Entry, Inventory Count Adjustment, Inventory Count Adustment screen

Inventory Count Adjustment Setup

System General Setup screen

Menu Path: Controls, System, General Setup, System General Setup screen

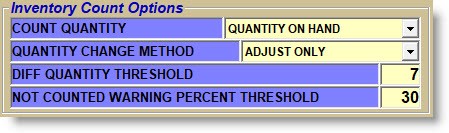

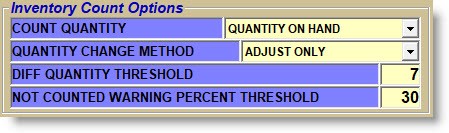

Inventory Count Options

Several setups are available to control how the Inevtory Count Adjustment (ICA) screen is used to review RF gun cycle count results.

Count Quantity

Click the drop-down and select whether counts are made against the 'Qty On Hand (QOH)' or the 'Qty Available'.

- 'Quantity on Hand' (default):

- Displays the column 'QOH' on the RF Device 'Cycle Count Entry' screen.

- Depending on security permissions, if a part's QOH value is edited on the RF Device 'Cycle Count Entry' screen, the part's current quantity available is updated in the store's inventory file.

- Compares the 'Count Qty' to 'QOH at Count' to calculate the 'Diff Qty'. Note: 'QOH at Count' is a snapshot copy of the part's current quantity on hand at the time of the count.

- 'Quantity Available':

- Display the column 'QAVL' on the RF Device 'Cycle Count Entry' screen.

- If a part's 'QAVL' value is edited on the RF Device 'Cycle Count Entry' screen (if security access permits), the system updates the part's current quantity available in the store's inventory file.

- On the Inventory Count Adjustment screen, compare 'Count Qty' to 'QAVL at Count' to calculate the 'Diff Qty'. Note: 'QAVL at Count' is a snapshot copy of the part's current quantity available at the time of the count.

Quantity Change Method

Click the drop-down and select how the inventory changes will be updated.

- 'Adjust and Replace' - Allows the 'Adjust' and 'Replace' fields to be edited on the INVENTORY COUNT ADJUSTMENT screen.

- 'Adjust Only' - Checks the 'Adjust' checkbox and disables it so that it cannot be changed on the INVENTORY COUNT ADJUSTMENT screen.

- 'Replace Only' - Unchecks the 'Adjust' checkbox and disables it so that it cannot be changed and enables the 'Replace' checkbox on the INVENTORY COUNT ADJUSTMENT screen.

Diff Quantity Threshold

Enter a value from '0' to '9999' (default '5').

When the Inventory Count Adjustment screen is open, after selecting an inventory count ID, for any parts displayed in the grid that contains a 'Diff Qty' value greater than the entered value (e.g. '5'), or less than the negative entered value (e.g. '-5'), the 'Diff Qty' value displays in red instead of black.

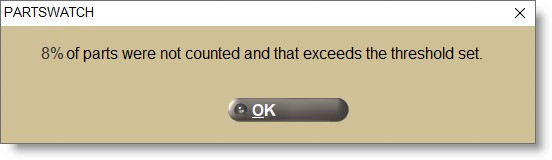

Not Counted Warning Percent Threshold

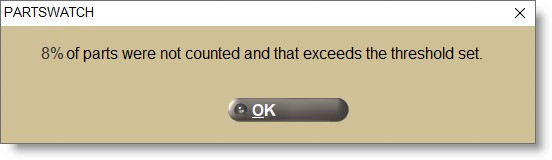

- Allows a value from '0' to '99' to be entered. (default '25').

- When the Inventory Count Adjustment screen is opened, after selecting an inventory count ID and parts are loaded into the grid, a pop-up message displays if the percentage of parts "not counted" exceeds the threshold.

- If set to '0' the warning pop-up does not display.

- Note: When the "counter" has used a cycle counting method of 'Line & PN Code Range' or 'Line & PN Code List', any part "not counted" can be for one of two reasons. Either the part has zero units in the bin "on the shelf", or the "counter" missed counting the part by mistake (e.g. the "counter" may have been missed counting a bin "on the shelf" that contained units.

- The Inventory Count Adjustment screen considers both reasons within the percentage "not counted". In the example above, the 8% includes both reasons. Therefore, it is very important to make sure the "counter" locates and counts all planned parts.

Help Definitions

The table below lists the terms and descriptions that pertain to this functionality.

Store's Inventory File - Store's "part table". When a count occurs, the application compares counted units to units "in stock" or in the store's inventory file.

Store's Virtual Inventory File - "NonSKU" table. This file contains "non-stocked" parts. A "non-stocked" part can be included in a count if any quantity available exists "on the shelf".

In-File Part - An "in-file" part is contained in the store's inventory file or the store's virtual inventory file.

Not-in-File (NIF) Part - A part that is not stocked in the store.

Inventory Count - A cycle count performed by scanning parts using the Add-on wireless RF Gun application or a manual count of parts performed using the Inventory Count Report/Worksheet. A count can include both stocked and NIF parts.

Count ID - A unique identifier for a cycle count.

Count Method - One of the four cycle count methods: 'Line & PN Code Range', 'Line & PN Code List', 'Scan Any Part', or 'Worksheet'.

"Counter" - An employee who counts parts.

Shelf Bin Location - A location "on the shelf" where individual parts, packs, boxes or cases of parts, or pallets of parts reside to be counted.

Parts "Not Counted" - Parts may be considered "not counted" for two reasons: either a) the shelf bin location was "empty" for a part (quantity available is zero or negative units), or b) the "counter" missed counting one or more shelf bin locations.

Inventory Count Adjustment (ICA) Screen - The screen used to review and edit all inventory count results before updating any part stock quantity discrepancies in the store’s inventory file "at once".

"Reviewer"/"Editor" - An employee who reviews and edits cycle counts on the INVENTORY COUNT ADJUSTMENT screen.

Select Parts

Inventory Count ('Alt'+'I')

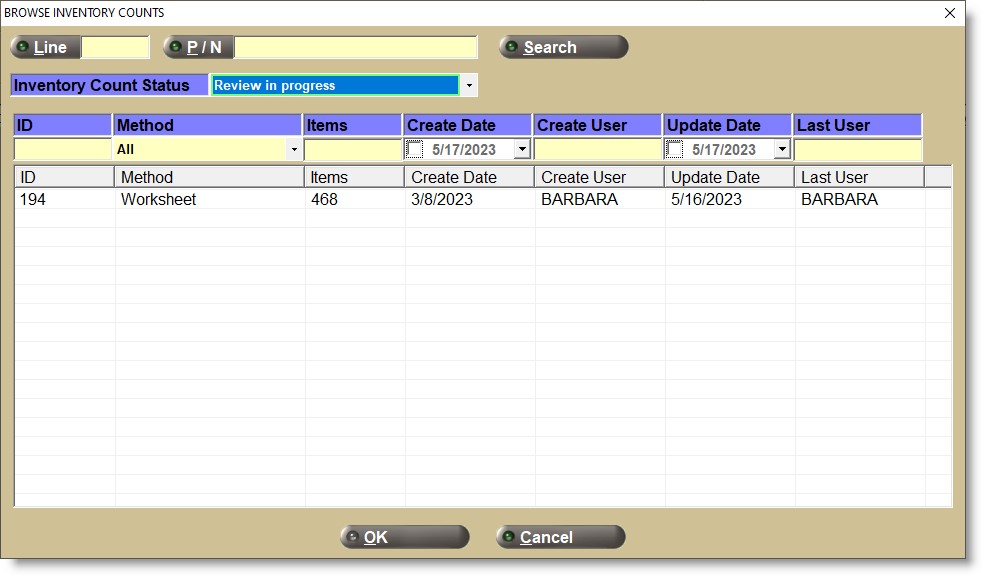

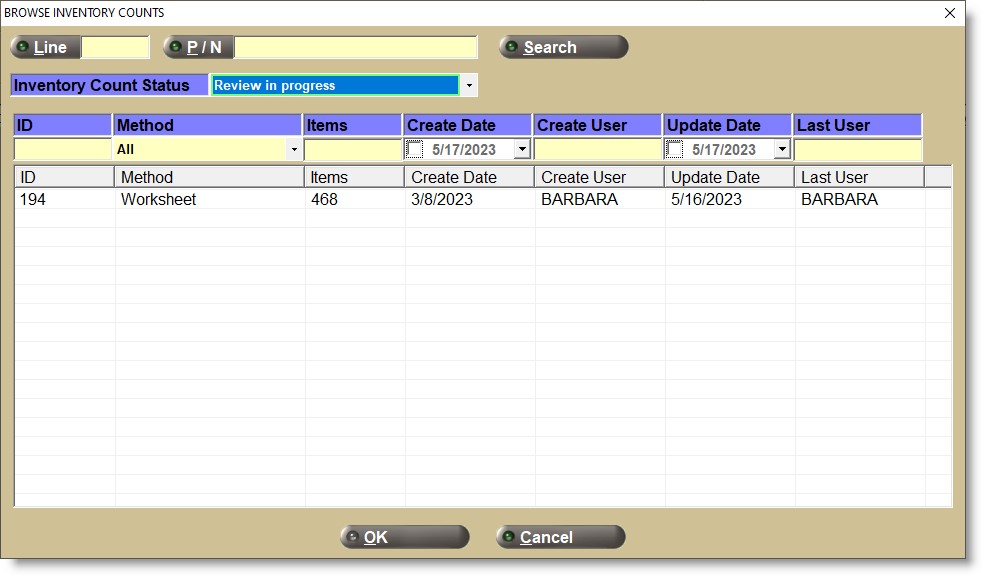

Click the 'Inventory Count' button to open the 'BROWSE INVENTORY COUNTS' window to select a count to review.

Browse Inventory Counts Window

The grid allows up to 1,000 available inventory count IDs for the login store that are in a 'FINAL' or 'FINAL-P' status. Note: Use the RF Gun device to change the status of a cycle count session from 'Incomplete' or 'Complete' to 'FINAL'.

To search for a count ID and narrow the results in the grid, enter a Line in the 'Line Code' field or click the 'Line Code' button to open the 'BROWSE LINE CODES' window to select a line code and/or enter a part in the 'P/N' field or click the 'P/N' button to open the 'FIND PART' window to select a part number, and click the 'SEARCH' button to display the results.

- Grid Columns

Enter a value in one or more of the data fields:

- ID - (inventory count ID) Filters by "begins-with text matching", i.e. type the number "8" and all count IDs that begin with the number 8 (e.g. 8, 84, 833) display.

- Method

- 'All'

- 'Any Part'

- 'Line & PN Code List'

- 'Line & PN Code Range'

- 'Worksheet'

- Items - Number of unique part numbers for the count ID and not the number of units for all parts in the inventory count. Filters by "exact matching", i.e. the exact number of items must be typed to match and display inventory count IDs that contain that number of items.

- Create Date - Date the inventory count ID was created.

- Create User - Employee login username that created the inventory count ID. Filters by "begins-with text matching", i.e. type the first character of the username to display all count IDs created by that employee.

- Update Date - Date the inventory count was last edited by either a "counter" or an "editor".

- Last User - Username login of the last employee who updated the inventory count as either a "counter" or an "editor". Filters by "begins-with text matching", i.e. type the first character of the username to display all count IDs last opened by that employee.

Display Exceptions Only

Used to determine whether to display all parts or only parts with a non-zero 'Diff Qty' (calculated difference between the 'Count Qty' and 'QAVL at Count' or 'QOH at Count'.)

- Checked (default) - Parts only display in the parts grid where the part has a non-zero Diff Qty value, regardless of the number of parts in the inventory count. Note: If no parts in the inventory count have a non-zero 'Diff Qty' value, a prompt displays stating: "There are no parts with exceptions in Inventory Count with ID: <ID>. Uncheck Display Exceptions Only to see all parts displayed." Click 'OK' and an empty grid displays.

- Unchecked - Displays all parts in the parts grid in the inventory count.

Highlight Diff Qty >

Displays the system 'DIFF QUANTITY THRESHOLD' setting and can be edited to a value between '0' and '9999'.

If any part displayed in the grid contains a 'Diff Qty' value greater than or less than the 'Highlight Diff Qty >' field the 'Diff Qty' displays in red. For example, if the 'Highlight Diff Qty >' field is '5', if a part has a 'Diff Qty' > '5' or less than '-5', the 'Diff Qty' will display in red.

Sort By

Click the drop-down and select the order to sort the parts in the grid:

- 'Diff Qty (Descending)' (default)

- 'Line', 'PN CODE', 'Part #'

- 'Line', 'Part #'

- 'Scan Sequence #'

Note: Typically, a count is for "stocked" parts in the store's inventory file. However, some "non-stocked" or NIF parts recently sold and returned to the store may also exist in the store's inventory file and are included in the count if they have a quantity available "on the shelf".

When a "counter" uses a cycle counting method of 'Line & PN Code Range' or 'Line & PN Code List', "non-stocked" parts will be "counted" in the Count 'ID' if they have 'QAVL'/'QOH' in the store's inventory file, or they were scanned or manually entered on the RF Gun Cycle Count screen.

"Non-stocked" parts are excluded from the Count 'ID', and will be excluded from being loaded on the ICA screen if all of the following criteria are met:

- The part has no stocking level ('Min', 'Max', and 'Order Point' are all zero)

- The part has no Quantity on Hand ('Quantity Available' and 'Quantity Reserved' are both zero)

- The part was "not counted" ('Count Qty' is zero).

Note: Since these parts are not loaded in the grid, the 'Not Counted Warning Percent Threshold' calculation does not consider these parts.

Update Parts

Adjust/Replace

The 'Adjust'/'Replace' checkboxes are used to determine whether to add/subtract the 'Edit Qty' from the 'Count Qty' or to replace the 'Count Qty' with the 'Edit Qty'. Only one can be checked at a time and depends on the system 'QUANTITY CHANGE METHOD' setting to determine field availability. If the 'Quantity Change Method' setting is set to:

- 'Adjust and Replace' - 'Adjust' is checked, however, 'Replace' can be checked as needed.

- 'Adjust Only' - 'Adjust' is checked and disabled. It cannot be unchecked.

- 'Replace Only' - 'Replace' is checked and disabled. It cannot be unchecked.

'Adjust' vs. 'Replace'

'Adjust' is always safer to use because the 'Update Stock' button can be clicked at any time of the day or night, even if store operations are buying and selling products at the same time as the update.

'Replace' should always be used when the store is closed.

Note: Regardless of which option is used, PartsWatch advises any part 'Qty Avail' updates to be performed during "off hours", just to be safe, when the store's inventory file "is not moving".

For example, if a cycle count was performed last night and the physical scanned inventory was 9 for a part on the shelf. This amount was 1 less than the part's 'QOH' of 10 in the store's inventory file (based upon a "snapshot" copy of the part's 'QOH' taken at the time the part was scanned in the cycle count session).

With the 'Adjust' option, using the example above, when the 'Update Stock' button is clicked, the system will subtract 1 from the part's current 'QOH' value in the store's inventory:

- If the 'Update Stock' button is clicked the following morning, and the current 'QOH' value is still 10, the system will decrease the current 'QOH' value to 9.

- However, if two units were sold in the morning before the 'Update Stock' button was clicked, the current 'QOH' value would already be decreased to 8. Then, when the 'Update Stock' button was clicked, the part's 'QOH' is decreased by 1 resulting in a current 'QOH' value of 7 (which matches the 9 scanned physical units minus the 2 units sold).

- Using a final example, if two units were returned by a customer in the morning, and two other units were received from a vendor PO/ASN in the same morning before the 'Update Stock' button was clicked, the current 'QOH' value would already be increased to 14. Then, when the 'Update Stock' button is clicked, the current 'QOH' value of 14 is decreased by 1 resulting in a current 'QOH' value of 13 (which matches the 9 scanned physical units plus the 2 units returned plus the 2 units received).

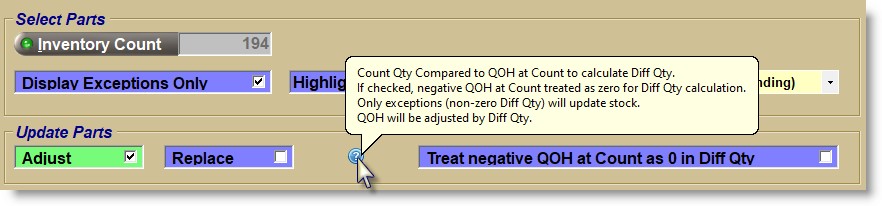

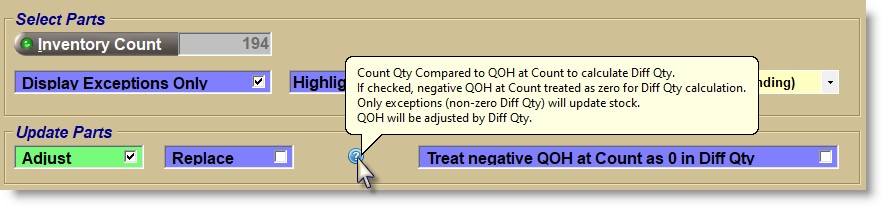

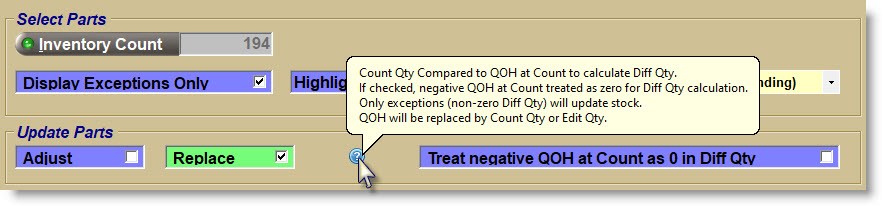

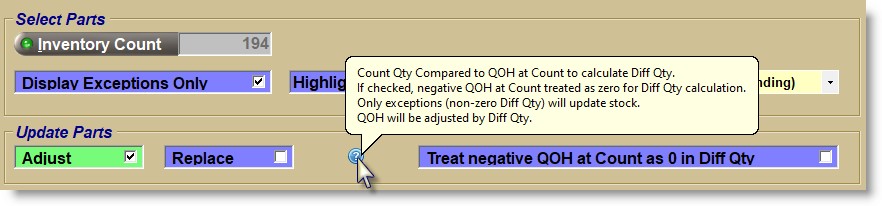

Help Icon

The help icon (circled question mark) to the right of the 'Replace' checkbox displays help information with a mouse-over on the icon.

The help icon defines how the 'Diff Qty' column in the grid is calculated, and which columns in the grid update the part's current quantity available or quantity on hand in the store's inventory file when the 'Update Stock' button is clicked:

Treat negative <count quantity> at Count as 0 in Diff Qty

The field is disabled and unchecked before selecting a count 'ID' and the label displayed is based upon the value of the system 'Count Quantity' setting:

- If set to 'Quantity Available', the label is set to 'Treat negative QAVL at Count as 0 in Diff Qty', and if the checkbox is:

-

Unchecked (default) - The formula for calculating the grid 'Diff Qty' uses any negative values that exist for the grid 'QAVL at Count' field.

-

Checked - The formula for calculating the grid 'Diff Qty' replaces any negative values for the 'QAVL at Count' field with zeroes.

- If set to 'Quantity on Hand', the label is set to 'Treat negative QOH at Count as 0 in Diff Qty', and if the checkbox is:

-

Unchecked (default) - The formula for calculating the grid 'Diff Qty' uses any negative values that exist in the grid 'QOH at Count' field.

-

Checked - The formula for calculating the grid 'Diff Qty' replaces any negative values for the grid ‘QOH at Count’ with zeroes.

Parts Grid

After selecting a count 'ID' from the 'Browse Inventory Counts' window, all parts, or only exceptions display in the grid depending on the value of the 'Display Exceptions Only' checkbox.

By default, parts are sorted by 'Diff Qty (Descending)' from highest to lowest, therefore, parts with the biggest "overage" discrepancy are displayed at the top of the grid. Change the 'Sort By' field to re-sort the order.

The first three columns in the parts grid ('Line', 'PN Code', and 'Part Number') are "frozen" and always display when scrolling horizontally to the right to display additional columns.

Clicking a column header re-sorts the values following standard column sort functionality.

-

If a user unchecks the 'Display Exceptions Only' checkbox (overriding the default), display all parts in the inventory count, maintaining the same sort.

-

If a user selects/re-checks the 'Display Exceptions Only' checkbox:

- Display only those parts in the inventory count where 'Diff Qty' is non-zero, maintaining the same sort.

- If there are no parts in the grid with a non-zero 'Diff Qty', display a prompt "There are no parts with exceptions in Inventory Count with ID: <ID>. Uncheck Display Exceptions Only to see all parts displayed.", and an 'OK' button.

- When a user clicks the 'OK' button, return the user to the screen and display an empty grid with no parts displayed.

Grid Columns

- 'Line'

- 'PN Code'

- 'Part Number'

- 'Description' - From the store's inventory file or virtual inventory file. A blank value displays for NIF parts. 'Description 2' does not display.

- 'Edit Qty' - Displays blank values or any previously saved values.

The field is enabled / disabled depending on the 'Inventory Count Status' of the count ID:

- 'To be reviewed' or 'Review in progress', the 'Edit Qty' column is enabled to enter, edit, and clear values.

- 'Review complete discarded', 'Review complete no updates', or 'Review complete with updates', the 'Edit Qty' column is disabled and not available for editing.

- 'Count Qty' - Quantity scanned or entered from the inventory count.

- 'QAVL at Count'/'QOH at Count' - The column label is either 'QAVL at Count' or 'QOH at Count' depending on the system 'Count Quantity' setting at the time of the count and displays the part's quantity available or quantity on hand from the inventory file when the part was first scanned or entered during the inventory count.

- 'Diff Qty' - The calculated difference between the 'Count Qty' and 'QAVL at Count' or 'QOH at Count'.

The 'Diff Qty' displays in red if it is greater than or less than the 'Highlight Diff Qty >' threshold value.

When the grid is first populated the 'Diff Qty' is calculated using the following formula:

- 'Count Qty' minus 'QAVL at Count' if the count ID's 'Count Quantity' is 'Quantity Available' and the 'Treat negative QAVL as 0 in Diff Qty' checkbox is unchecked.

- 'Count Qty' minus '0' if the count ID's 'Count Quantity' is 'Quantity Available' and the 'Treat negative QAVL as 0 in Diff Qty' checkbox is checked and 'QAVL at Count' has a negative value.

- 'Count Qty' minus 'QOH at Count' if the count ID's 'Count Quantity is 'Quantity on Hand' and the 'Treat negative QAVL as 0 in Diff Qty' is unchecked.

- 'Count Qty' minus '0' if the count ID's 'Count Quantity' is 'Quantity on Hand' and the 'Treat negative QAVL as 0 in Diff Qty' is checked and 'QOH at Count' has a negative value.

Note: Discrepancies (non-zero 'Diff Qty') occur when the number of units "counted" is different from the number of units that are supposed to be "on the shelf" as reflected in the store's inventory file. Review and enter values in 'Edit Qty' to correct discrepancies.

Enter a value in the 'Edit Qty' and the 'Diff Qty' is re-calculated using the following formula:

- 'Edit Qty' minus 'QAVL at Count' if the count ID's 'Count Quantity' is 'Quantity Available' and the 'Treat negative QAVL as 0 in Diff Qty' is unchecked.

- 'Edit Qty' minus '0' if the count ID's 'Count Quantity' is 'Quantity Available' and the 'Treat negative QAVL as 0 in Diff Qty' is checked and 'QAVL at Count' has a negative value.

- 'Edit Qty' minus 'QOH at Count' if the count ID's 'Count Quantity' is 'Quantity on Hand' and the 'Treat negative QAVL as 0 in Diff Qty' is unchecked.

- 'Edit Qty' minus '0' if the count ID's 'Count Quantity' is 'Quantity on Hand' and the 'Treat negative QAVL as 0 in Diff Qty' is checked and 'QOH at Count' has a negative value.

If a value previously entered is edited, the 'Diff Qty' is recalculated using the formula:

- 'Count Qty' minus 'QAVL at Count' if the count ID's 'Count Quantity' is 'Quantity Available' and the 'Treat negative QAVL as 0 in Diff Qty' is unchecked.

- 'Count Qty' minus '0' if the count ID's 'Count Quantity' is 'Quantity Available' and the 'Treat negative QAVL as 0 in Diff Qty' is checked and 'QAVL at Count' has a negative value.

- 'Count Qty' minus 'QOH at Count' if the count ID's 'Count Quantity' is 'Quantity on Hand' and the 'Treat negative QAVL as 0 in Diff Qty' is unchecked.

- 'Count Qty' minus '0' if the count ID's 'Count Quantity' is 'Quantity on Hand' and the 'Treat negative QAVL as 0 in Diff Qty' is checked and 'QOH at Count' has a negative value.

Note: The color of the 'Diff Qty' may also change based upon the re-calculation of the 'Diff Qty' value.

- 'QOH' - Current Qty Available plus Qty Reserved aggregated together for the part in the store's inventory file.

- 'Qty Avail' - Current quantity available for the part in the store's inventory file.

- 'Qty Resvd' - Current quantity reserved for the part in the store's inventory.

- 'Last QOH Update Date' - The most recent date from the Part Ledger that the system updated the part's quantity available.

- (cost) - Displays the 'Custom Name' from the Field Name Setup screen for the price level set up in the 'Part Pricing Default' setting and the valve for the level.

The 'Cost and Report Pricing' security proc controls whether or not cost information displays in the cost column in the part grid.

- (stocking level) - Displays the stocking level set up as the system Stocking Level and the value.

Total Parts

The text 'Total Parts:' and the total number of parts in the grid are displayed below the grid.

Exception Parts

The text 'Exception Parts:' and the total number of part exceptions in the grid display below the grid.

Save Button

Click the 'Save' button to save any changes entered in the 'Edit Qty' column without updating the edits to stock. The screen will not reset.

If one or more 'Edit Qty' values have been entered, pressing the 'Esc' key or clicking the 'Close' button without first clicking the 'Save' button will prompt, "Save changes?". Answer:

-

'Yes' to save changes and close or reset the screen.

-

'No' to close or reset the screen without saving changes.

-

'Cancel' returns focus to the ICA screen without resetting or closing.

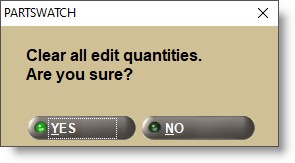

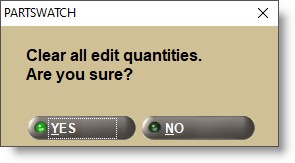

Clear Button

Click the 'Close' button to clear all 'Edit Qty' values (before clicking the 'Update Stock' or 'Review Complete' button and the system prompts "Clear all edit quantities. Are you sure?"

Answer:

Note: To clear only new 'Edit Qty' values without clearing saved values, click the 'Reset' button instead of the 'Clear' button.

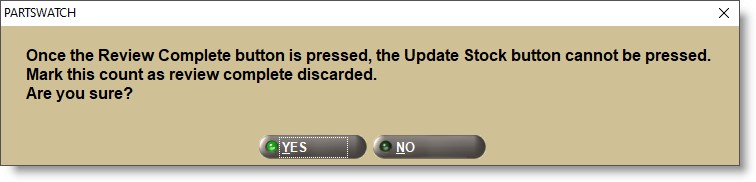

Review Complete Button

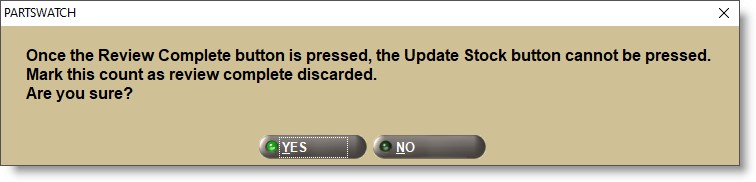

Click the 'Review Complete' ('Alt'+'R') button and a pop-up opens with one of two different text messages:

-

If there are any parts with non-zero 'Diff Qty' values, "Once the Review Complete button is pressed, the Update Stock button cannot be clicked. Mark this count as review complete discarded. Are you sure?" Answer:

-

'Yes' to change the 'Review Status' to 'Review complete discarded', auto-save any unsaved changes to 'Edit Qty' values, and reset the screen.

-

'No' returns focus to the ICA screen without making changes.

-

If all parts contain zero 'Diff Qty' values, "Once the Review Complete button is pressed, the Update Stock button cannot be pressed. Mark this count as review complete no updates. Are you sure?" Answer:

-

'Yes' to change the 'Review Status' to 'Review complete no updates', auto-save any unsaved changes to 'Edit Qty' values and the value of the 'Treat negative QAVL at Count as 0 in Diff Qty ' checkbox, and reset the screen.

-

'No' returns focus to the ICA screen without making changes.

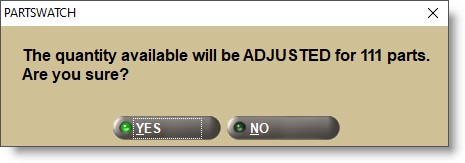

Update Stock Button

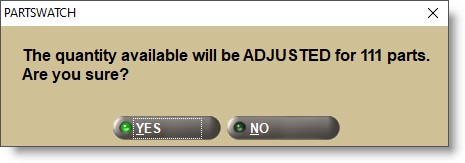

Click the 'Update Stock' ('Alt'+'U') button to initiate the stock update and a prompt opens with the number of parts that will be adjusted. Answer:

Note: An inventory count can only have stock updated one time so if the same Count 'ID' is re-selected from the 'BROWSE INVENTORY COUNT' pop-up, the Count 'ID's 'Inventory Status' will be 'Review complete with updates' and the count 'ID' will display but the 'Update Stock' button will not be enabled.

Stock Updates - Adjust

When 'Adjust' is selected, the part's current 'Qty Avail' is updated in the store's inventory file if any part has a non-zero 'Diff Qty'. Note: Parts with a zero 'Diff Qty' do not update the part's 'Qty Avail' in the store's inventory file.

The following calculations are used when the inventory count's 'Count Quantity' is 'Quantity Available' and the 'Treat negative QAVL at Count as 0 in Diff Qty' is unchecked:

- 'Diff Qty' = 'Count Qty' - 'QAVL at Count' (if 'Edit Qty' is blank)

- 'Diff Qty' = 'Edit Qty' - 'QAVL at Count' (if 'Edit Qty' has a value)

- 'Qty Avail' = current 'Qty Avail' + 'Diff Qty'

The following calculations are used when the inventory count's 'Count Quantity' is 'Quantity Available', the 'Treat negative QAVL at Count as 0 in Diff Qty' is checked, and the 'QAVL at Count' is positive:

- 'Diff Qty' = 'Count Qty' - 'QAVL at Count' (if 'Edit Qty' is blank)

- 'Diff Qty' = 'Edit Qty' - 'QAVL at Count' (if 'Edit Qty' has a value)

- 'Qty Avail' = current 'Qty Avail' + 'Diff Qty'

The following calculations are used when the inventory count's 'Count Quantity' is 'Quantity Available', the 'Treat negative QAVL at Count as 0 in Diff Qty' is checked, and the 'QAVL at Count' is zero or negative:

- 'Diff Qty' = 'Count Qty' - 0 (if 'Edit Qty' is blank)

- 'Diff Qty' = 'Edit Qty' - 0 (if 'Edit Qty' has a value)

- 'Qty Avail' = current 'Qty Avail' + 'Diff Qty'

The following calculations are used when the inventory count's 'Count Quantity' is 'Quantity on Hand' and the 'Treat negative QOH at Count as 0 in Diff Qty' is unchecked:

- 'Diff Qty' = 'Count Qty' - 'QOH at Count' (if 'Edit Qty' is blank)

- 'Diff Qty' = 'Edit Qty' - 'QOH at Count' (if 'Edit Qty' has a value)

- 'Qty Avail' = current 'Qty Avail' + 'Diff Qty'

The following calculations are used when the inventory count's 'Count Quantity' is 'Quantity on Hand', the 'Treat negative QOH at Count as 0 in Diff Qty' is checked, and the 'QOH at Count' is positive:

- 'Diff Qty' = 'Count Qty' - 'QOH at Count' (if 'Edit Qty' is blank)

- 'Diff Qty' = 'Edit Qty' - 'QOH at Count' (if 'Edit Qty' has a value)

- 'Qty Avail' = current 'Qty Avail' + 'Diff Qty'

The following calculations are used when the inventory count's 'Count Quantity' is 'Quantity on Hand', the 'Treat negative QOH at Count as 0 in Diff Qty' is checked, and the 'QOH at Count' is zero or negative:

- 'Diff Qty' = 'Count Qty' - 0 (if 'Edit Qty' is blank)

- 'Diff Qty' = 'Edit Qty' - 0 (if 'Edit Qty' has a value)

- 'Qty Avail' = current 'Qty Avail' + 'Diff Qty'

The Part Ledger quantity change value is equal to the calculated 'Diff Qty' value for each part.

The part's current 'Qty Avail' is updated (increased or decreased) by the amount of the Part Ledger quantity change value.

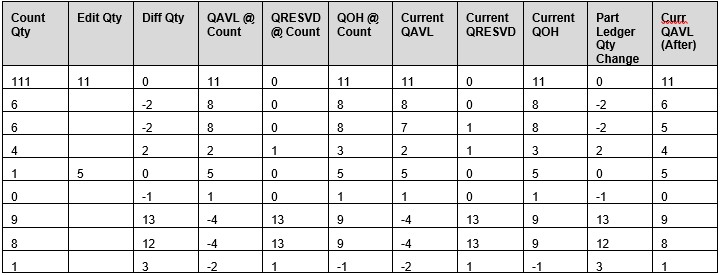

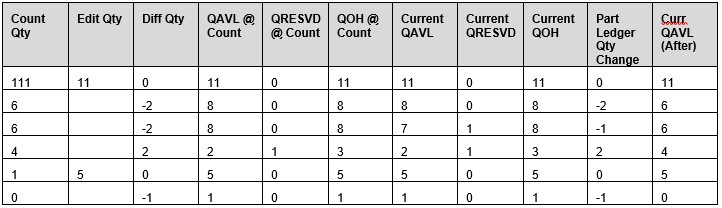

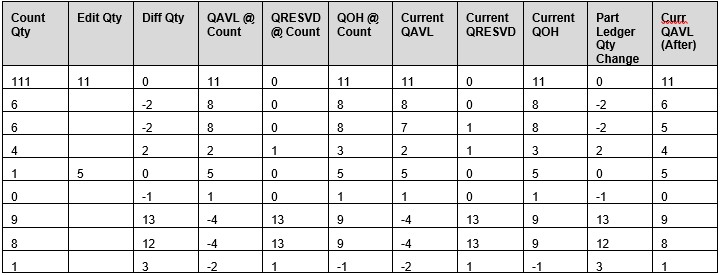

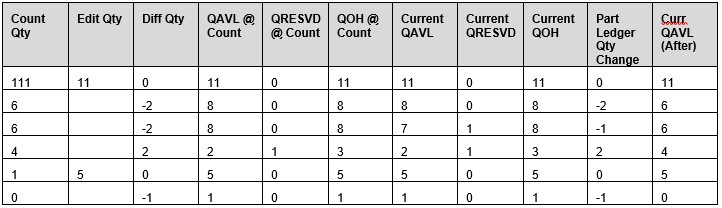

The following have the 'Adjust' checkbox checked, 'Count Quantity' set to 'Quantity Available', and the 'Treat negative QAVL at Count as 0 in Diff Qty' unchecked:

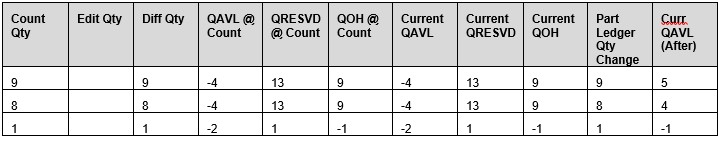

The following have the 'Adjust' checkbox checked, 'Count Quantity' set to 'Quantity Available' and the 'Treat negative QAVL at Count as 0 in Diff Qty' checked:

Note: If unsure that the 'Count Qty' is correct, enter a value for 'Edit Qty' that is equal to the 'QAVL at Count' or 'QOH at Count' to recalculate the 'Diff Qty' to zero. This will result in no change made to the part's 'Qty Avail' when the 'Update Stock' button is clicked.

Note: When an 'Edit Qty' value has been entered to set a parts 'Diff Qty' to zero, if the 'Display Exceptions Only' checkbox is checked, that part will still be visible. However, if it is unchecked and then re-checked the part will be hidden. Therefore, the part's 'Qty Avail' is not changed using the ICA screen and may need to be subsequently reviewed and corrected using another application function: e.g. the Main Part Entry ('F8') screen, Quantity Adjust screen, or DFIU. Only click the 'Update Stock' button once for any inventory count.

Stock Updates - Replace

When 'Adjust' is selected, the part's current 'Qty Avail' in the store's inventory file is updated if any part has a non-zero 'Diff Qty'.

Note: Parts with a zero 'Diff Qty' will not update the part's current 'Qty Avail' in the store’s inventory file.

Note: When the 'Replace' checkbox is checked, the 'Treat negative QAVL at Count ' checkbox, whether checked or unchecked, only affects the calculation of 'Diff Qty', which determines the number of exception parts to be updated.

Note: The 'Treat negative QAVL at count as 0 in Diff Qty' checkbox has no impact on the current 'Qty Avail', 'Qty Resvd', and 'QOH' amounts which always retain their negative value in the calculation of the updated 'Qty Avail'.

The following calculations are used when the inventory count's 'Count Quantity' is 'Quantity Available', the 'Treat negative QAVL at Count as 0 in Diff Qty' is unchecked, and 'Edit Qty' is blank:

- 'Diff Qty' = 'Count Qty' - 'QAVL at Count'

- Part Ledger quantity change = 'Count Qty' - current 'Qty Avail'

- 'Qty Avail' = 'Count Qty'

- The following calculations are used when the inventory count’s 'Count Quantity' is 'Quantity Available', the 'Treat negative QAVL at Count as 0 in Diff Qty' is unchecked, and 'Edit Qty' has a value:

- 'Diff Qty' = 'Edit Qty' - 'QAVL at Count'

- Part Ledger quantity change = 'Edit Qty' - current 'Qty Avail'

- 'Qty Avail' = 'Edit Qty'

The following calculations are used when the inventory count's 'Count Quantity' is 'Quantity Available', the 'Treat negative QAVL at Count is 0 in Diff Qty' is checked, the 'QAVL at Count' is positive and 'Edit Qty' is blank:

- 'Diff Qty' = 'Count Qty' - 'QAVL at Count'

- Part Ledger quantity change = 'Count Qty' - current 'Qty Avail'

- 'Qty Avail' = 'Count Qty'

The following calculations are used when the inventory count's 'Count Quantity' is 'Quantity Available', the 'Treat negative QAVL at Count is 0 in Diff Qty' is checked, the 'QAVL at Count' is positive, and 'Edit Qty' has a value:

- 'Diff Qty' = 'Edit Qty' - 'QAVL at Count'

- Part Ledger quantity change = 'Edit Qty' - current 'Qty Avail'

- 'Qty Avail' = 'Edit Qty'

The following calculations are used when the inventory count's 'Count Quantity' is 'Quantity Available', the 'Treat negative QAVL at Count is 0 in Diff Qty' is checked, the 'QAVL at Count' is zero or negative, and 'Edit Qty' is blank:

- 'Diff Qty' = 'Count Qty' - 0

- Part Ledger quantity change = 'Count Qty' - current 'Qty Avail'

- 'Qty Avail' = 'Count Qty'

The following calculations are used when the inventory count's 'Count Quantity' is 'Quantity Available', the 'Treat negative QAVL at Count is 0 in Diff Qty' is checked, the 'QAVL at Count' is zero or negative, and 'Edit Qty' has a value:

- 'Diff Qty' = 'Edit Qty' - 0

- Part Ledger quantity change = 'Edit Qty' - current 'Qty Avail'

- 'Qty Avail' = 'Edit Qty'

The following calculations are used when the inventory count's 'Count Quantity' is 'Quantity on Hand', the 'Treat negative QOH at Count is 0 in Diff Qty' is unchecked, and 'Edit Qty' is blank:

- 'Diff Qty' = 'Count Qty' - 'QOH at Count'

- Part Ledger quantity change = 'Count Qty' - current 'QOH'

- 'Qty Avail' = current 'Qty Avail' + Part Ledger quantity change

The following calculations are used when the inventory count's 'Count Quantity' is 'Quantity on Hand', the 'Treat negative QOH at Count is 0 in Diff Qty' is unchecked, and 'Edit Qty' has a value:

- 'Diff Qty' = 'Edit Qty' - 'QOH at Count'

- Part Ledger quantity change = 'Edit Qty' - current 'QOH'

- 'Qty Avail' = current 'Qty Avail' + Part Ledger quantity change

The following calculations are used when the inventory count's 'Count Quantity' is 'Quantity on Hand', the 'Treat negative QOH at Count is 0 in Diff Qty' is checked, the 'QOH at Count' is positive, and 'Edit Qty' is blank:

- 'Diff Qty' = 'Count Qty' - 'QOH at Count'

- Part Ledger quantity change = 'Count Qty' - current 'QOH'

- 'Qty Avail' = current 'Qty Avail' + Part Ledger quantity change

The following calculations are used when the inventory count's 'Count Quantity' is 'Quantity on Hand', the 'Treat negative QOH at Count is 0 in Diff Qty' is checked, the 'QOH at Count' is positive, and 'Edit Qty' has a value:

- 'Diff Qty' = 'Edit Qty' - 'QOH at Count'

- Part Ledger quantity change = 'Edit Qty' - current 'QOH'

- 'Qty Avail' = current 'Qty Avail' + Part Ledger quantity change

The following calculations are used when the inventory count's 'Count Quantity' is 'Quantity on Hand', the 'Treat negative QOH at Count is 0 in Diff Qty' is checked, the 'QOH at Count' is zero or negative, and 'Edit Qty' is blank:

- 'Diff Qty' = 'Count Qty' - 0

- Part Ledger quantity change = 'Count Qty' - current 'QOH'

- 'Qty Avail' = current 'Qty Avail' + Part Ledger quantity change

The following calculations are used when the inventory count's 'Count Quantity' is 'Quantity on Hand', the 'Treat negative QOH at Count is 0 in Diff Qty' is checked, the 'QOH at Count' is zero or negative, and 'Edit Qty' has a value:

- 'Diff Qty' = 'Edit Qty' - 0

- Part Ledger quantity change = 'Edit Qty' - current 'QOH'

- 'Qty Avail' = current 'Qty Avail' + Part Ledger quantity change

- The part's current 'Qty Avail' is updated (increased or decreased) by the amount of the Part Ledger quantity change value.

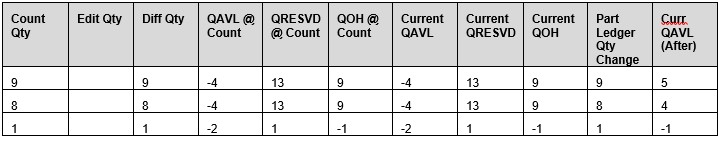

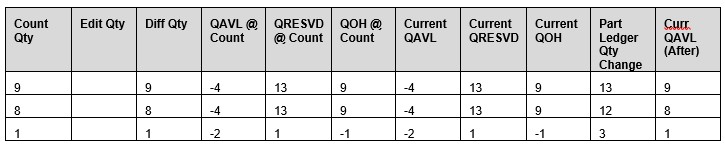

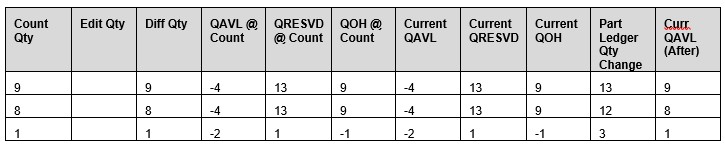

The following have the 'Replace' checkbox checked, 'Count Quantity' set to 'Quantity Available', and 'Treat negative QAVL at Count as 0 in Diff Qty' unchecked:

The following have the 'Replace' checkbox checked, 'Count Quantity' set to 'Quantity Available', and 'Treat negative QAVL at Count as 0 in Diff Qty' checked:

Possible Cycle Count Errors

- "Counter" errors. For example, assuming that there were 29 units of a part on a pallet. The "counter" scans one unit, and then uses the manual entry on the RF Device application to enter '29' but instead enters '39' by mistake.

- Quantity counts. For example, reserved quantities are counted when only available quantities should be counted, or when the quantity on hand is counted and reserved quantities are missed.

- "UPC barcode" mistakes including:

- The Pack quantity in the barcode table is incorrect, leading to an invalid scanned quantity. For example, the bar code pack quantity might be 12 when scanning a 'Pack' barcode, resulting in a scanned quantity of 12, when there are only 8 items per pack.

- Multiple bar codes are available to scan at a shelf bin location; a barcode for an 'Each' unit, a barcode for a 'Box' unit (6 units per box), and a barcode for a 'Case' unit (10 boxes per case or 60 individual units per case). The "counter" must be careful to get the counting correct, especially if there is a "blind count" where the part's 'QOH' or 'QAVL' is not displayed on the RF device.

- The UPC barcode for a 'Box' quantity unit scanned could be 20 (20 units per box) but there are only 18 units left in the actual box. The "box may have been opened" and 2 units may have been sold or removed for other reasons. If the "counter" does not carefully check the inside of all open boxes, there may be an incorrect scanned quantity.

Correct Now versus Correct Later

If there isn't time to resolve a discrepancy by performing a "re-count", the 'Edit Qty' can be set to equal to the 'QOH at Count' or 'QAVL at Count' to ensure that no changes are made to the part's "current" 'Qty Avail' in the store's inventory file when the 'Update Stock' button is clicked.

For example, when the screen opens, if the 'Count Qty' = 1000, the 'QAVL' at Count = 10, and the "current" 'Qty Avail' = 10, then it looks like a typing error. In this instance, the 'Edit Qty' can be set to 10 (whether using the 'Replace' or 'Adjust Qty Available') so that no change is made to the part's 'Qty Avail' in the store's inventory file.

Note: It is important to remember which parts were not corrected when the 'Update Stock' button is clicked because the button can only be clicked once for a count 'ID'. The parts not corrected now can be corrected later using several other application screens or functions: e.g. the Main Part Entry ('F8') screen, the Quantity Adjust screen or DFIU.

Part Ledger Report

The quantity available change for all parts updated in the store's inventory file from the Inventory Count Adjustment screen are tracked in the Part Ledger Report.

Use the 'Changed By' drop-down value of 'Count' to output the inventory changes.

The report output prints 'A' for "adjust" in the 'By' column and the text of 'Count' in the 'Detail' column.

Audit Report

When the 'Update Stock' button is clicked, an audit record is captured for the Audit Report of who (login username) clicked the 'Update Stock' button, at what date/time, and indicates the number of parts updated and the type of update of 'Adjust' or 'Replace'.

Inventory Count Adjustment Reporting

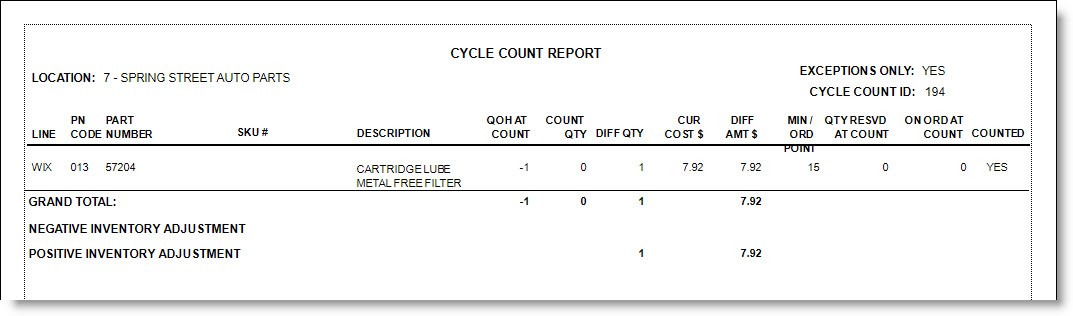

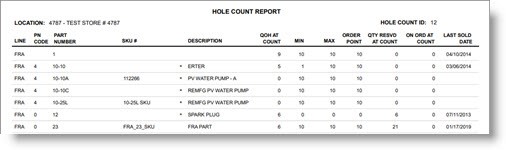

Inventory Count Adjustments are tracked to the:

![]()

![]()

![]()